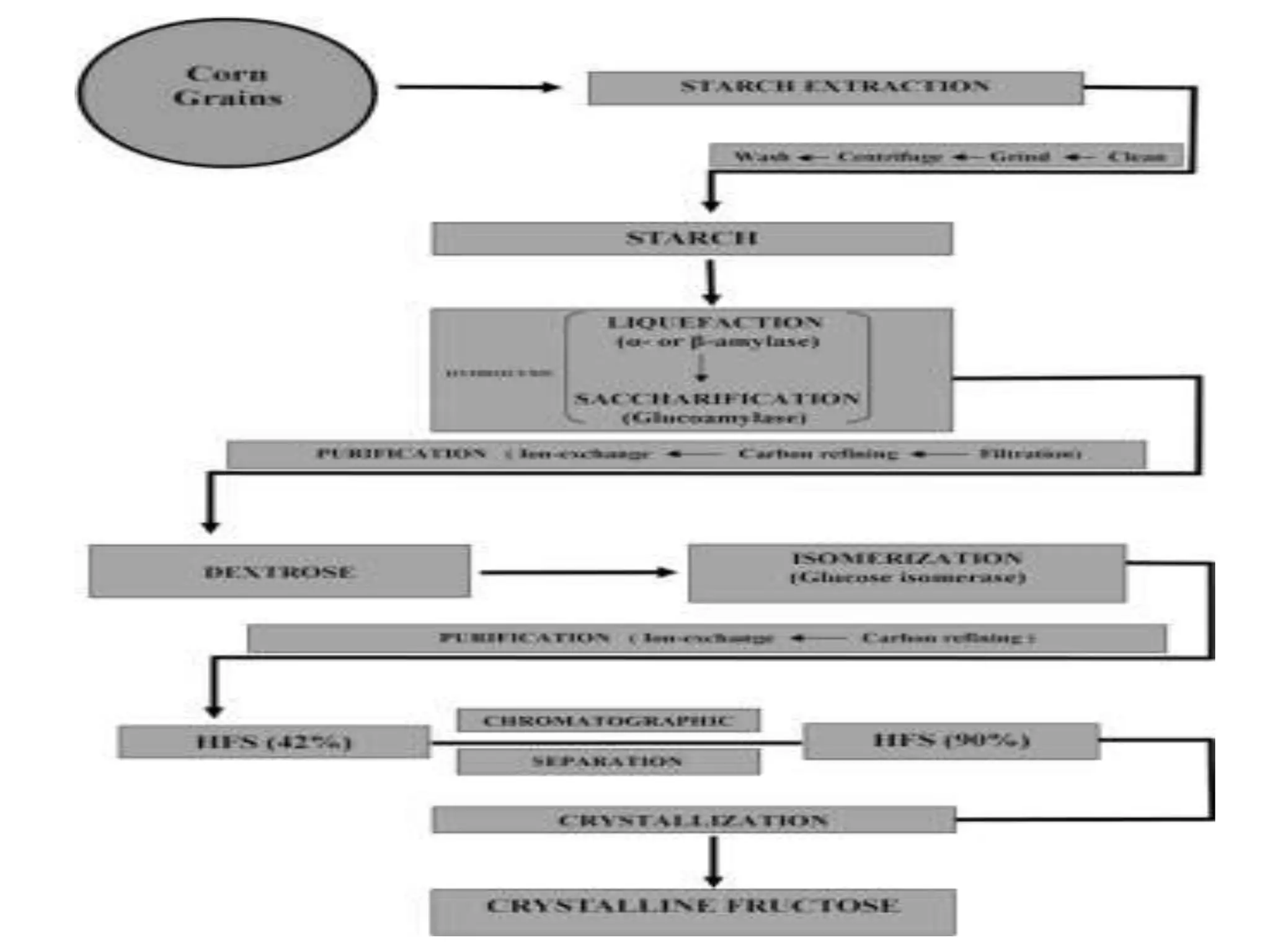

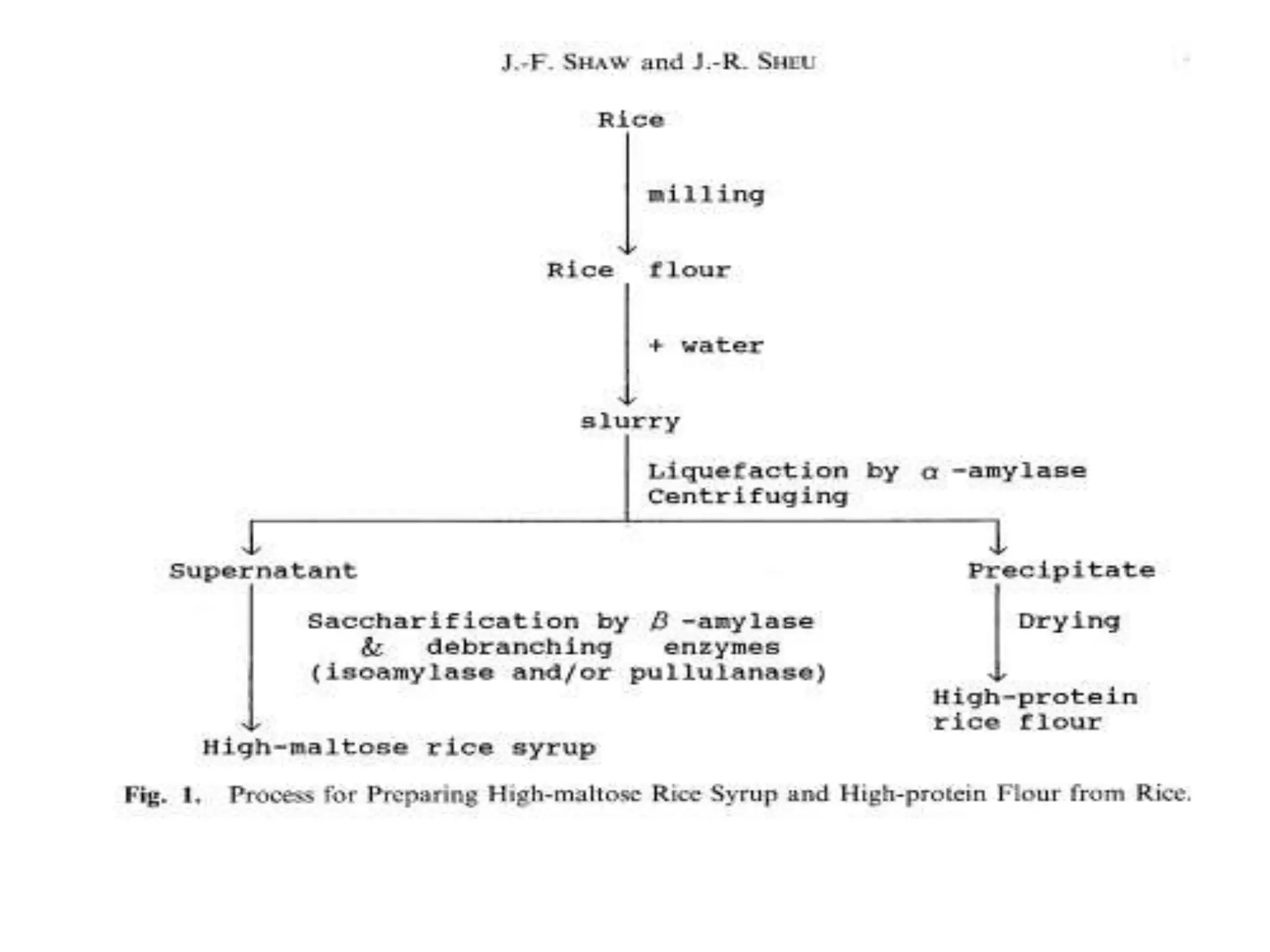

This document discusses high fructose corn syrup (HFCS) and maltose syrup. It describes the process for making HFCS, which involves processing corn starch with enzymes like amylases and glucose isomerase to convert glucose into fructose. An alternative method uses inulinase enzymes on inulin to produce 95% fructose yield. Maltose syrup is made through a process of mixing starch with water and enzymes like amylases, then filtering, concentrating, and crystallizing to produce a syrup high in maltose. Both HFCS and maltose syrup are used as sweeteners in food production.