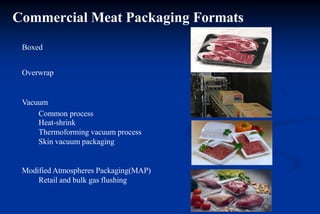

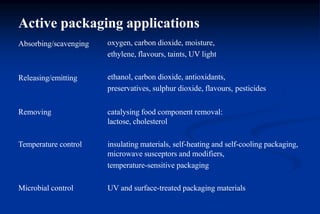

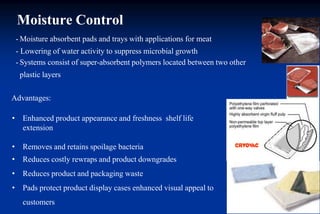

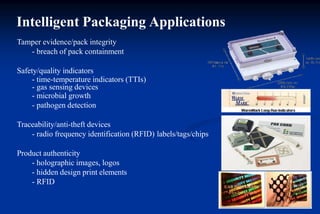

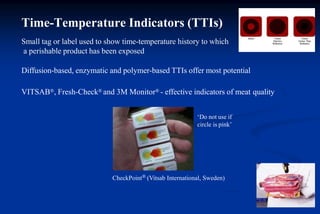

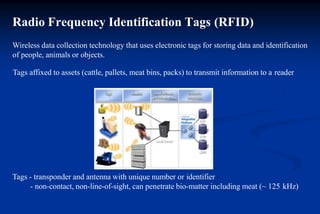

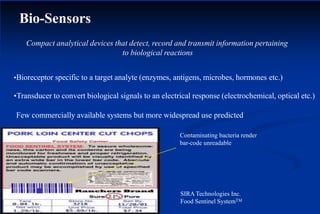

This document provides an overview of active and intelligent packaging technologies used in the meat industry. It discusses various types of active packaging like oxygen scavengers, carbon dioxide emitters, and antimicrobial packaging that can help extend the shelf-life of meat products. It also covers intelligent packaging technologies such as time-temperature indicators, gas sensors, and radio frequency identification tags that can monitor meat quality during transport and storage. The document concludes that these advanced packaging technologies are expected to grow significantly to meet consumer demands and reduce food waste.