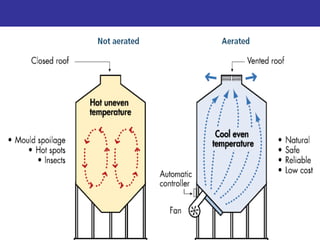

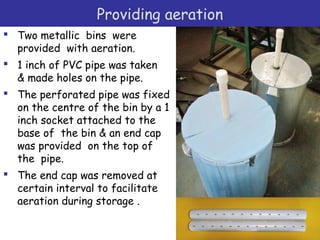

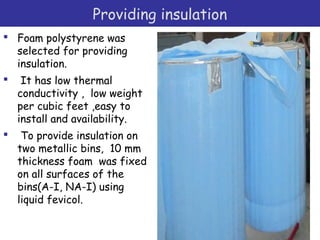

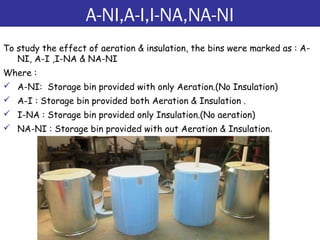

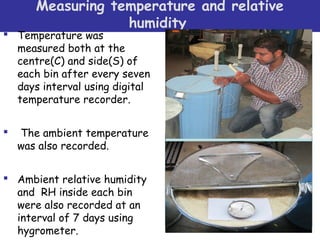

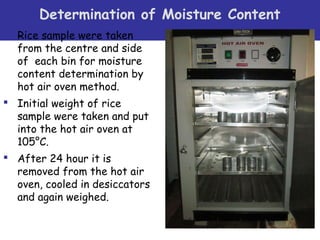

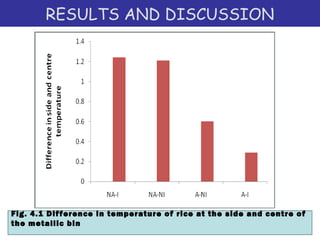

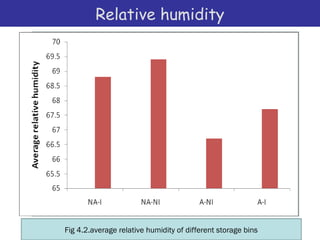

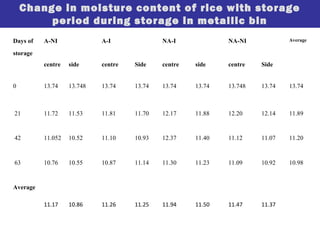

This document summarizes a study on storing rice in metallic bins. The study tested the effects of insulation and aeration on temperature, moisture content, and insect infestation. Four bins were used - two with aeration, two with insulation, and combinations of the two. Results showed that aeration helped maintain uniform temperature inside bins and lowered relative humidity compared to non-aerated bins. After 63 days, moisture content decreased similarly across all bins. No insect infestation occurred. The study concluded that aeration can successfully manage rice storage temperatures and properties while preventing losses from insects.