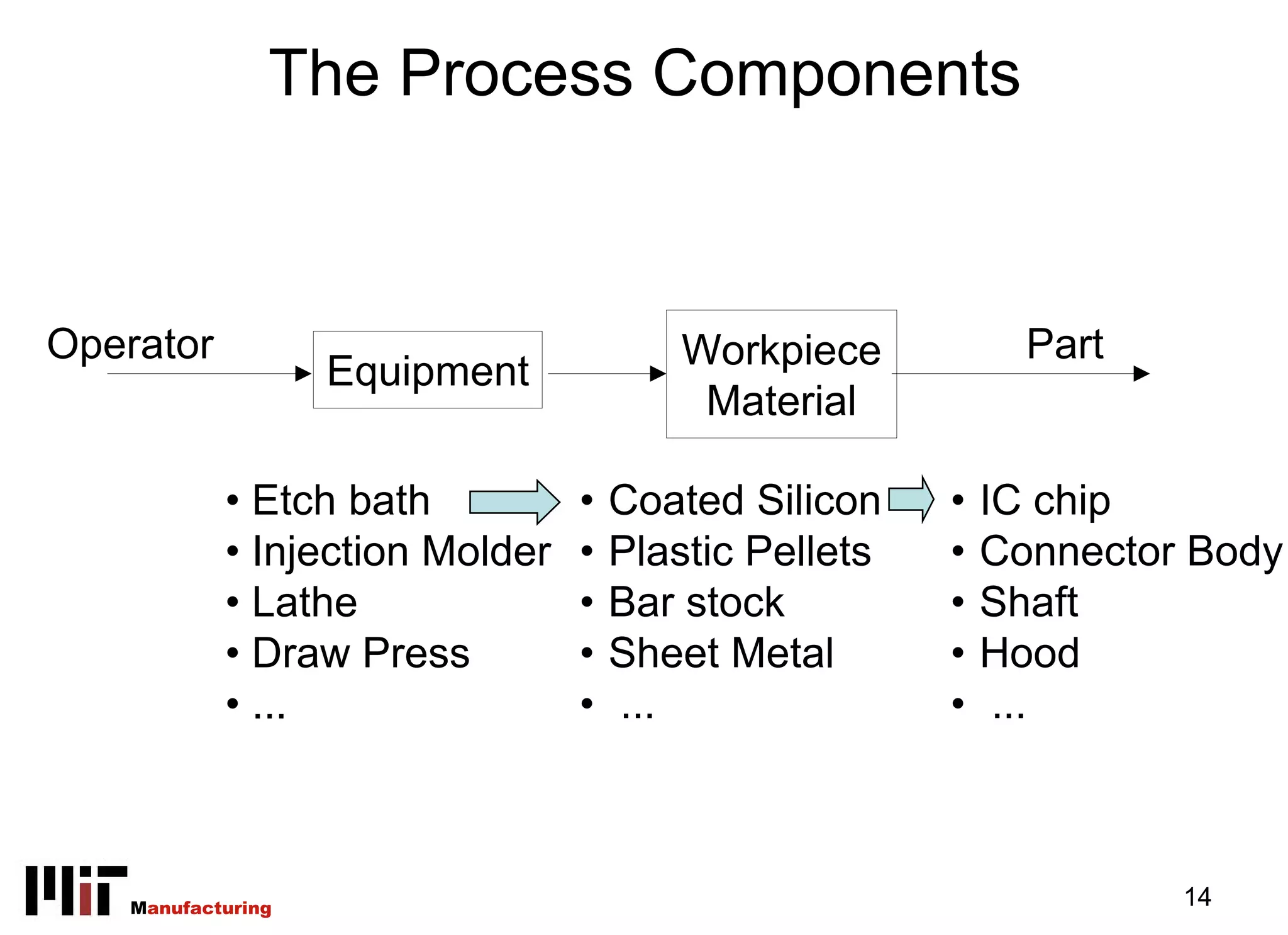

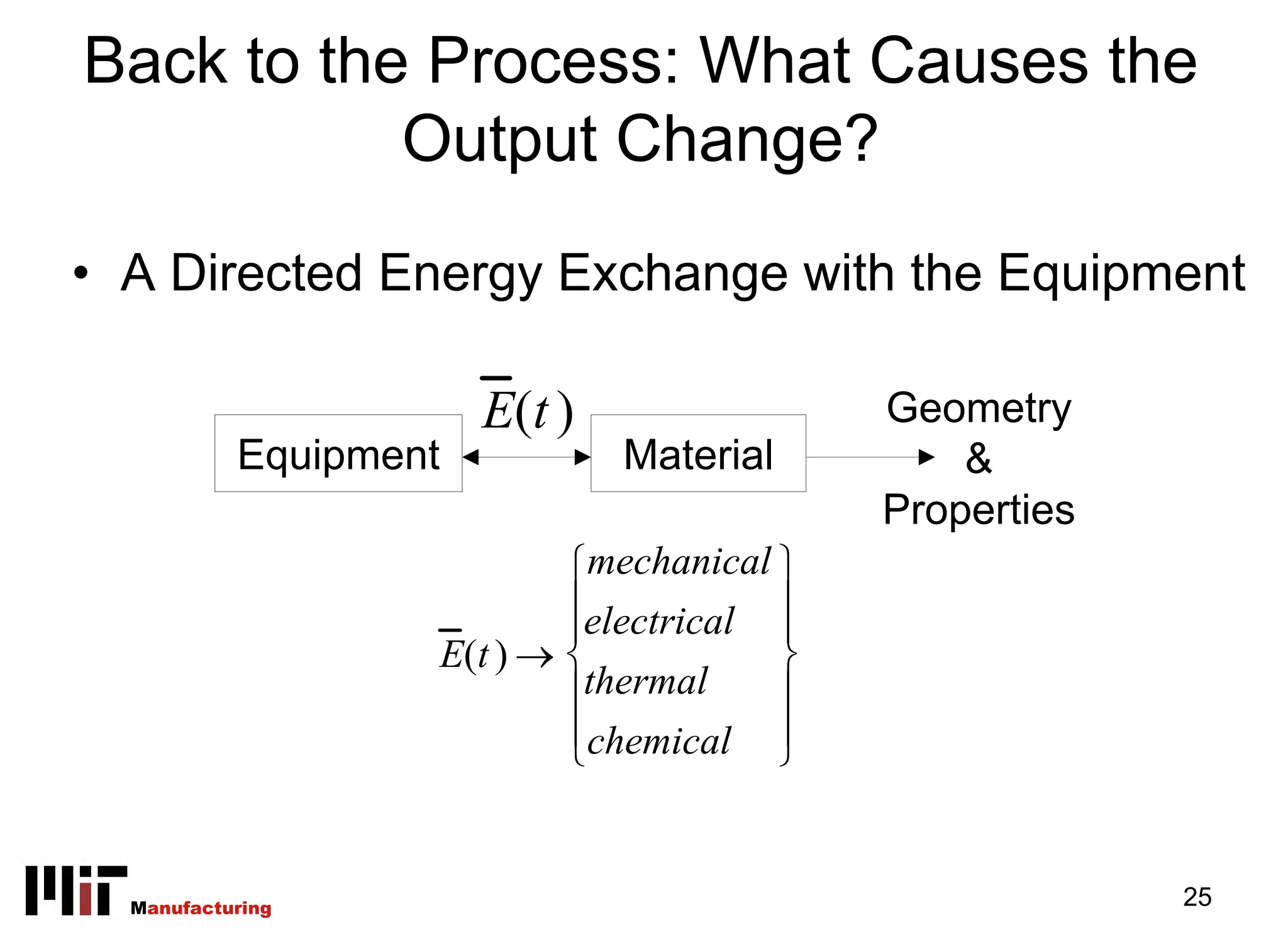

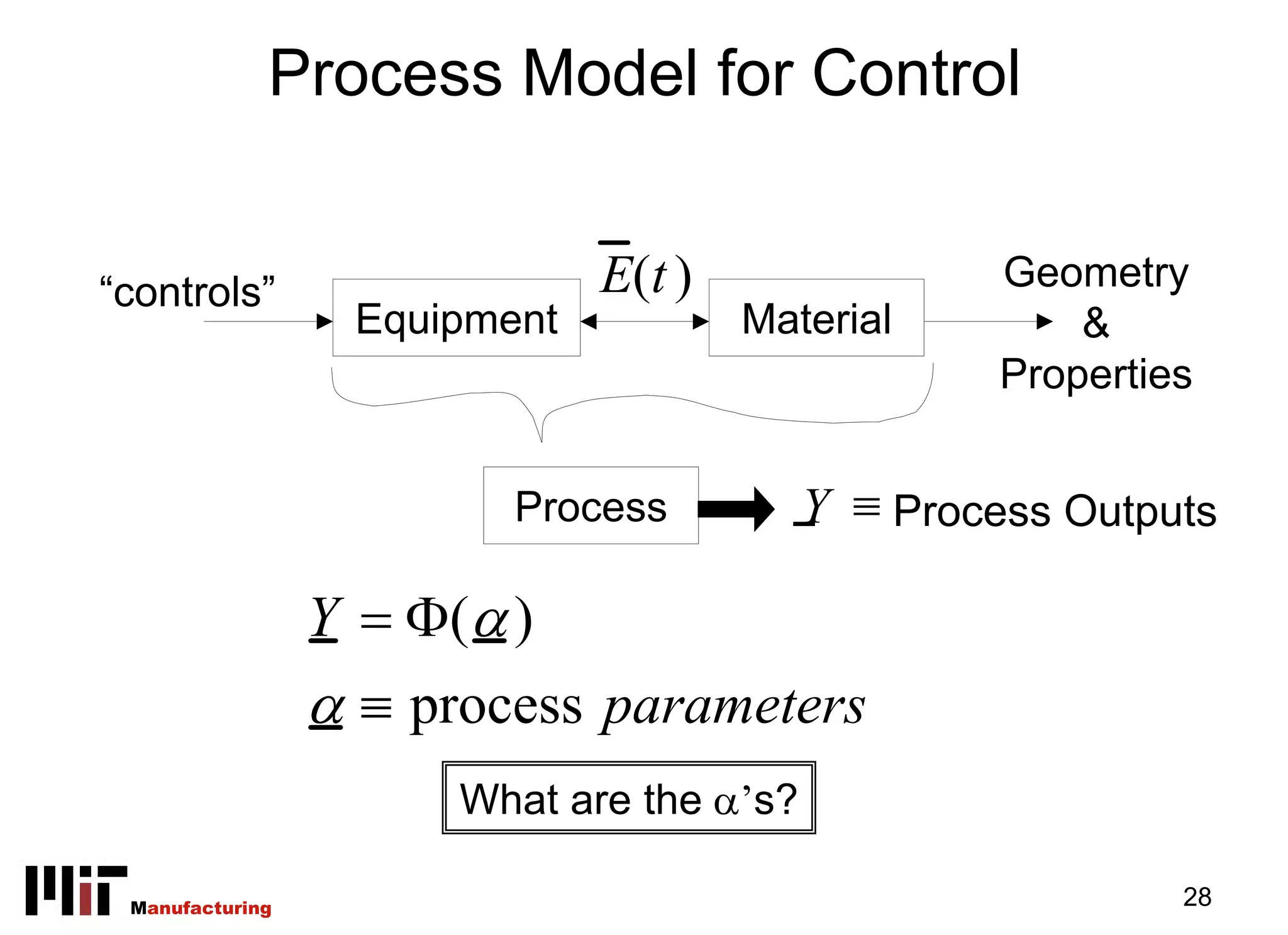

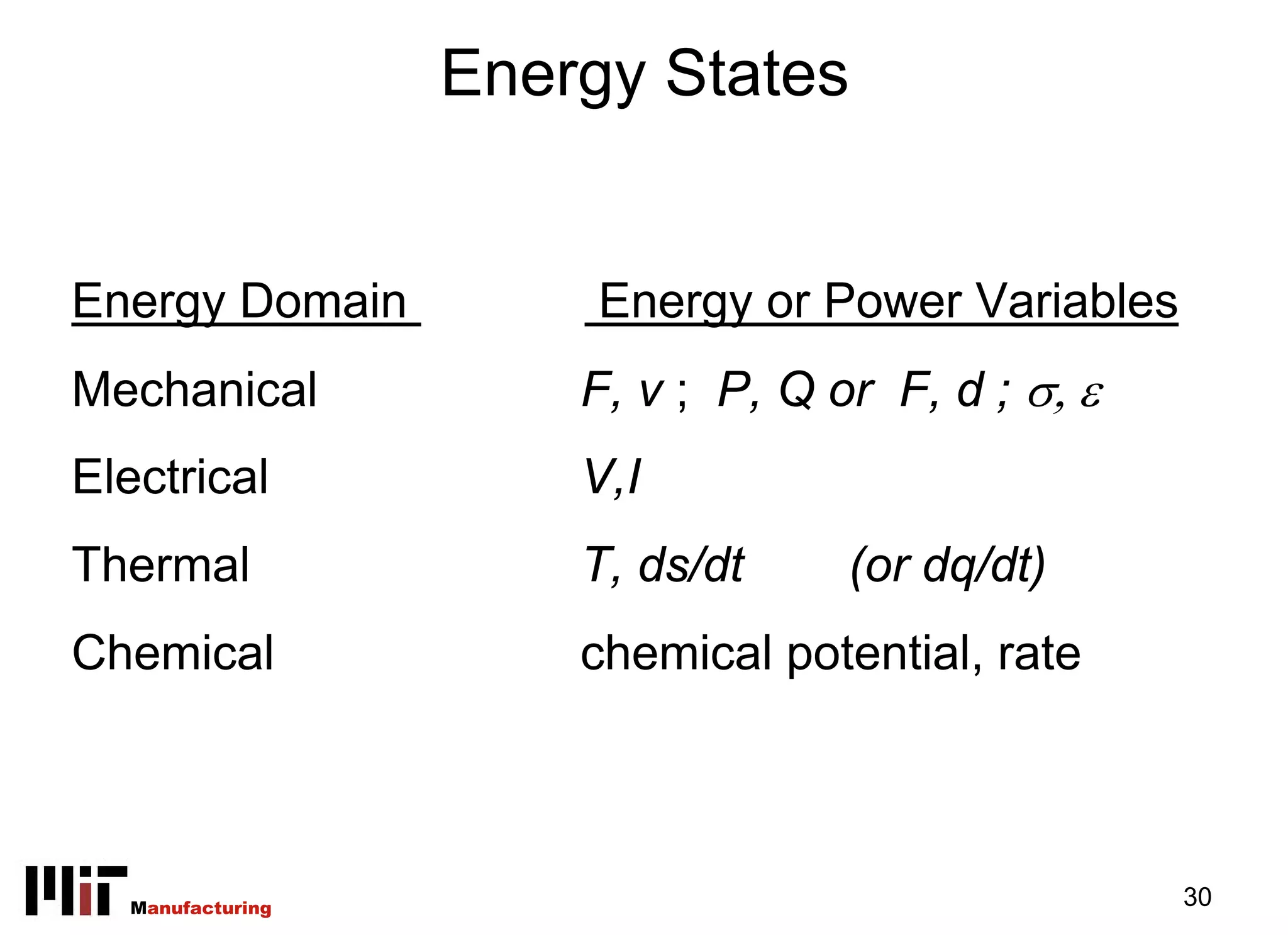

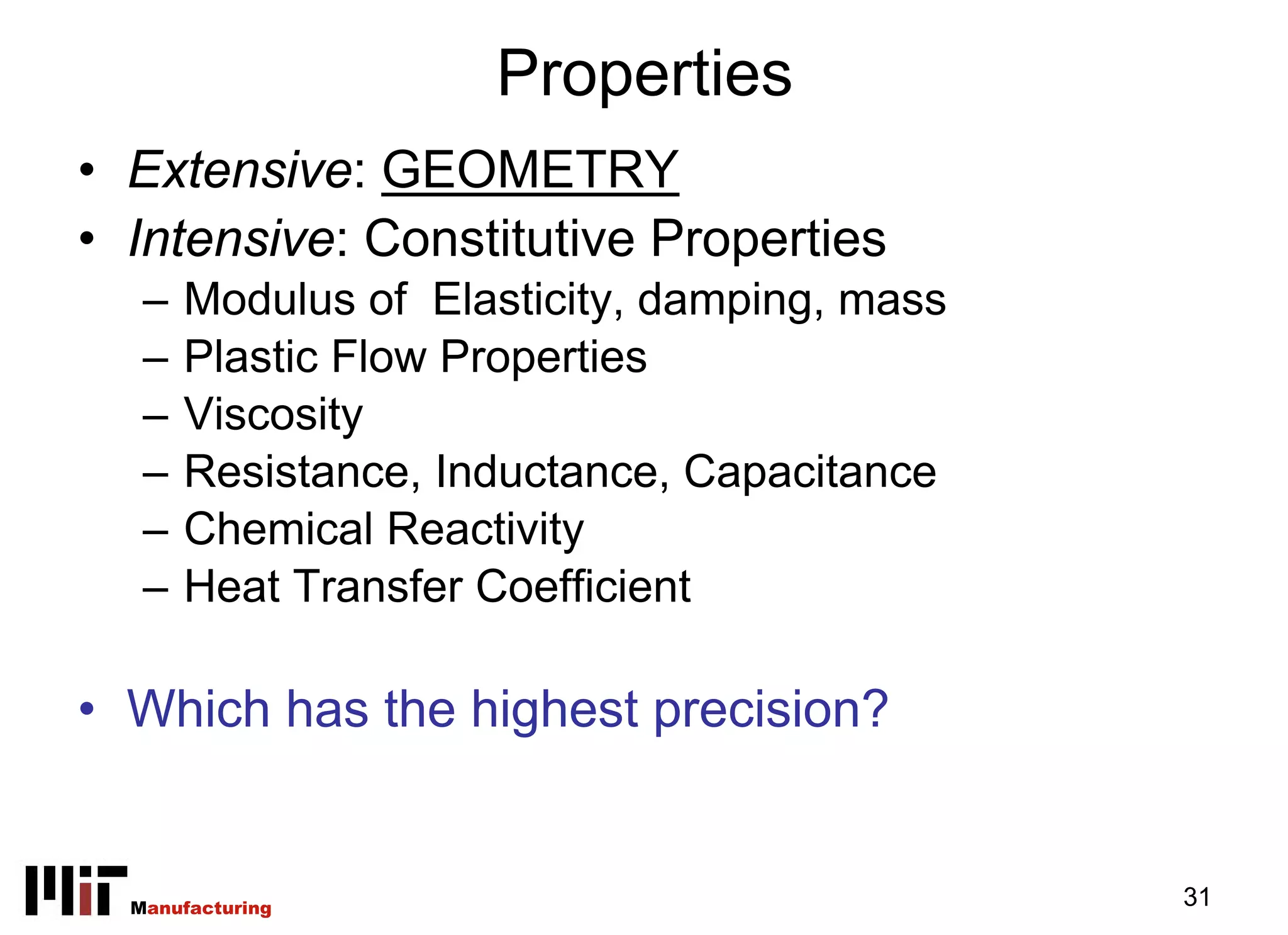

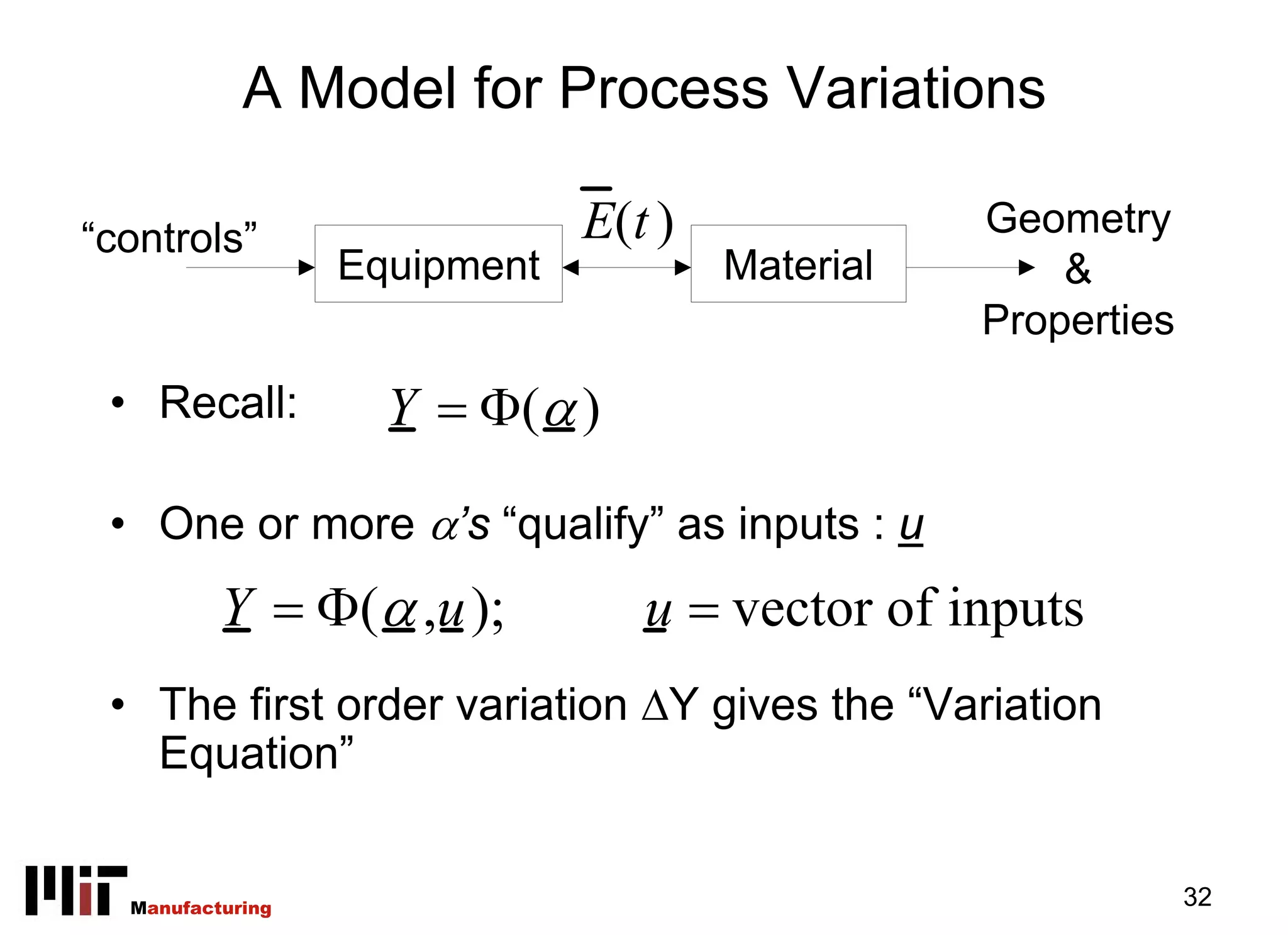

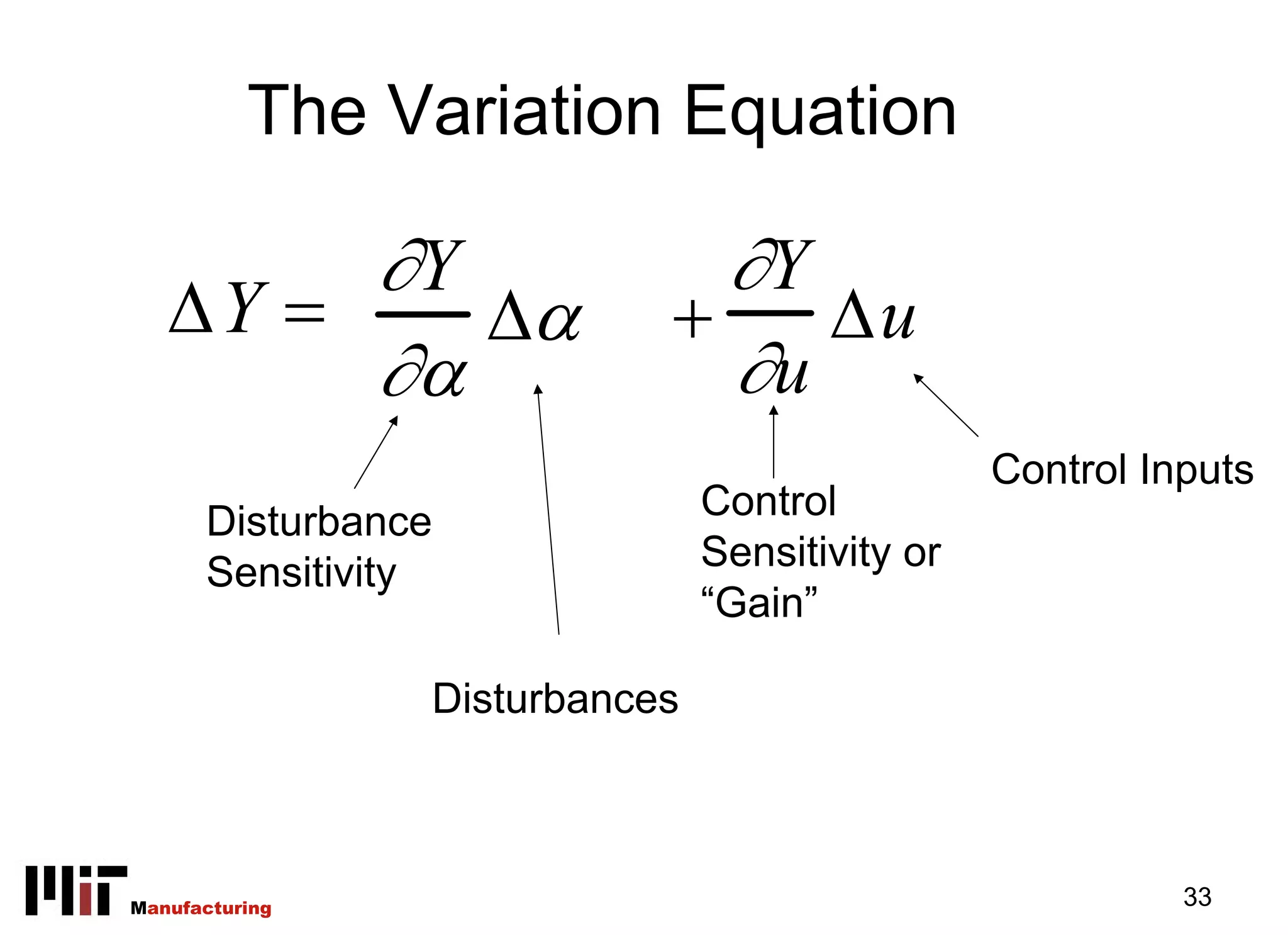

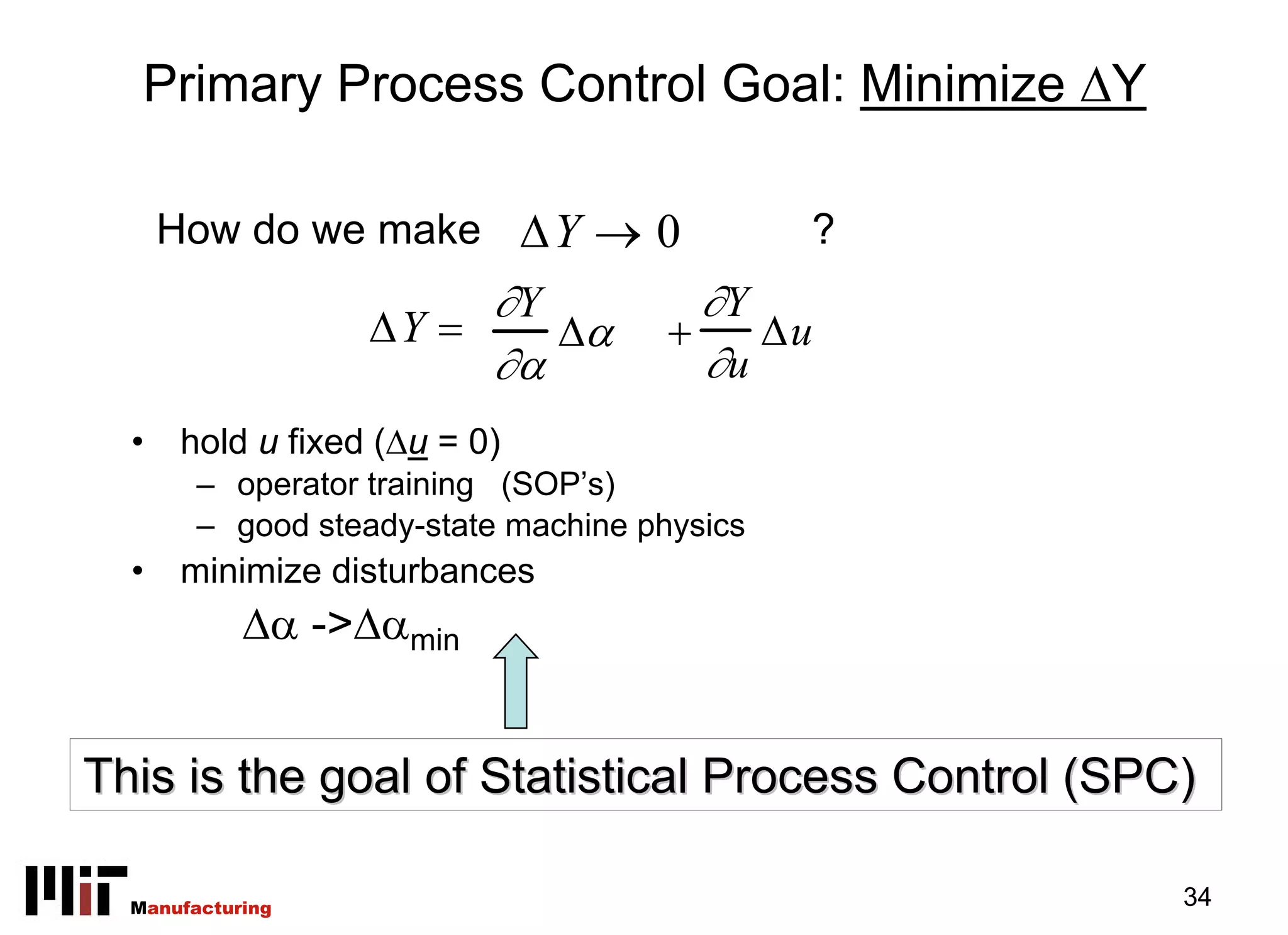

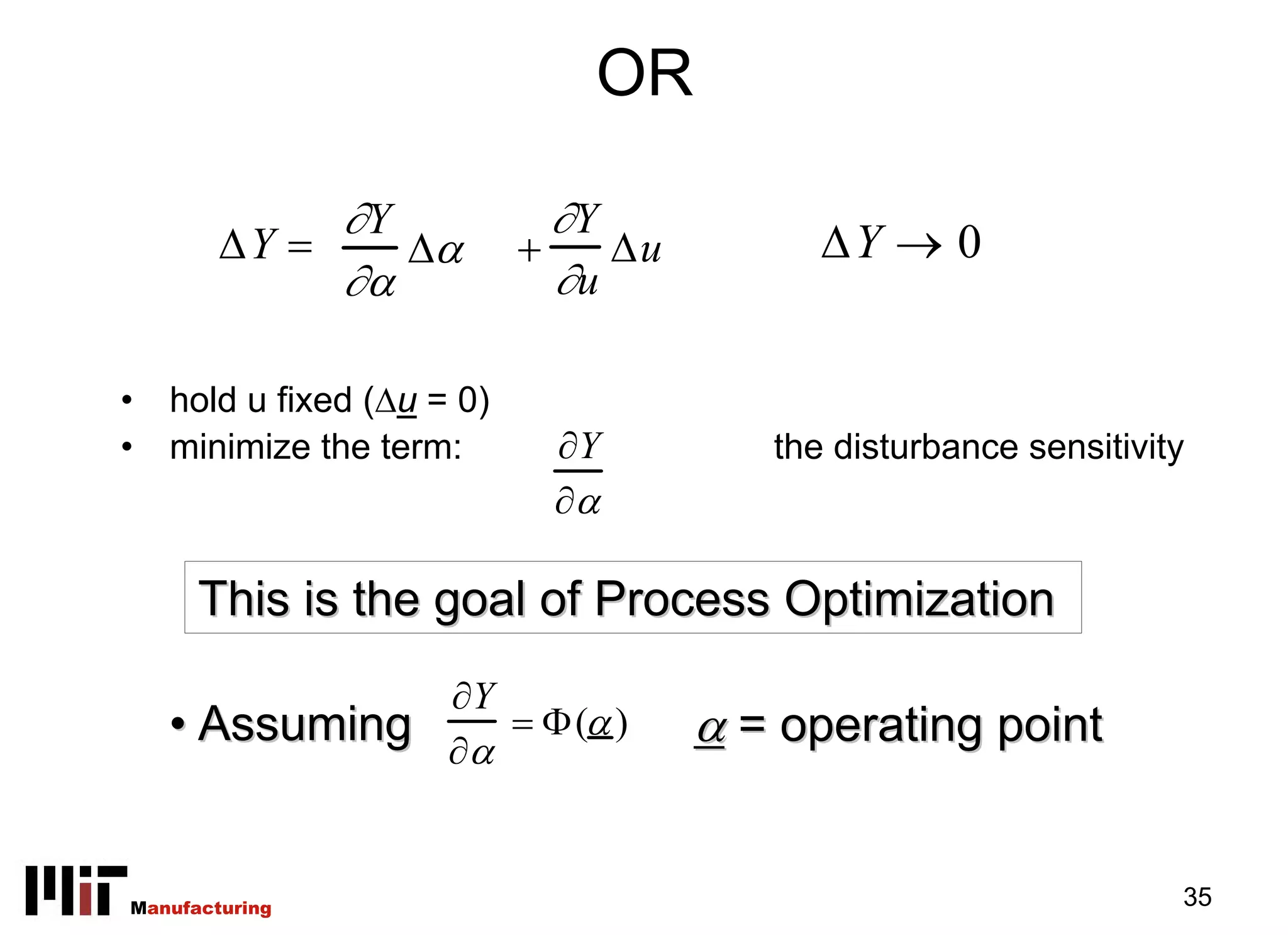

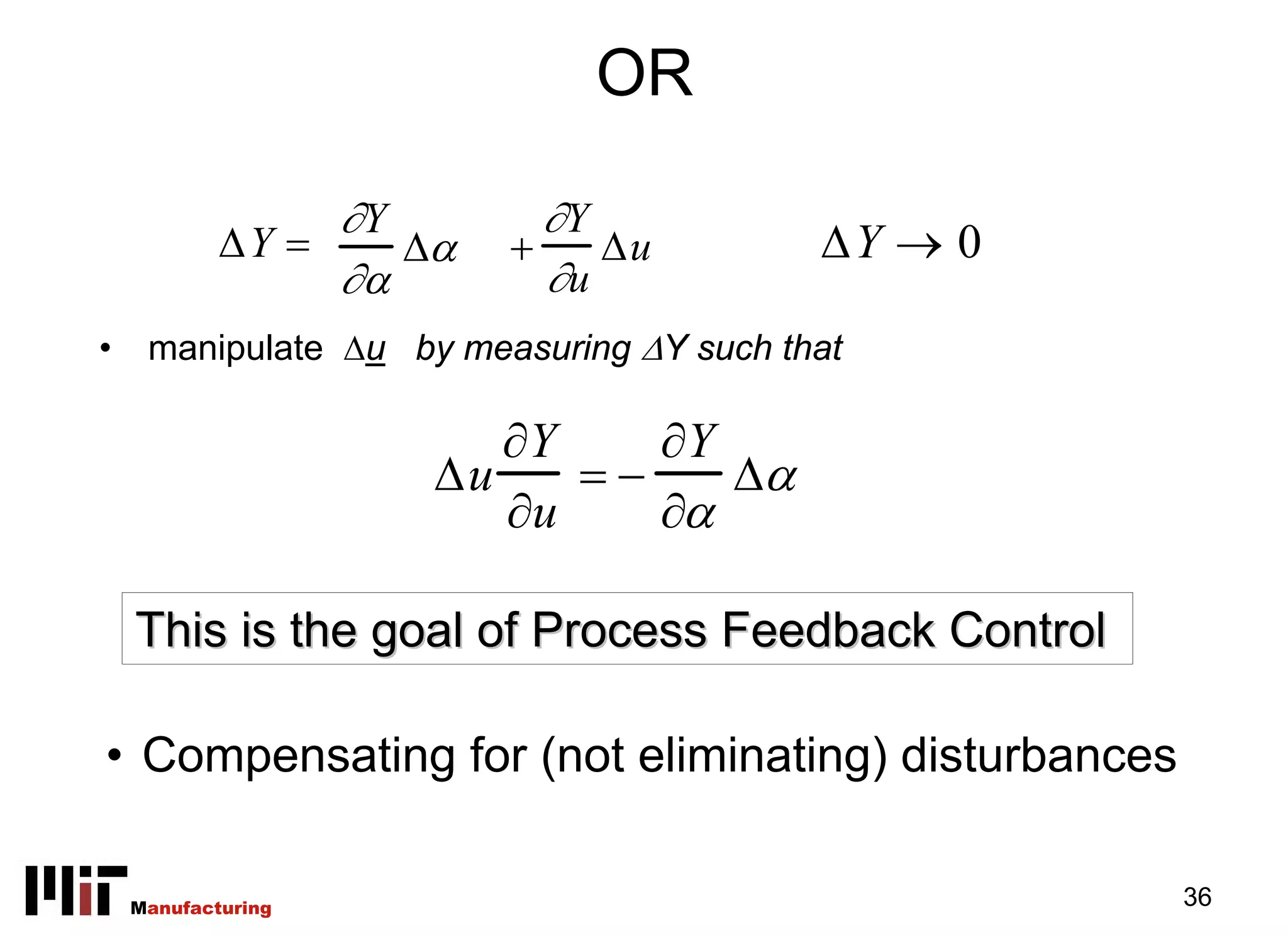

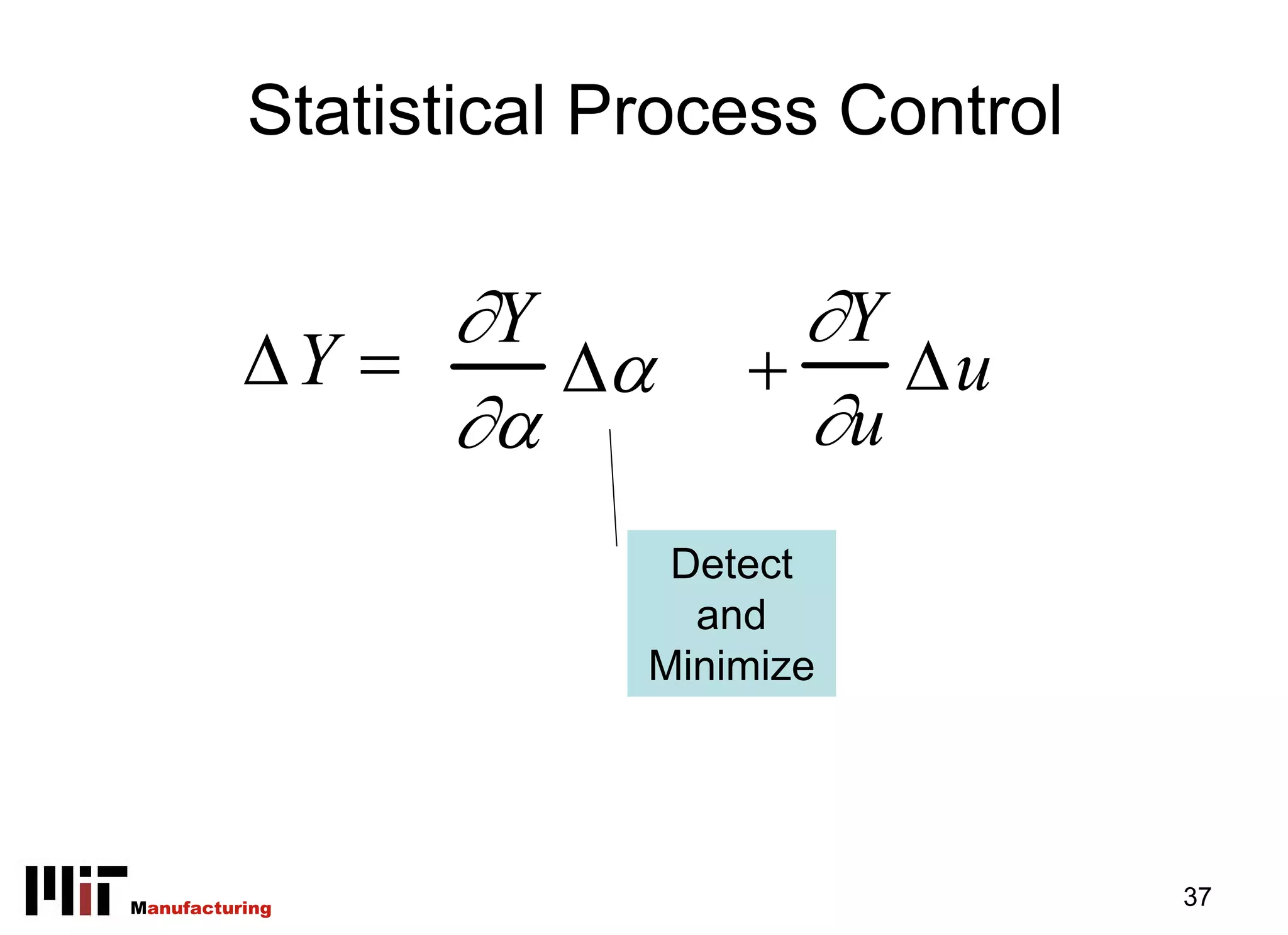

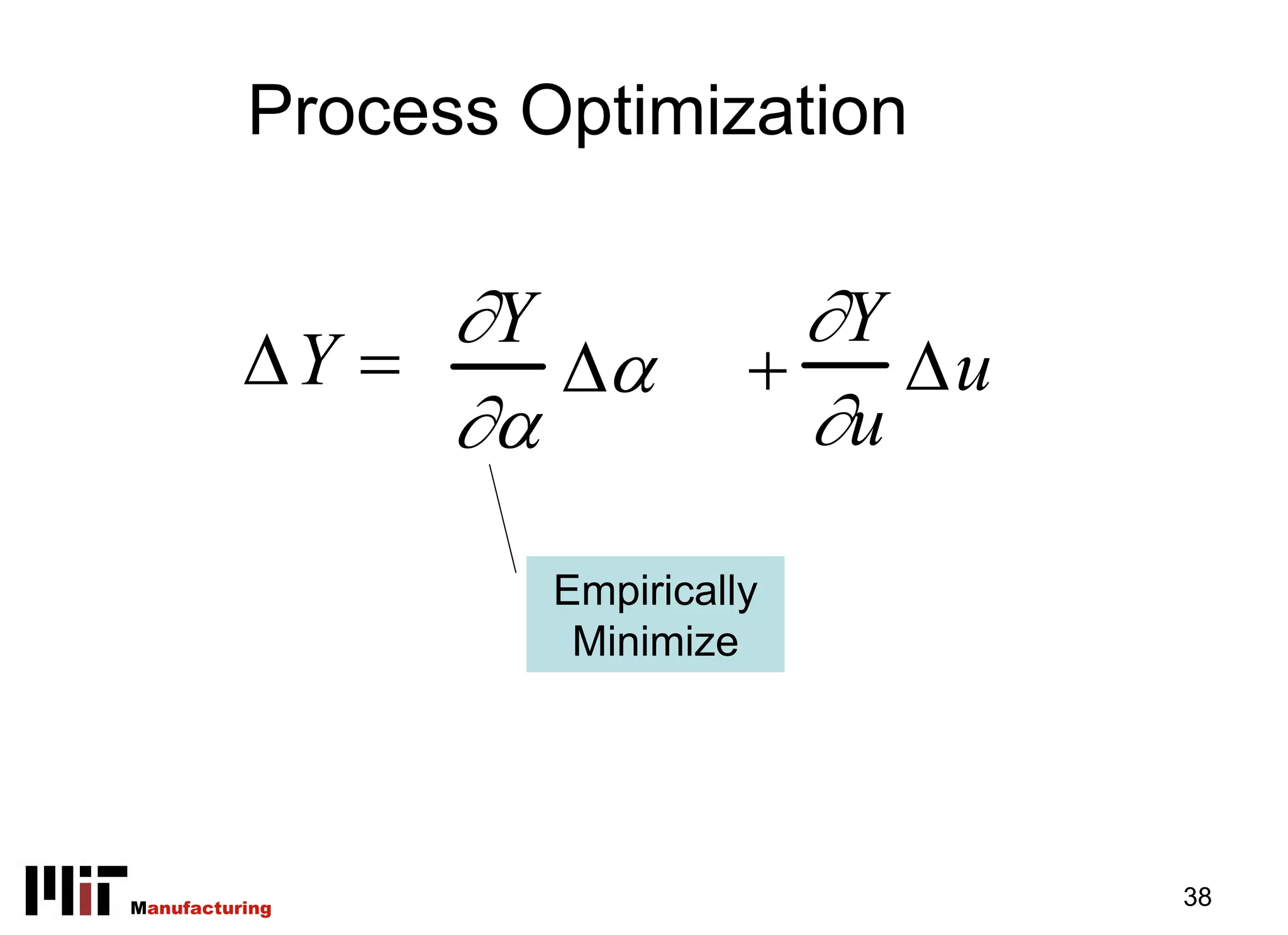

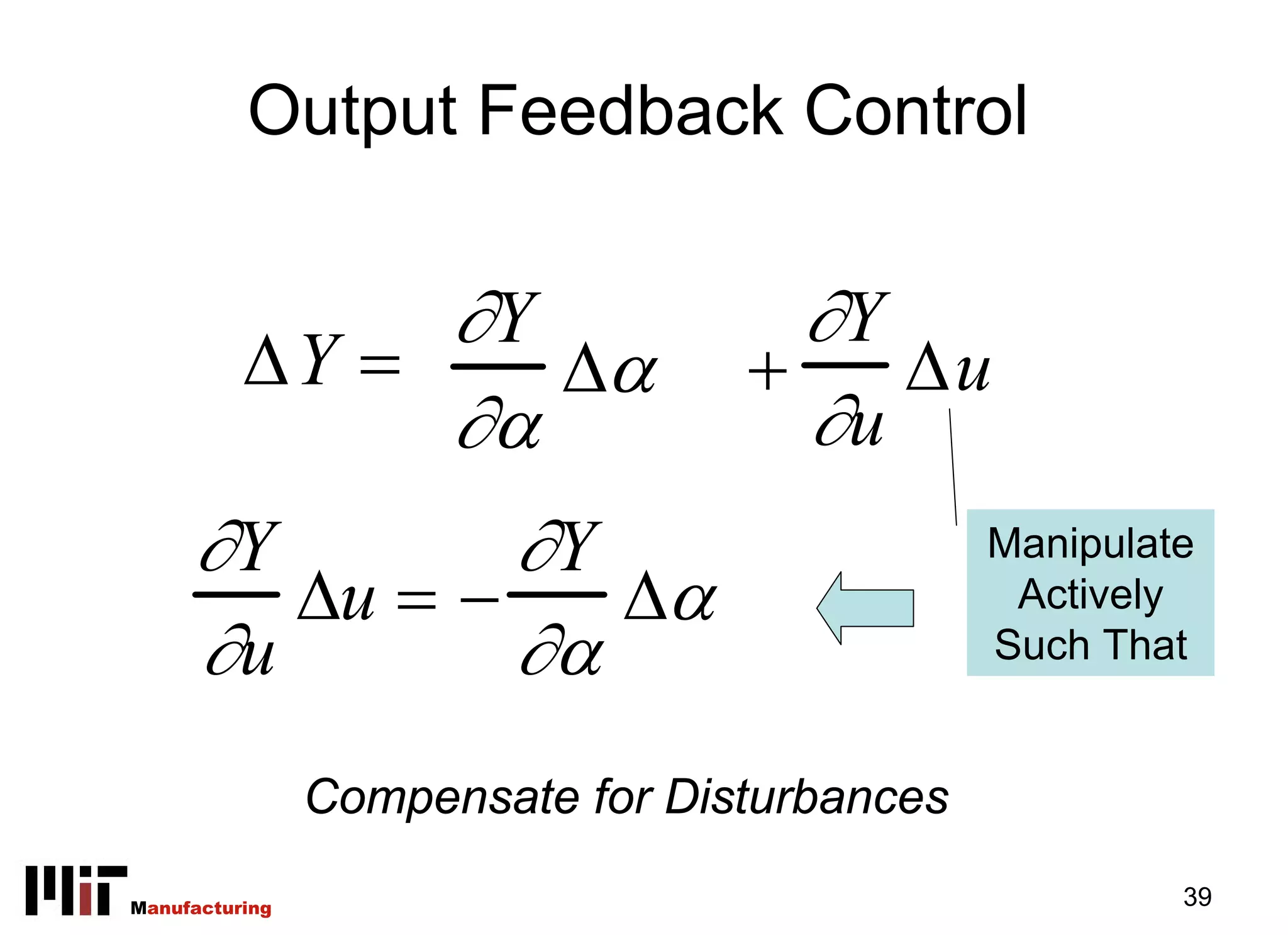

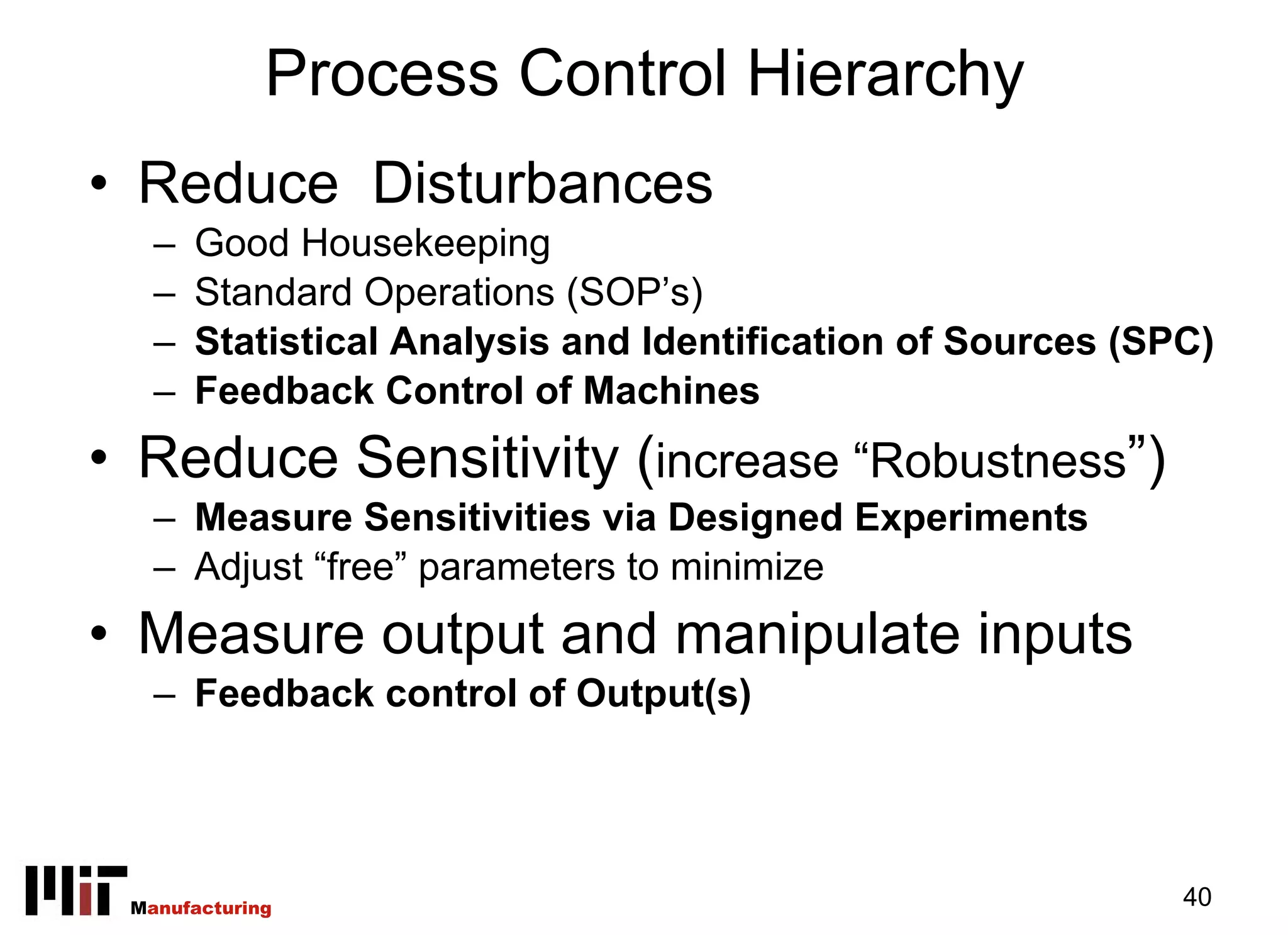

This document provides an overview of the MIT course 2.830J/6.780J/ESD.63J Control of Manufacturing Processes offered in Spring 2008. The course covers topics related to statistical process control, designed experiments, process optimization, and feedback control. It aims to maximize quality and throughput while improving flexibility and reducing costs. Key concepts discussed include sources of process variation, statistical models, effects models, and techniques for process optimization and control.