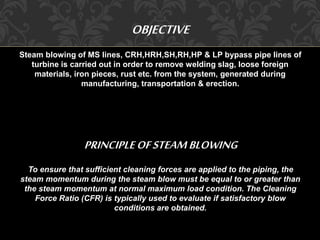

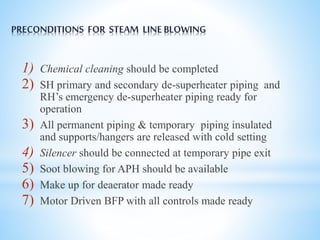

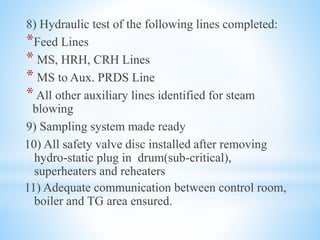

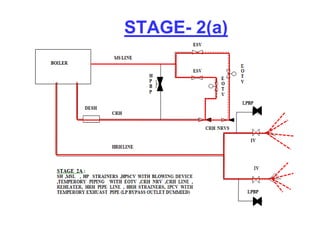

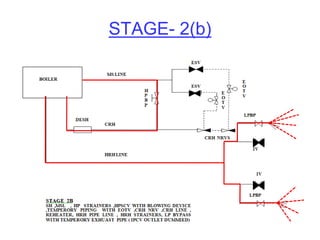

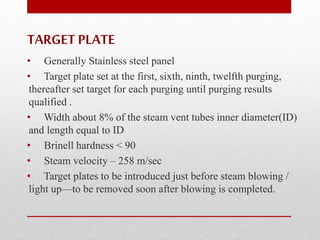

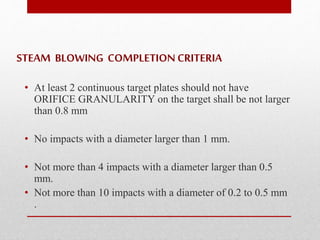

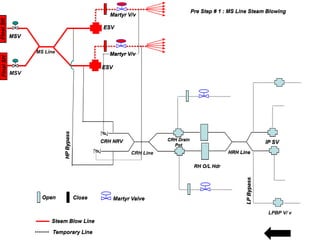

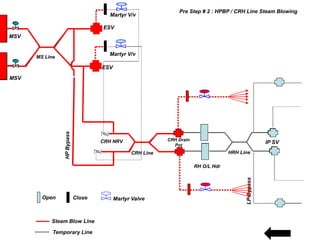

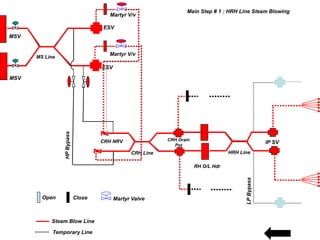

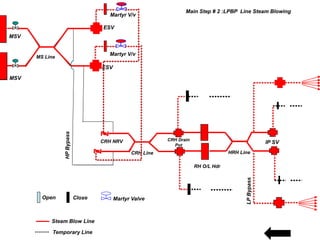

Steam blowing is carried out to remove welding slag, debris, and other foreign materials from turbine system piping generated during manufacturing and construction. It uses high velocity steam to purge lines through either puffing method, which uses thermal shocks, or continuous blowing method. The process is done in stages, with target plates used to evaluate cleanliness. The lines blown include steam, reheat, bypass, and other auxiliary lines. Blowing is completed when target plates show acceptable levels of debris indentation.