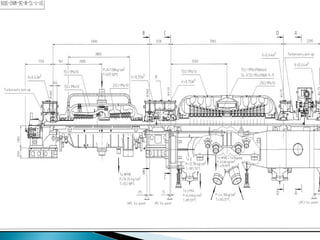

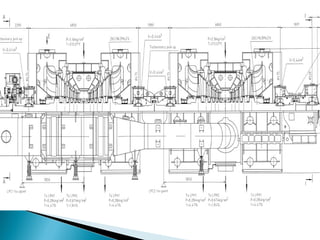

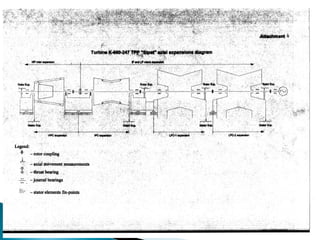

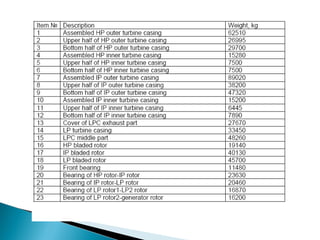

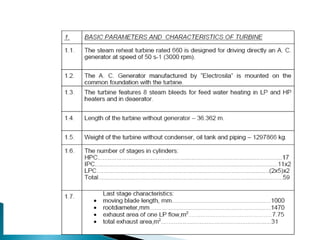

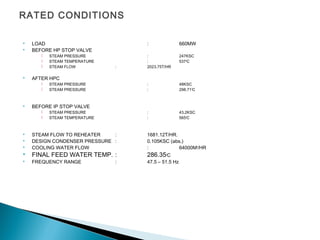

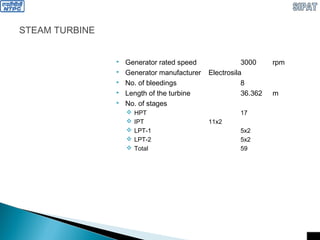

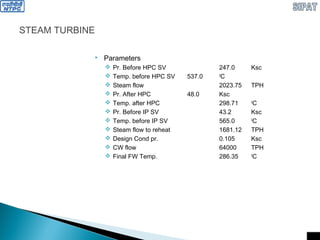

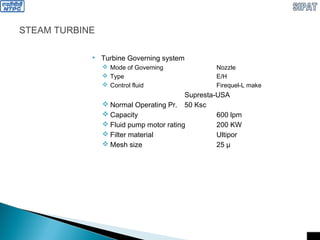

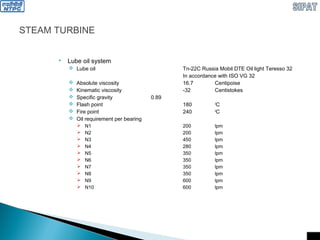

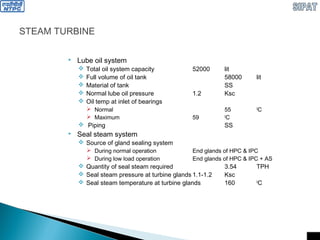

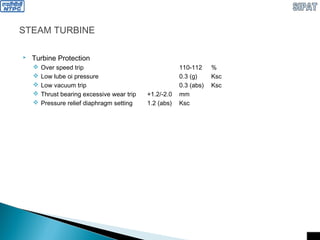

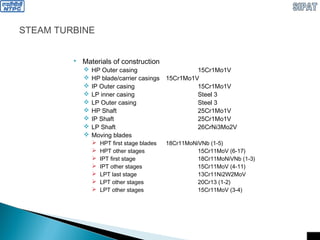

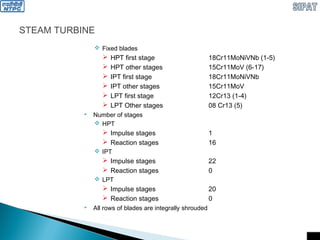

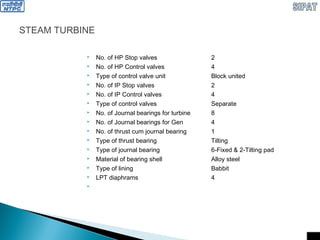

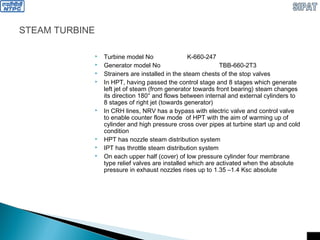

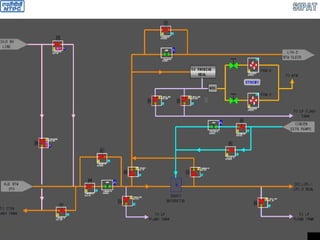

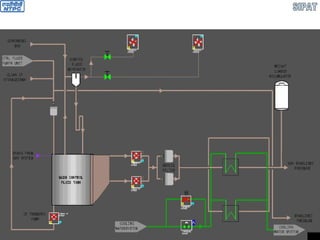

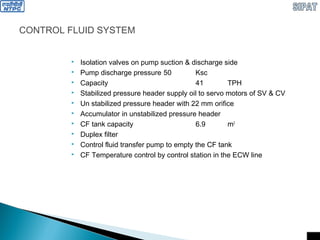

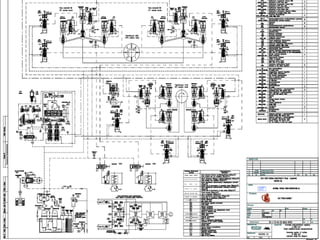

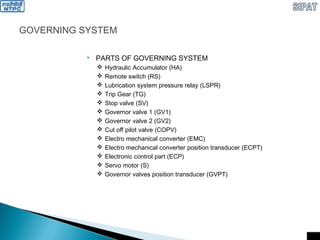

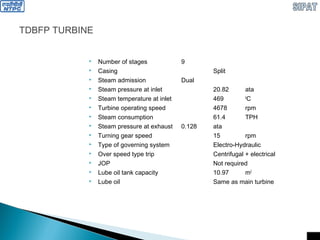

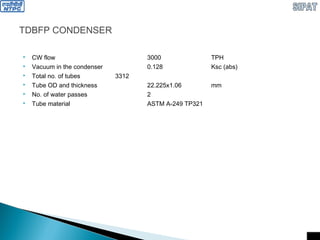

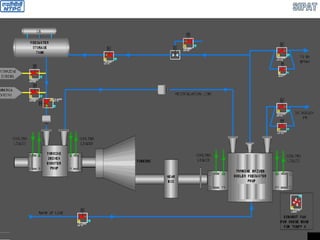

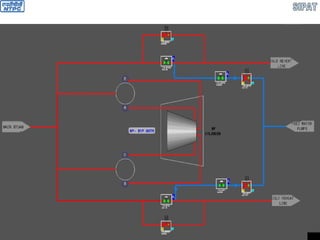

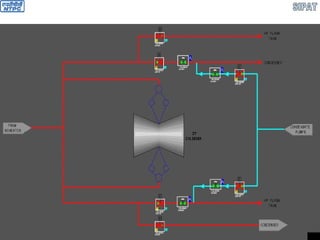

This document provides information about the 660MW turbo-generator and its associated systems for Stage-I of the Sipat Super Thermal Project. It summarizes key details about the steam turbine, its auxiliaries and rated operating conditions. The steam turbine is a K-660-247 model with 59 stages manufactured by LMZ. It operates at rated conditions of 660MW with steam pressure and temperature of 247KSC and 537°C respectively at the high pressure inlet. The document also outlines the turbine governing, lube oil, seal steam and control fluid systems along with specifications for materials, protections and auxiliaries.