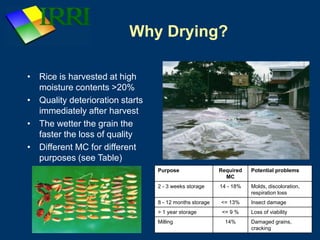

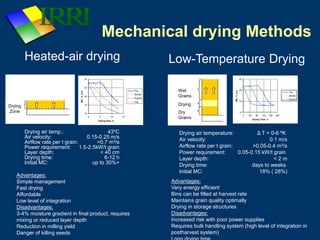

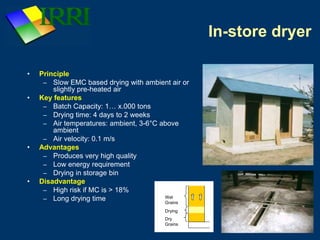

This document discusses various methods for drying paddy rice after harvest. It begins by explaining why drying is important to prevent quality deterioration and allow for longer term storage. Improper drying can lead to mold, discoloration, and reduced milling yields. Traditional drying methods like sun, panicle, and mat drying are described along with their disadvantages. Mechanical drying systems like batch, continuous flow dryers and low-temperature drying are presented in more detail. Key parameters for drying like air temperature, velocity and moisture gradients are outlined. Drying strategies involving on-farm, centralized and two-stage drying are proposed to optimize quality and efficiency.