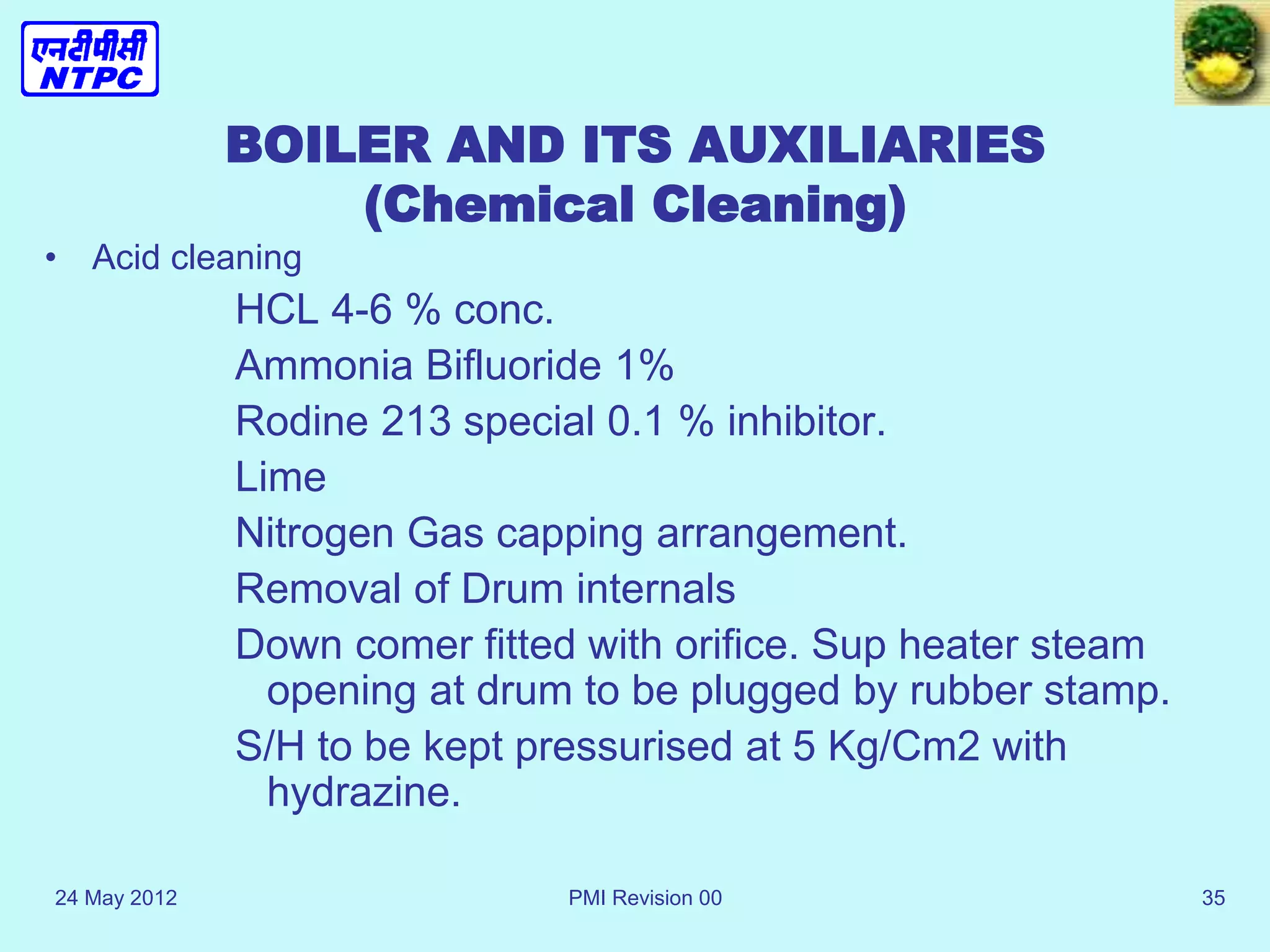

The document provides information on commissioning a boiler and its auxiliaries. It discusses various stages of commissioning including pre-commissioning checks, trial runs of equipment, hydraulic testing, chemical cleaning, gas tightness testing, ESP commissioning, fuel oil system checks, steam blowing, and other tests and procedures. The goal of commissioning is to ensure the boiler and associated systems operate safely and reliably according to design specifications before full operation.