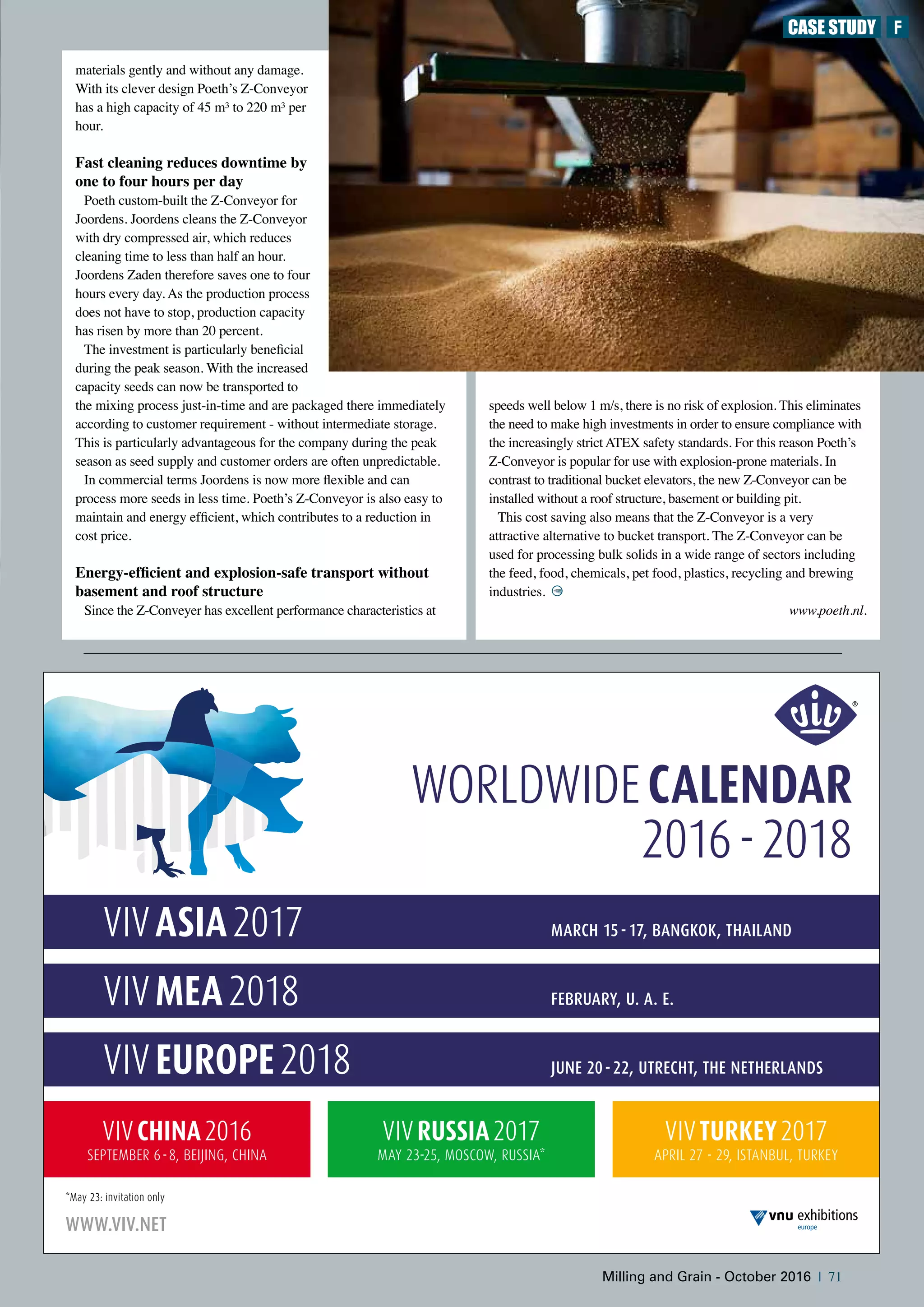

Joordens Zaden has enhanced its production capacity by over 20% with the installation of Poeth's Z-conveyor, which is capable of transporting a minimum of 75 m3 of fragile seeds to heights of eight meters, ensuring gentle and damage-free handling. The new conveyor system is designed for easy cleaning, reducing downtime to less than half an hour, unlike the previously used screw conveyor that took up to 1.5 hours. This improvement allows Joordens to operate more flexibly during peak seasons, meeting customer demands more efficiently while maintaining high quality standards.