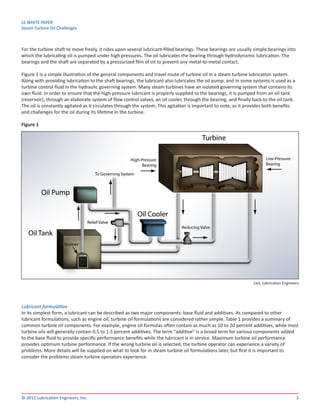

This document discusses challenges with steam turbine lubrication, focusing on varnish formation. It describes how steam turbines work to convert rotational energy from steam into electricity, with lubricant circulating through bearings to prevent metal-to-metal contact. Recent issues seen include entrained air and foam in the lubricant from agitation, loss of the lubricant's ability to separate water, and formation of sludge and varnish from degraded lubricant. The document suggests steam turbine operators can overcome these issues through a reliable lubrication program including proper lubricant selection and condition monitoring.