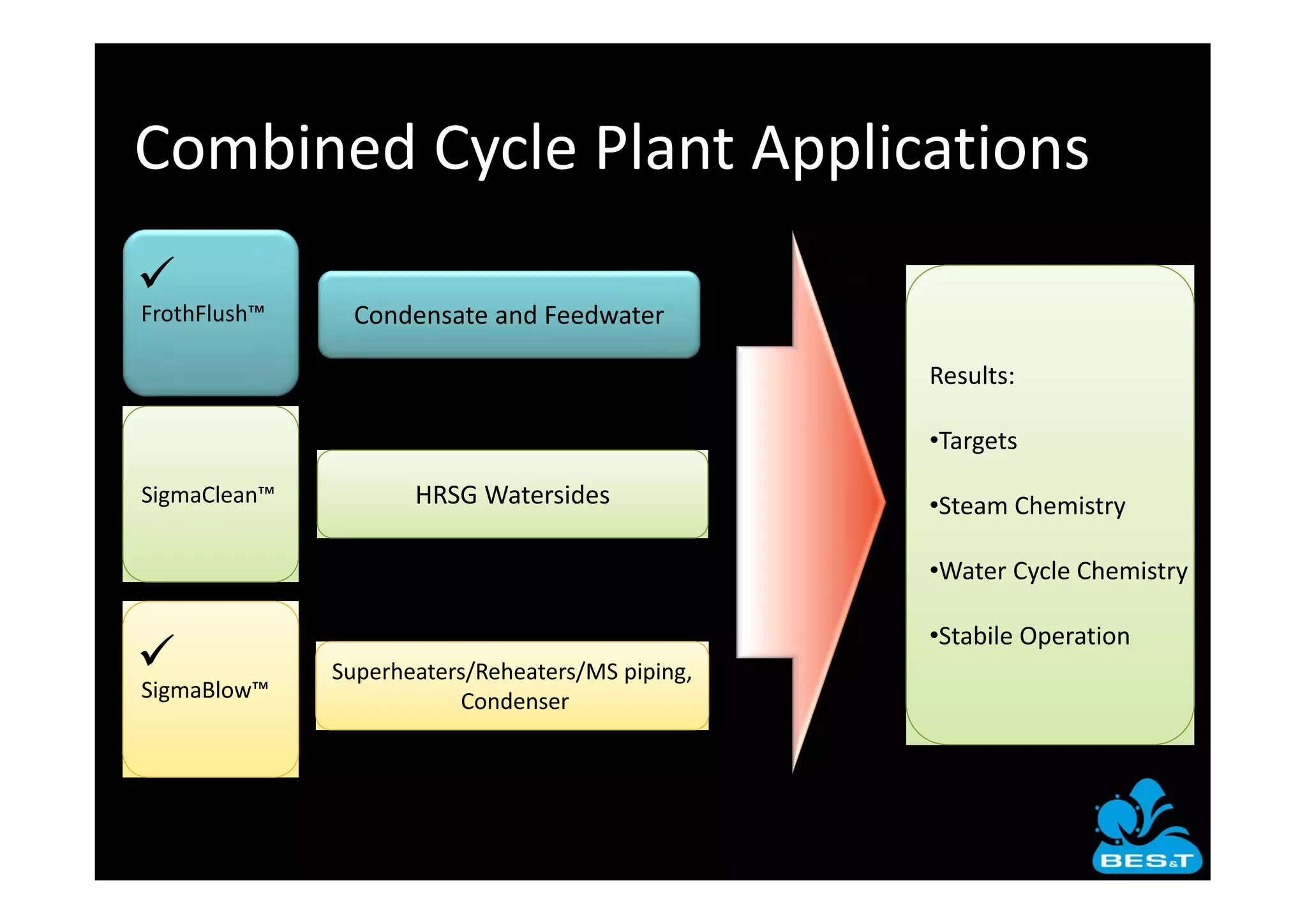

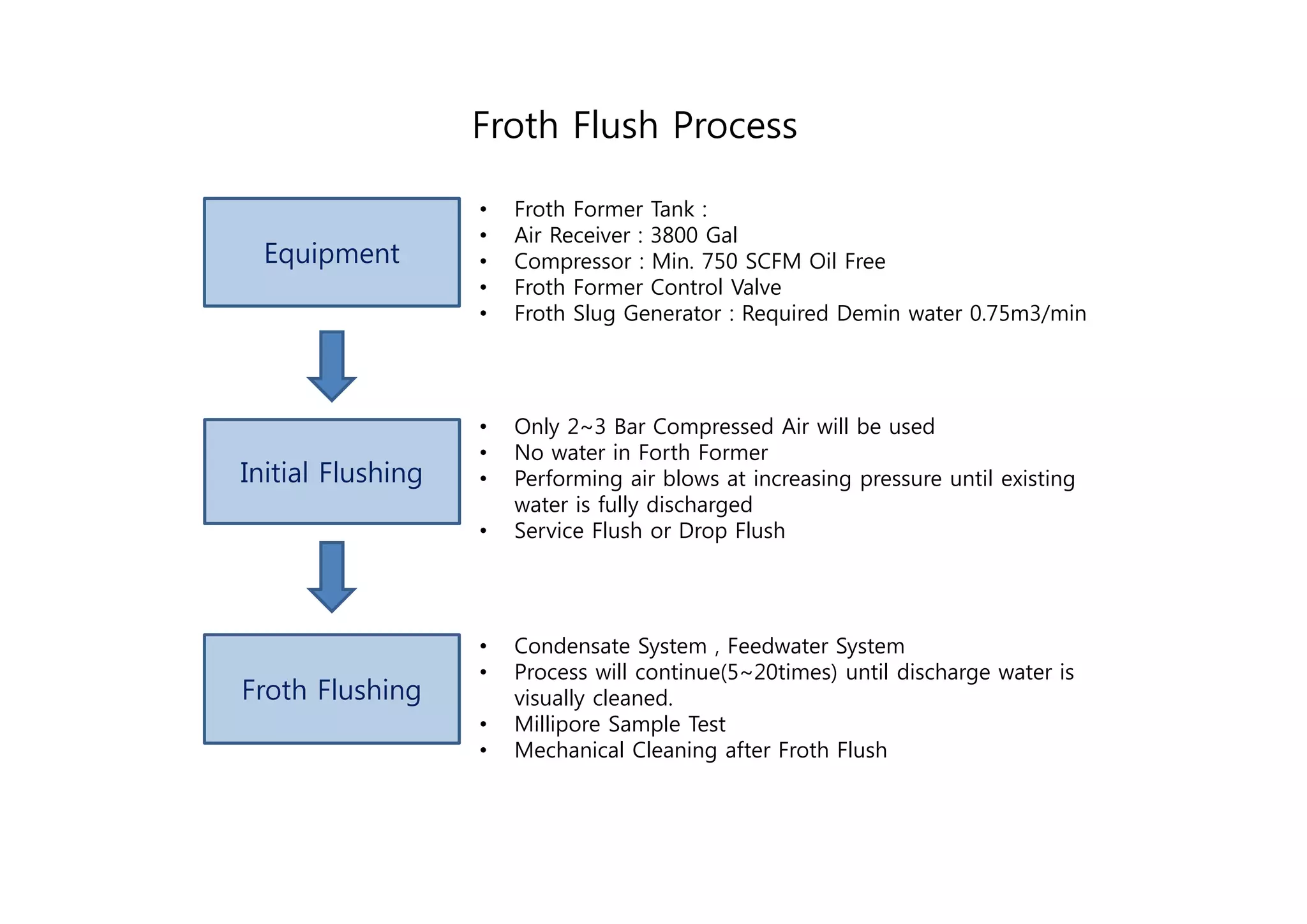

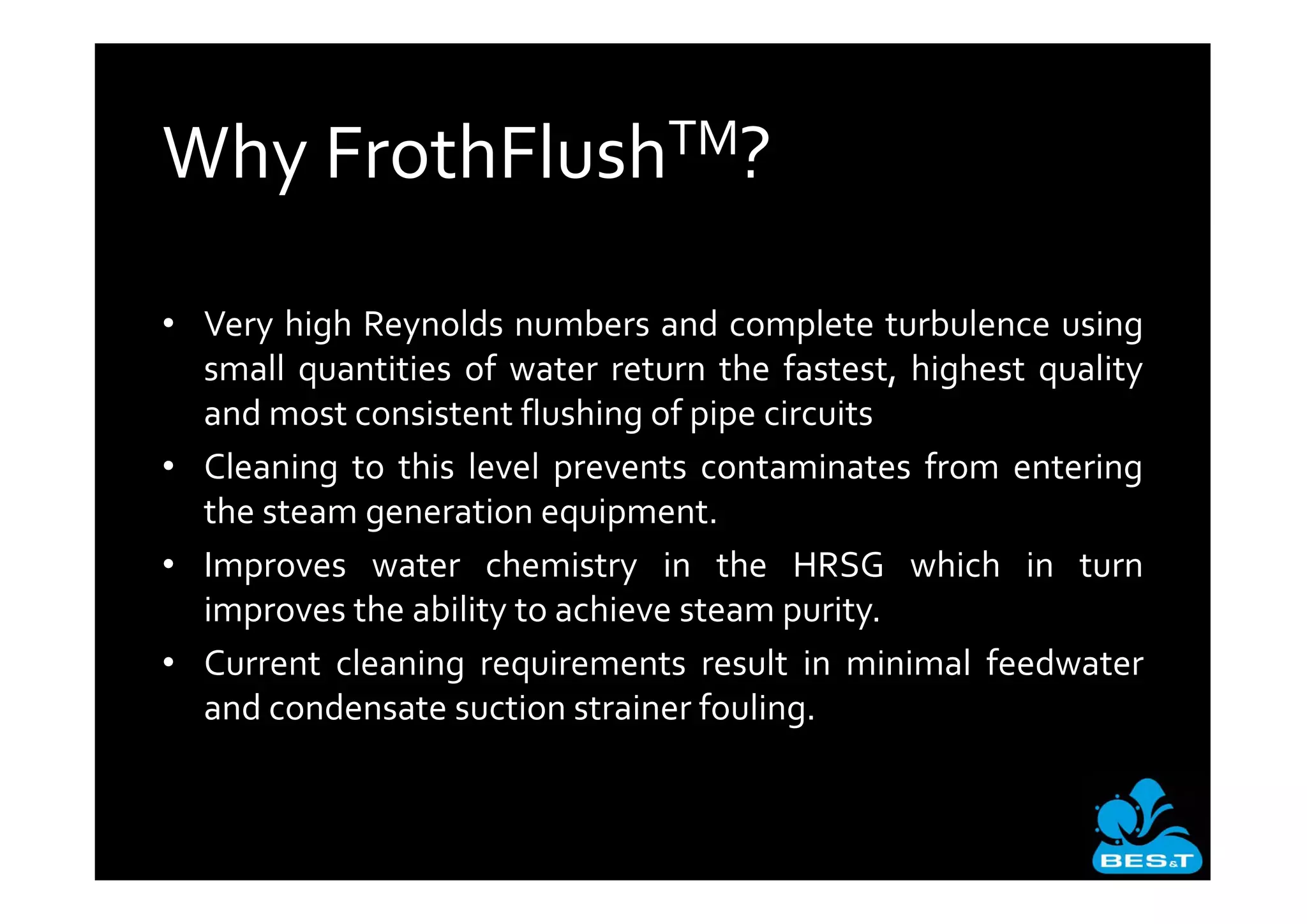

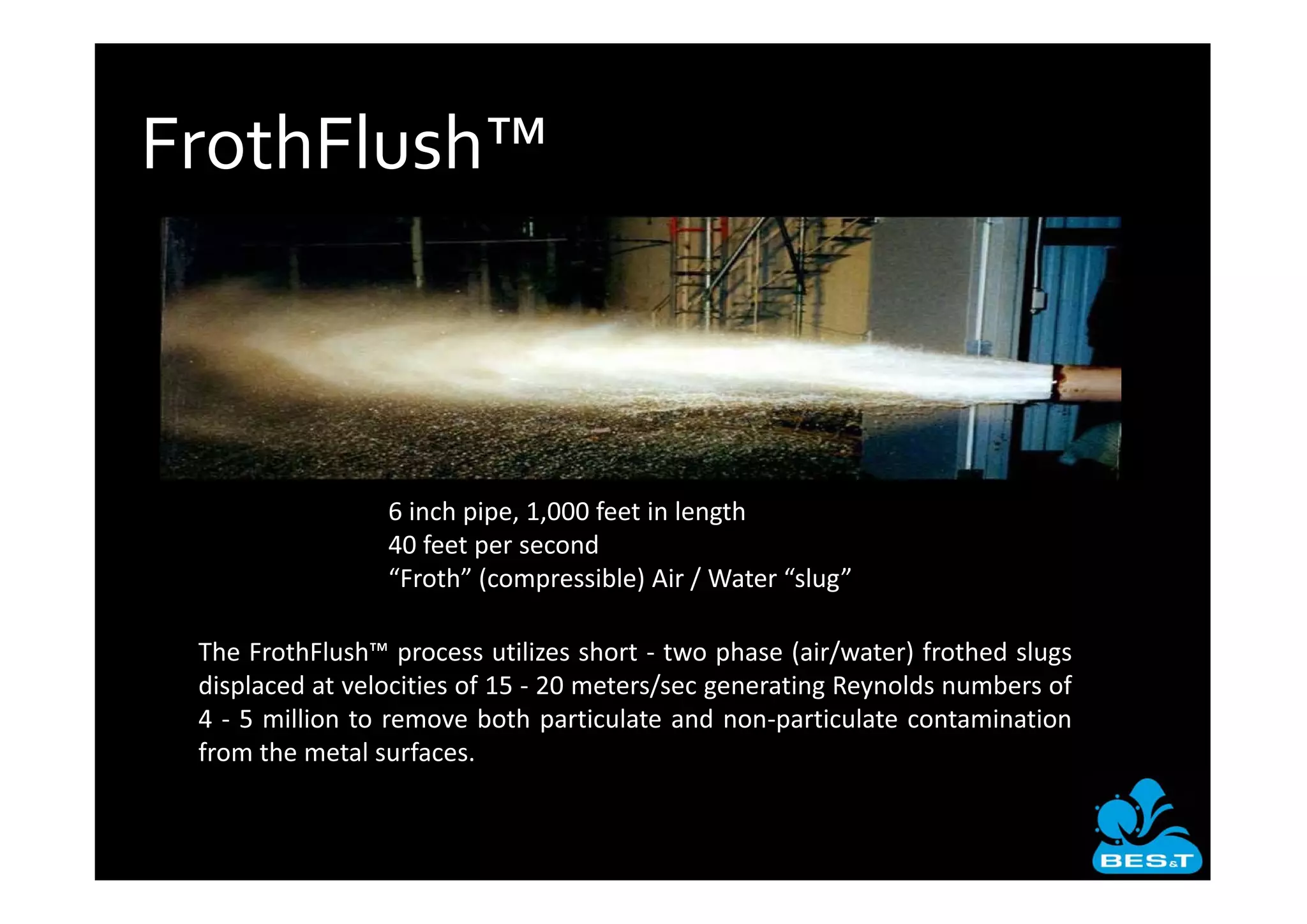

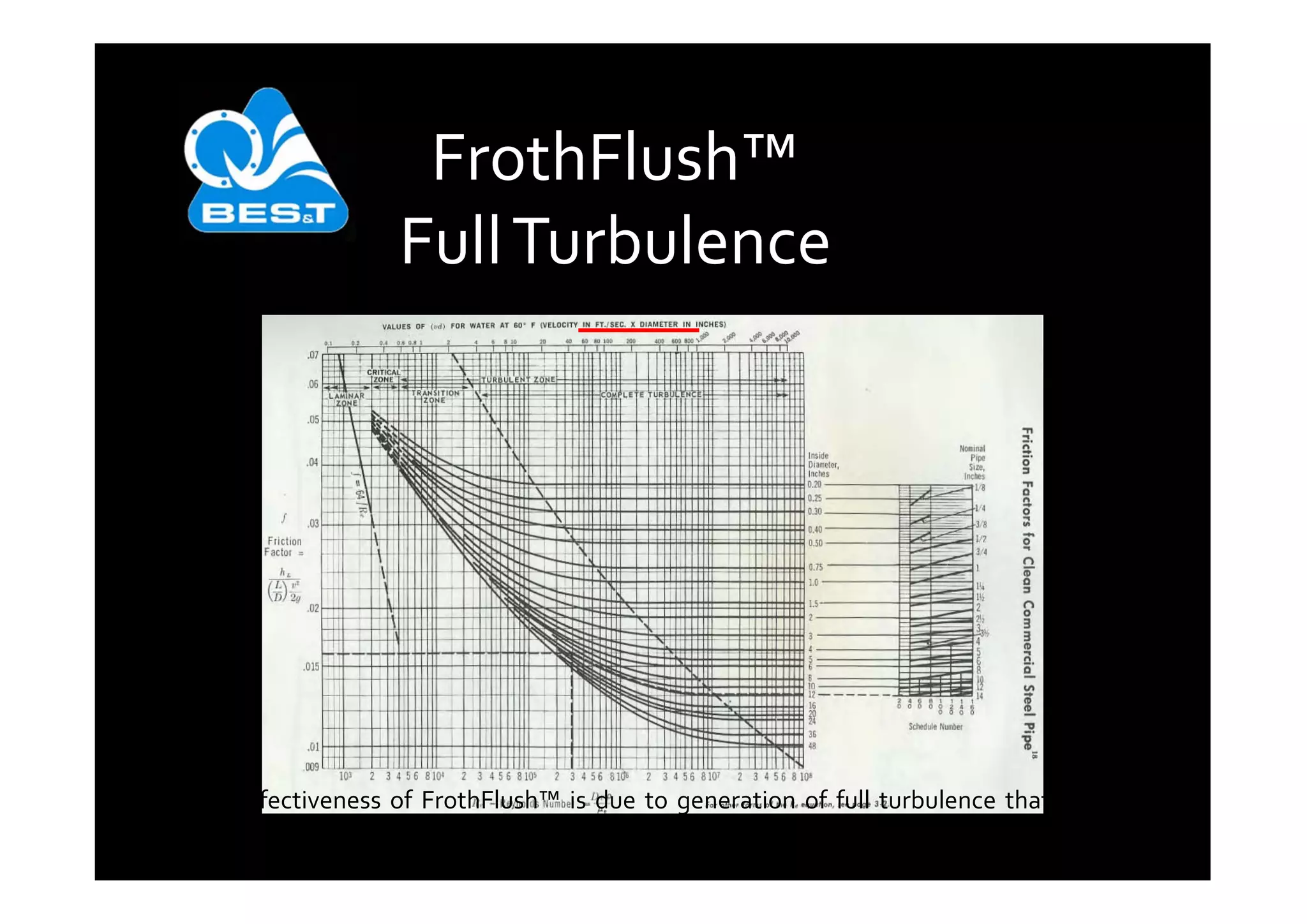

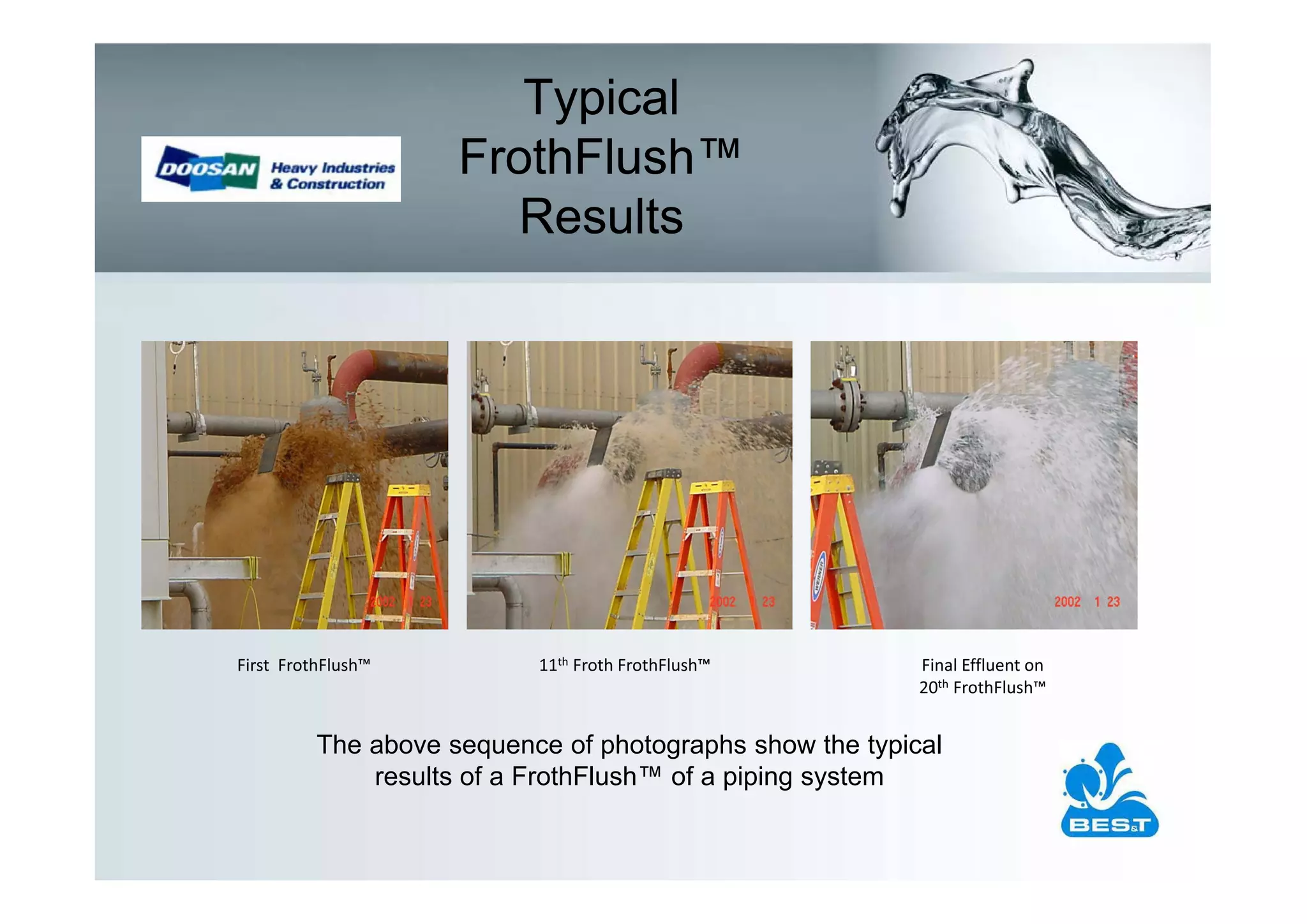

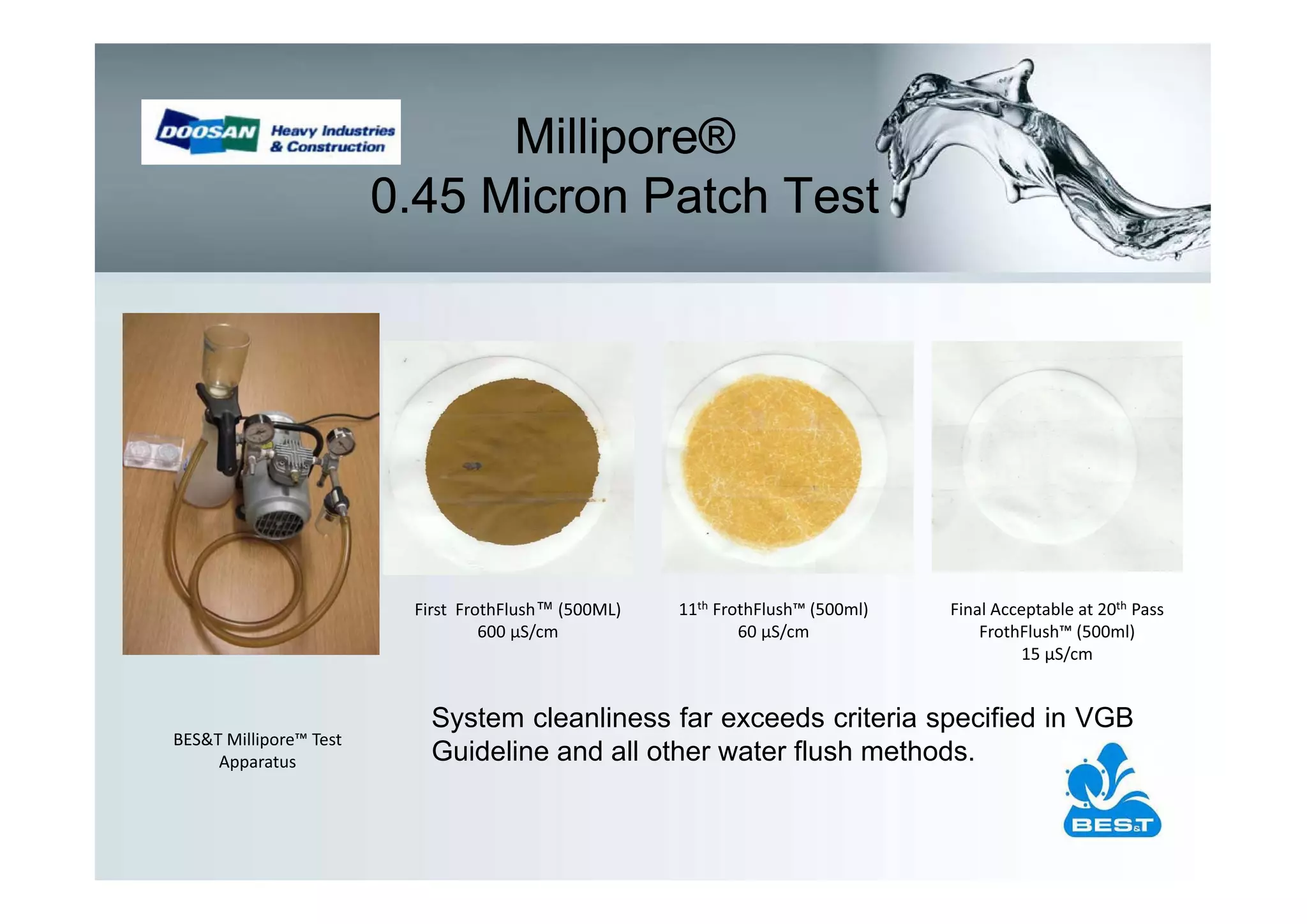

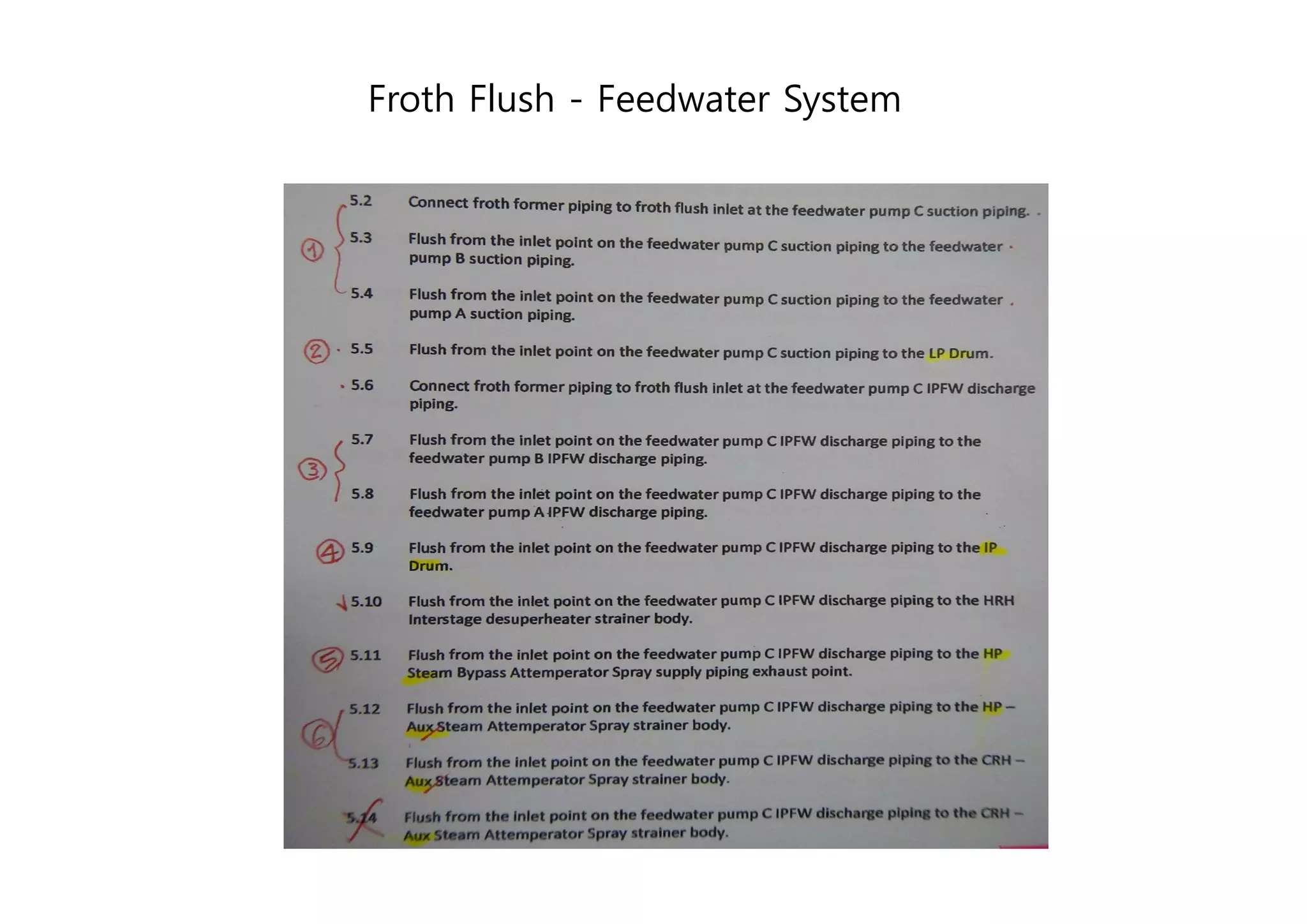

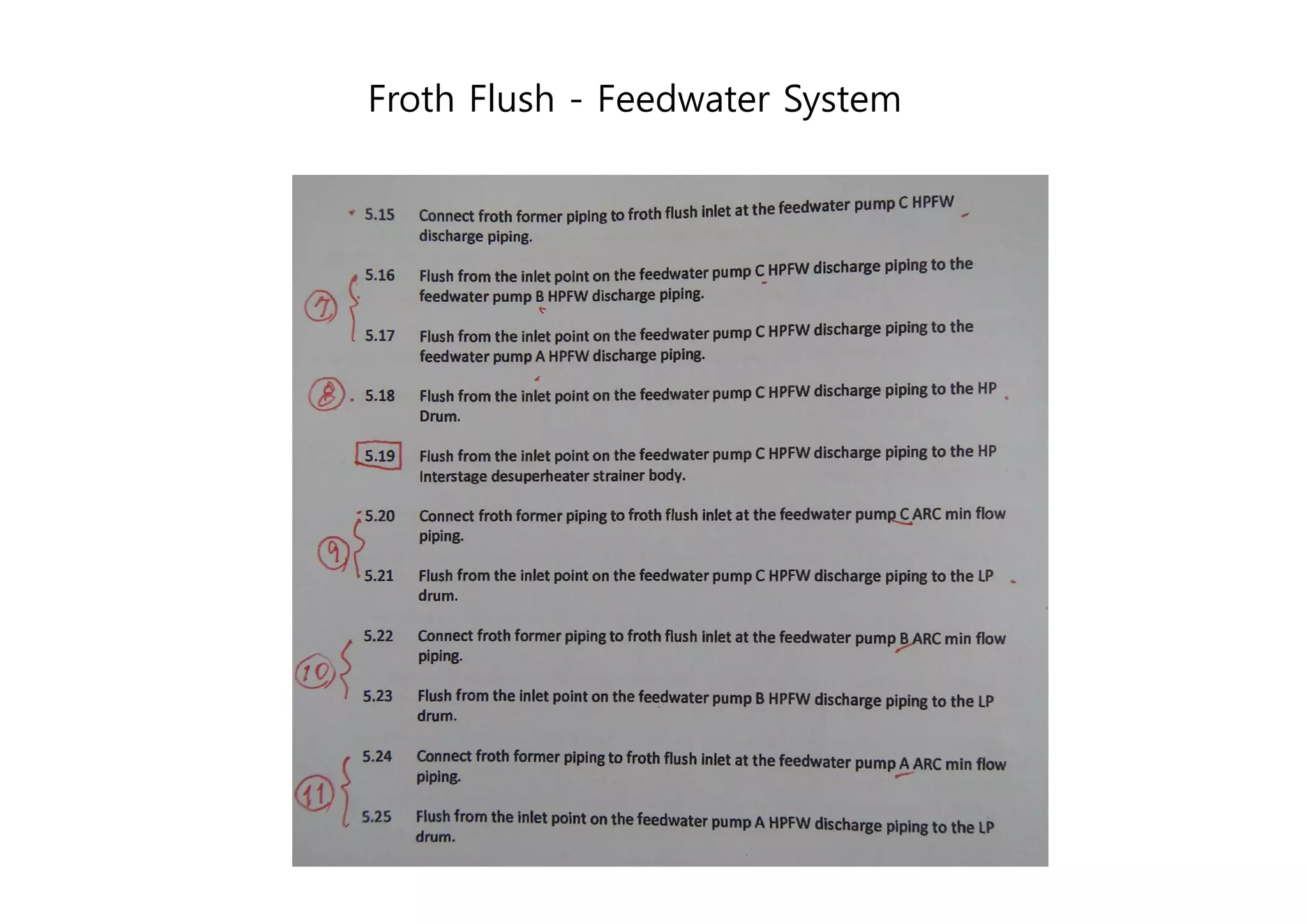

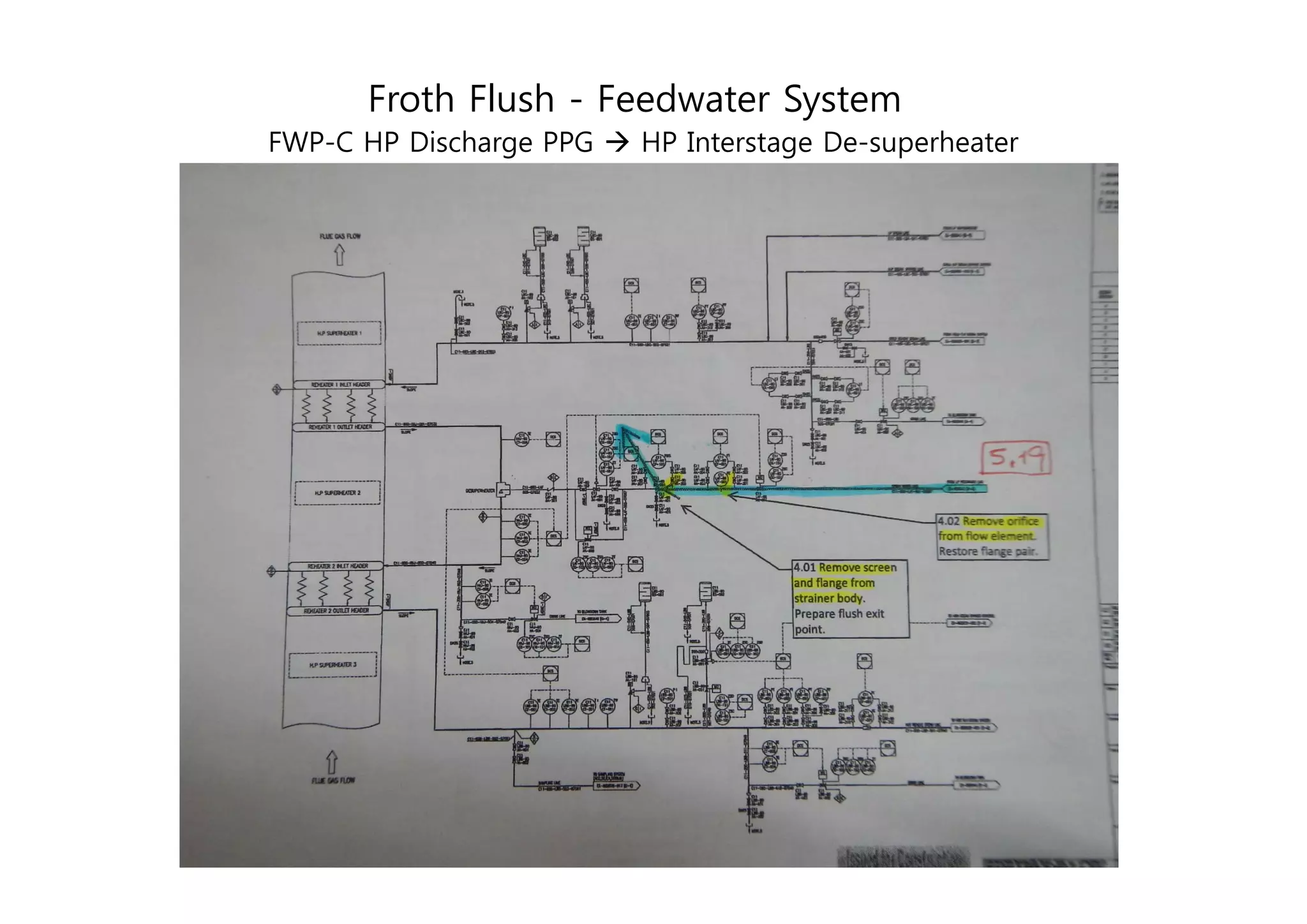

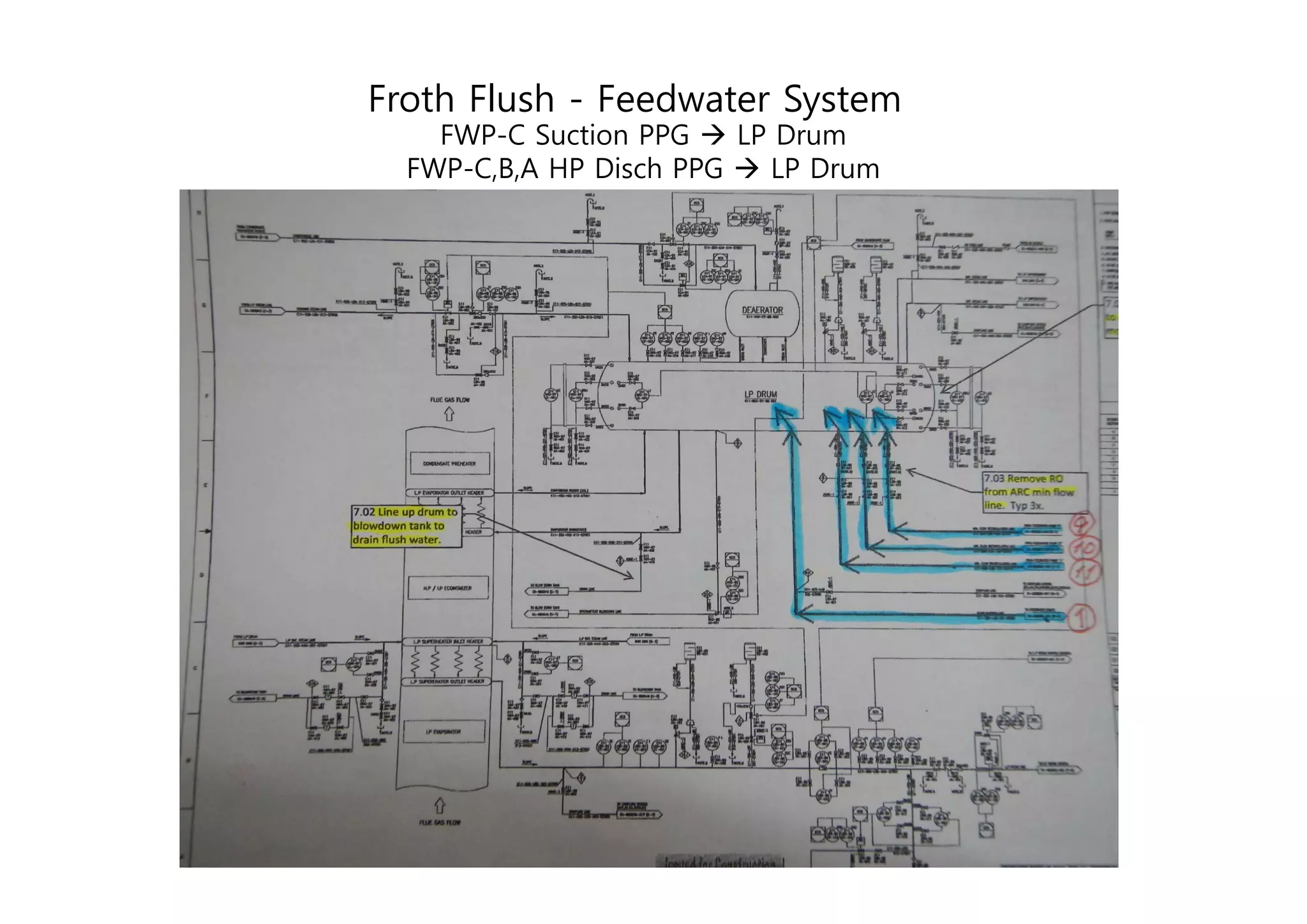

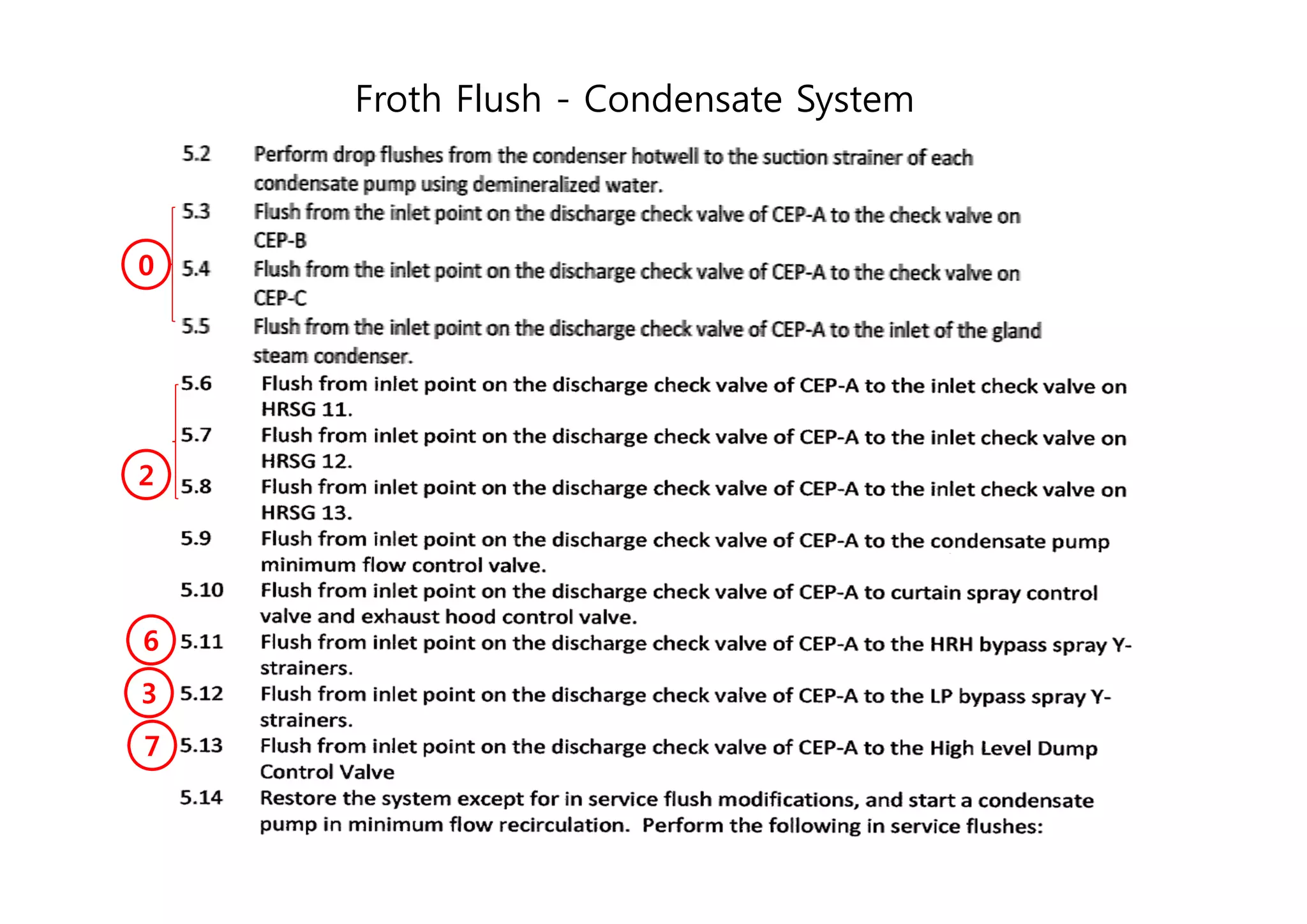

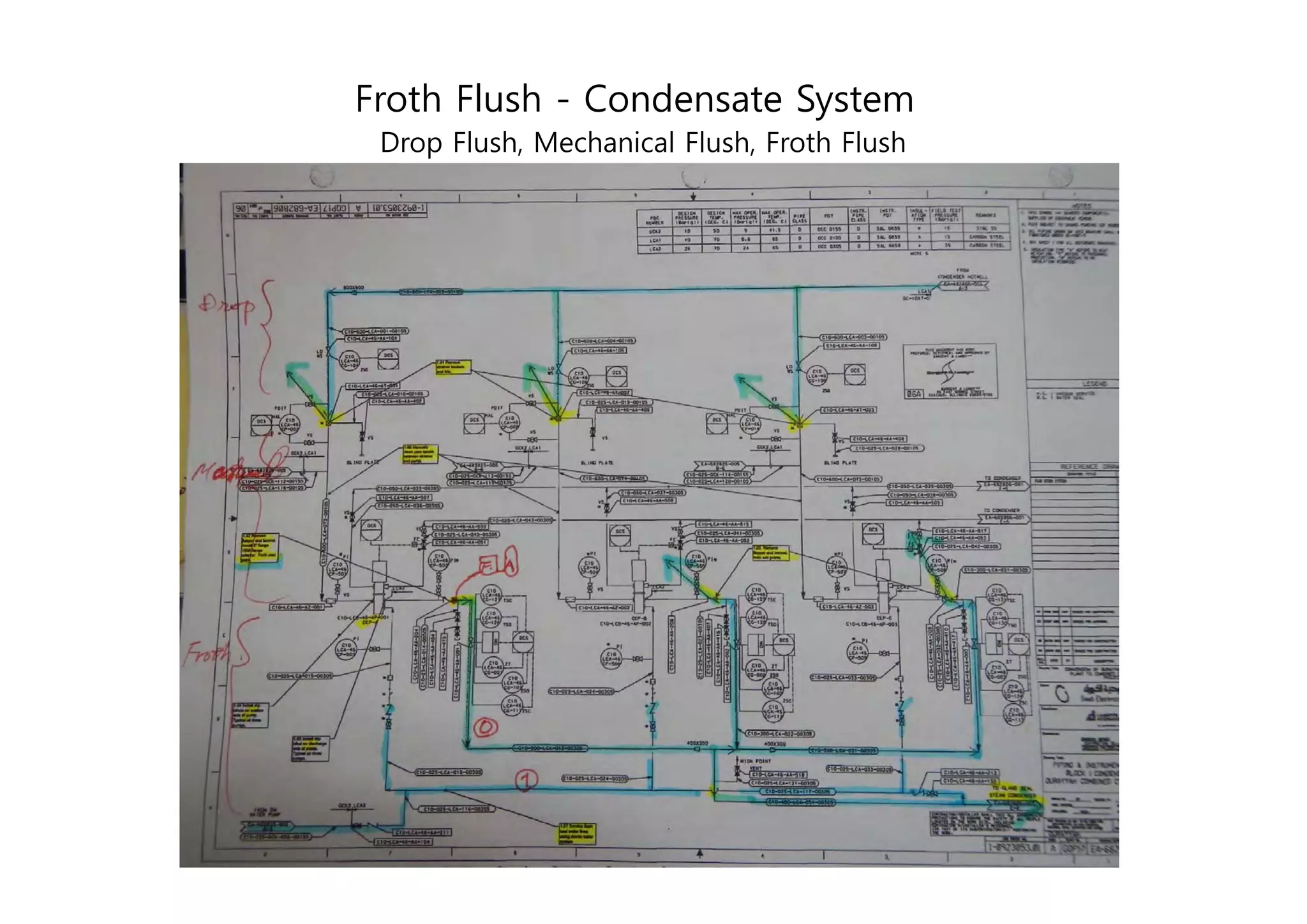

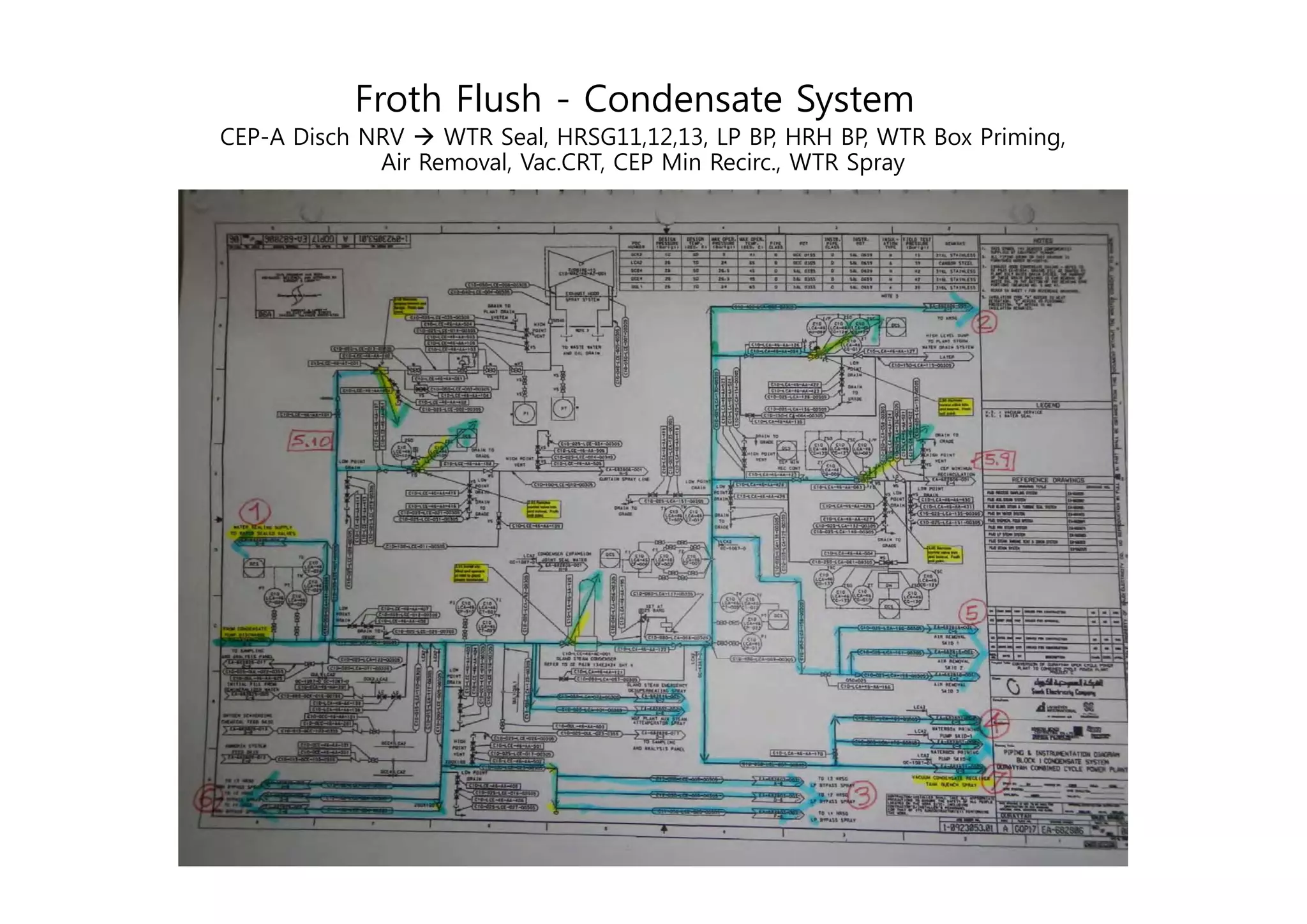

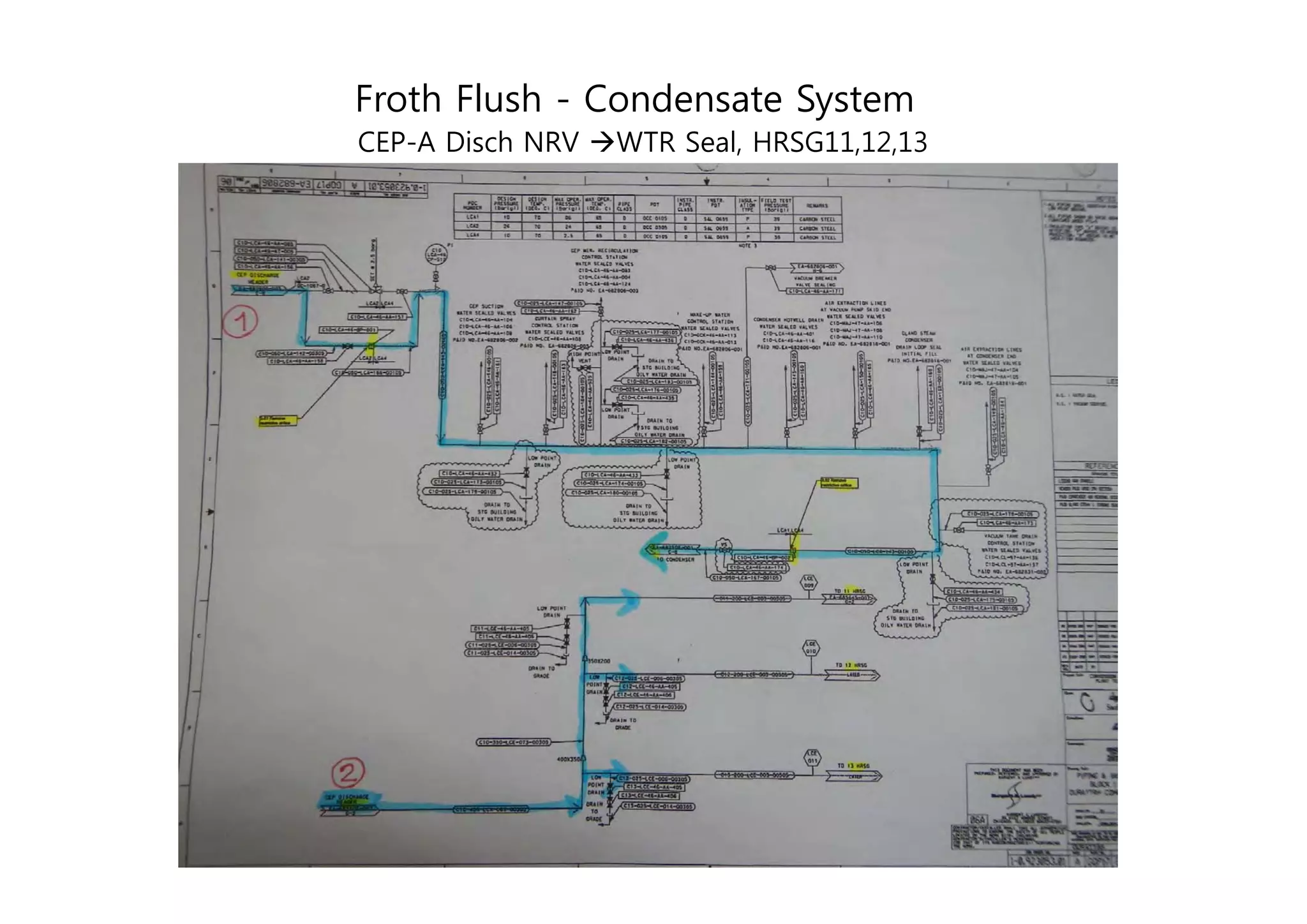

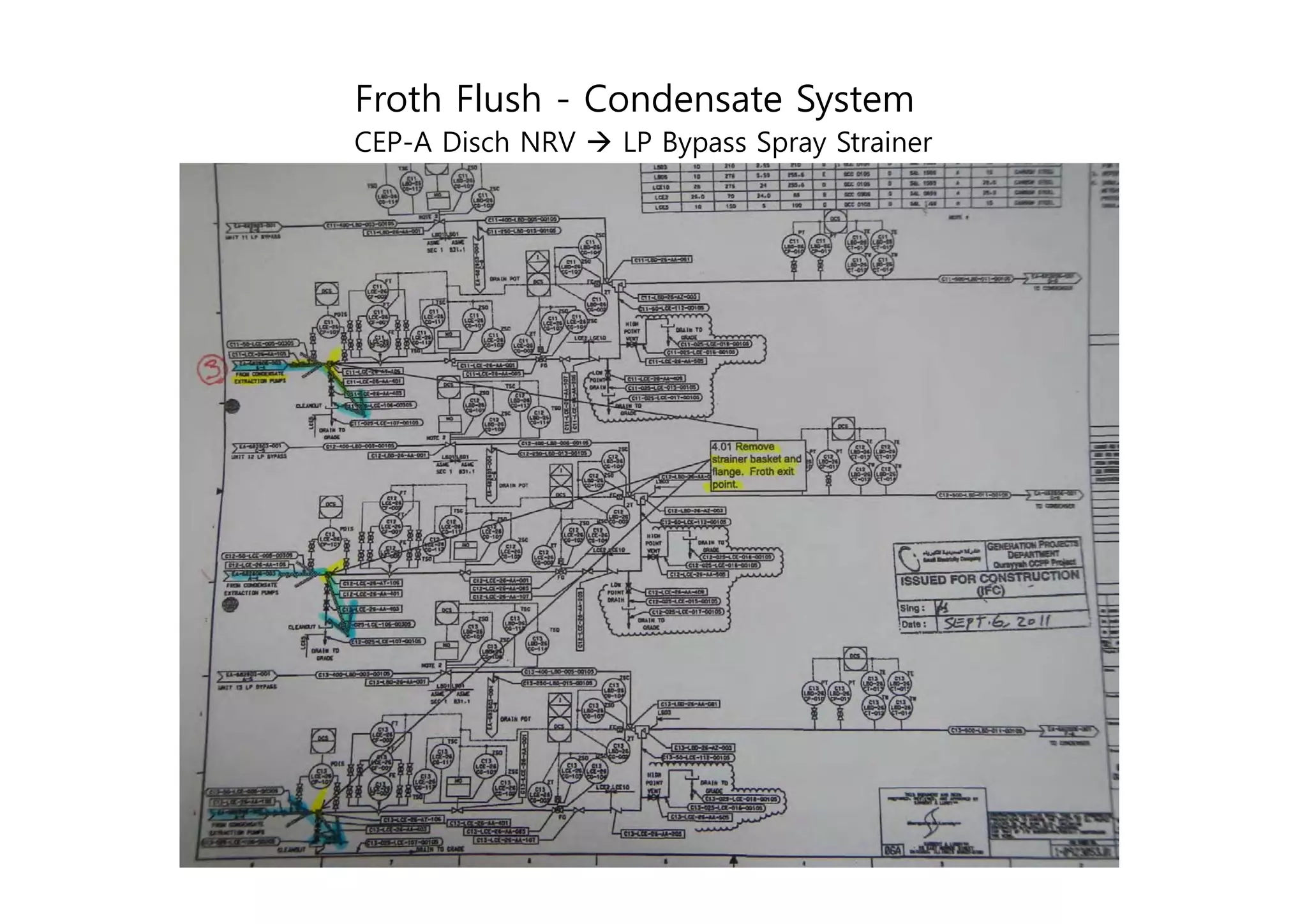

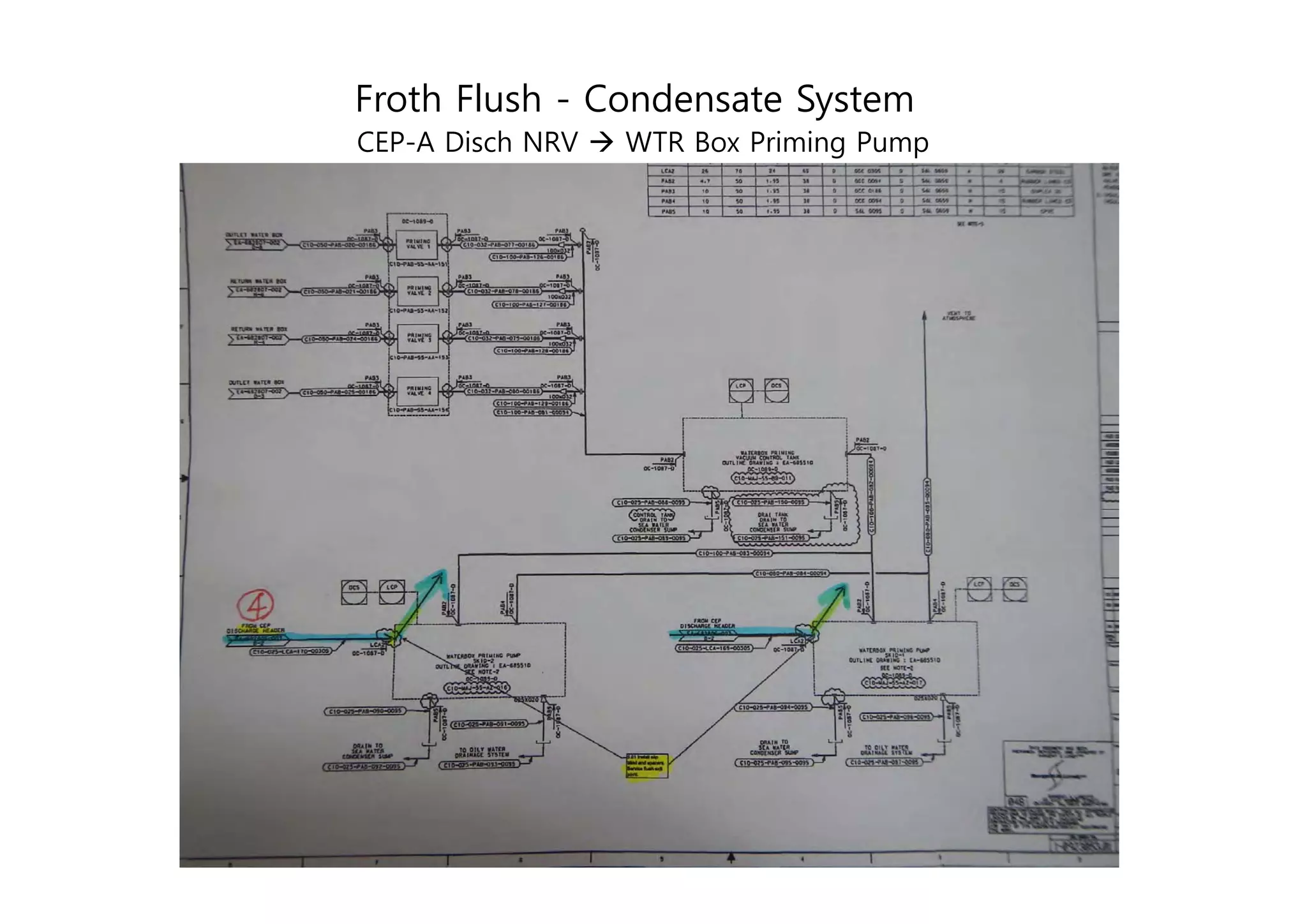

The document discusses the FrothFlushTM process for cleaning combined cycle plant components such as condensate lines, HRSG watersides, superheaters, reheaters, and condensers. It explains that FrothFlushTM uses high velocity slugs of compressed air and water to generate full turbulence that scrubs surfaces, removing particles and salts. Test results show FrothFlushTM achieves much cleaner results than other methods, with conductivity below 50 uS/cm and solids below 0.05 mg/L. FrothFlushTM is also effective for cleaning preheat and economizer coils in HRSGs.