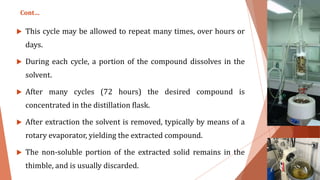

The document discusses the Soxhlet extraction method, an important process for extracting chemical constituents from plant materials using hot organic solvents. It describes the design and functioning of the Soxhlet extractor, which consists of a percolator, thimble, and siphon, allowing for continuous extraction and recycling of solvents over extended periods. Although efficient, the method has drawbacks such as long operation times and the need for solvent evaporation after extraction.