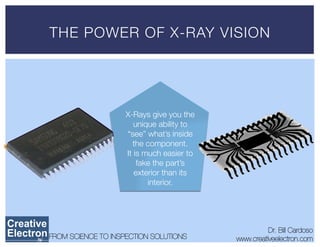

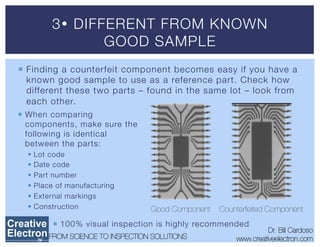

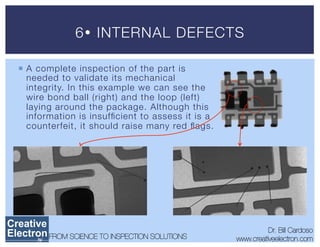

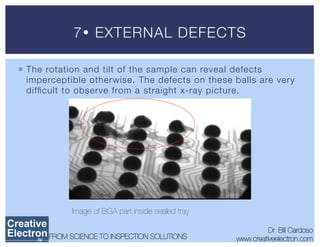

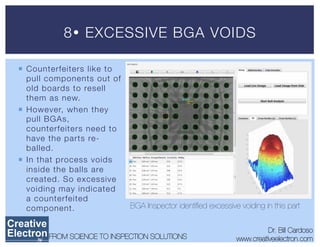

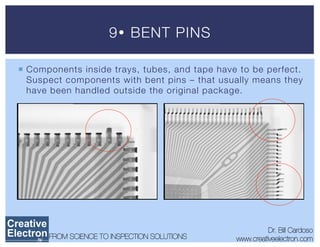

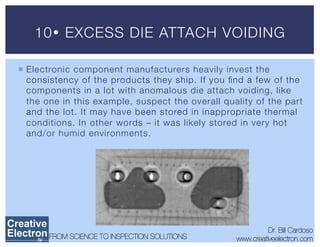

The document outlines ten methods for detecting counterfeit electronic components utilizing x-ray technology. It emphasizes the importance of thorough inspections, comparing components to known good samples, and identifying unique signatures such as internal features and manufacturing inconsistencies. Creative Electron offers solutions and expertise in quality inspection, including automated systems for counterfeit detection.