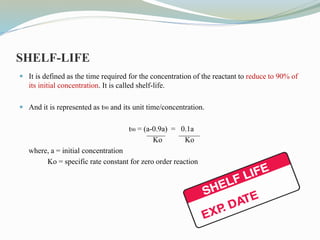

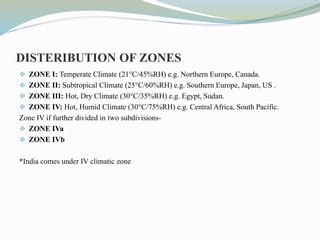

The document discusses the importance of stability studies for pharmaceutical products to determine shelf-life and ensure quality, safety, and efficacy over time. It outlines regulatory guidelines for stability testing, including storage conditions and frequencies of analysis. The interpretation of stability study results and conclusion that testing must be done according to specifications throughout a product's shelf-life are also summarized.