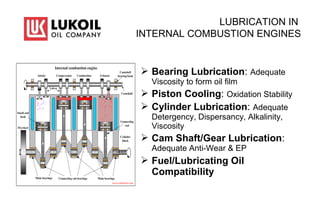

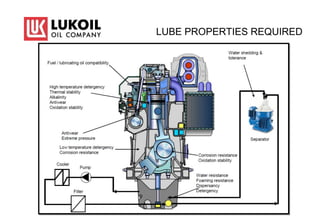

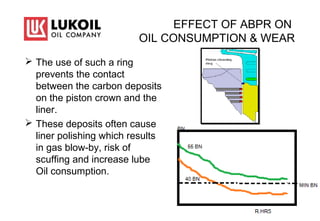

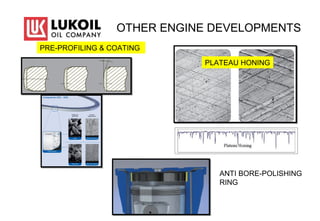

This document discusses lubrication of medium speed diesel engines. It covers topics like the properties required for lubrication in internal combustion engines including bearing lubrication, piston cooling, cylinder lubrication, and cam shaft/gear lubrication. It also discusses recent engine design trends that impact lubrication like higher combustion pressures and describes how this affects properties like viscosity and detergency needed in lubricating oils. The document provides an overview of used oil analysis and how it can help identify issues like ingression of fuel or combustion byproducts into the oil from sources like leakage. It provides an example analysis of engine #1 where rises in viscosity and drops in base number indicate likely fuel ingression that could be addressed by identifying and fixing the ingress source.