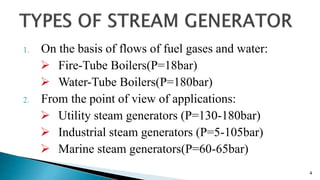

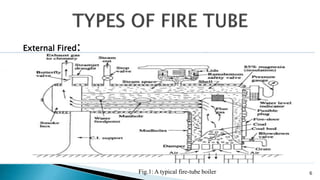

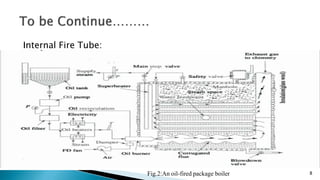

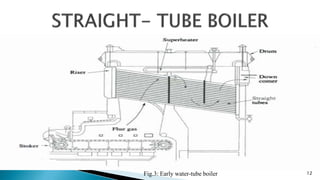

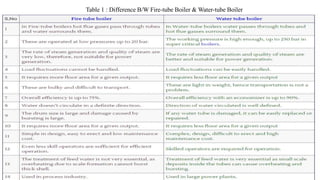

This document discusses fire-tube boilers and water-tube boilers. It begins by explaining that steam generators produce steam at desired rates and pressures by burning fuel in a furnace. It then describes that fire-tube boilers have combustion gases pass through tubes surrounded by water, while water-tube boilers have water pass through tubes with combustion gases on the outside. Key differences are that fire-tube boilers can only produce saturated steam up to 18 bars pressure, while water-tube boilers can reach much higher pressures and produce drier steam.