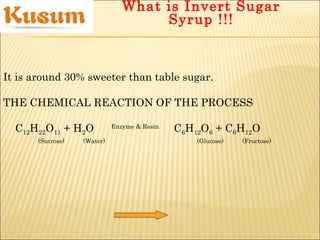

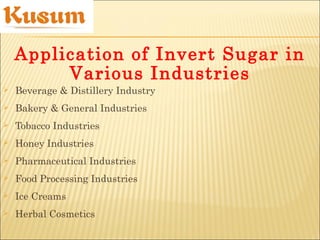

Invert Sugar India Pvt. Ltd. was founded in 1997 and began commercial production of invert sugar syrup in 2001, utilizing advanced technology and maintaining R&D facilities in Gwalior. The company holds multiple ISO certifications and collaborates with national research bodies for technology transfer. Invert sugar syrup offers benefits such as enhanced sweetness, flavor retention, and extended shelf life across various industries including beverages, bakery, and pharmaceuticals.