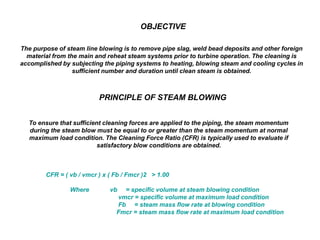

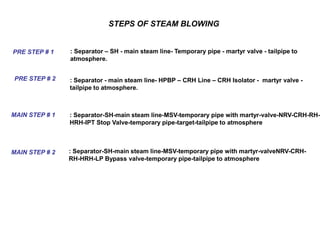

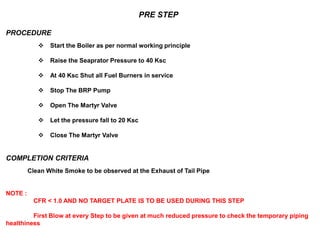

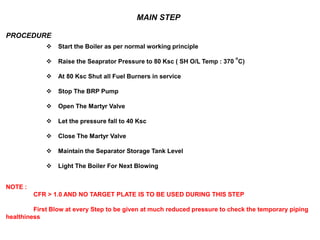

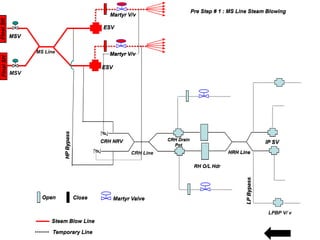

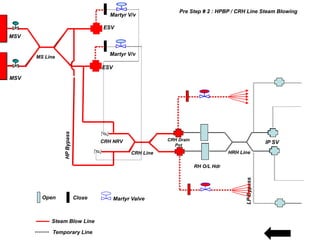

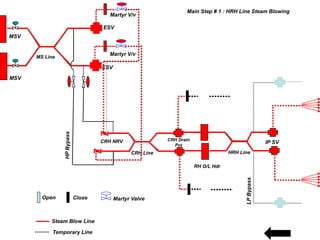

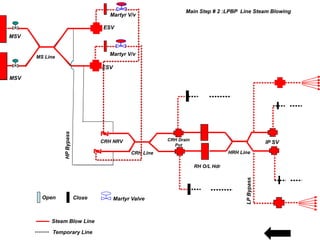

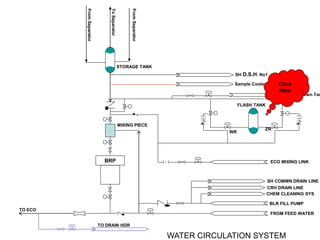

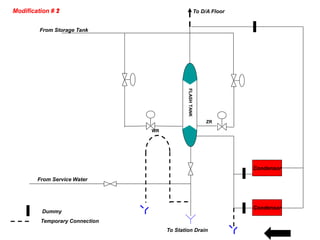

The document outlines the purpose and procedures for steam blowing, which aims to cleanse steam piping systems of contaminants before turbine operation. It details the steps involved in both pre and main steam blowing, including criteria for completion and specific operational procedures. The document also discusses the cleaning force ratio (CFR) used to evaluate the effectiveness of the blowing process.