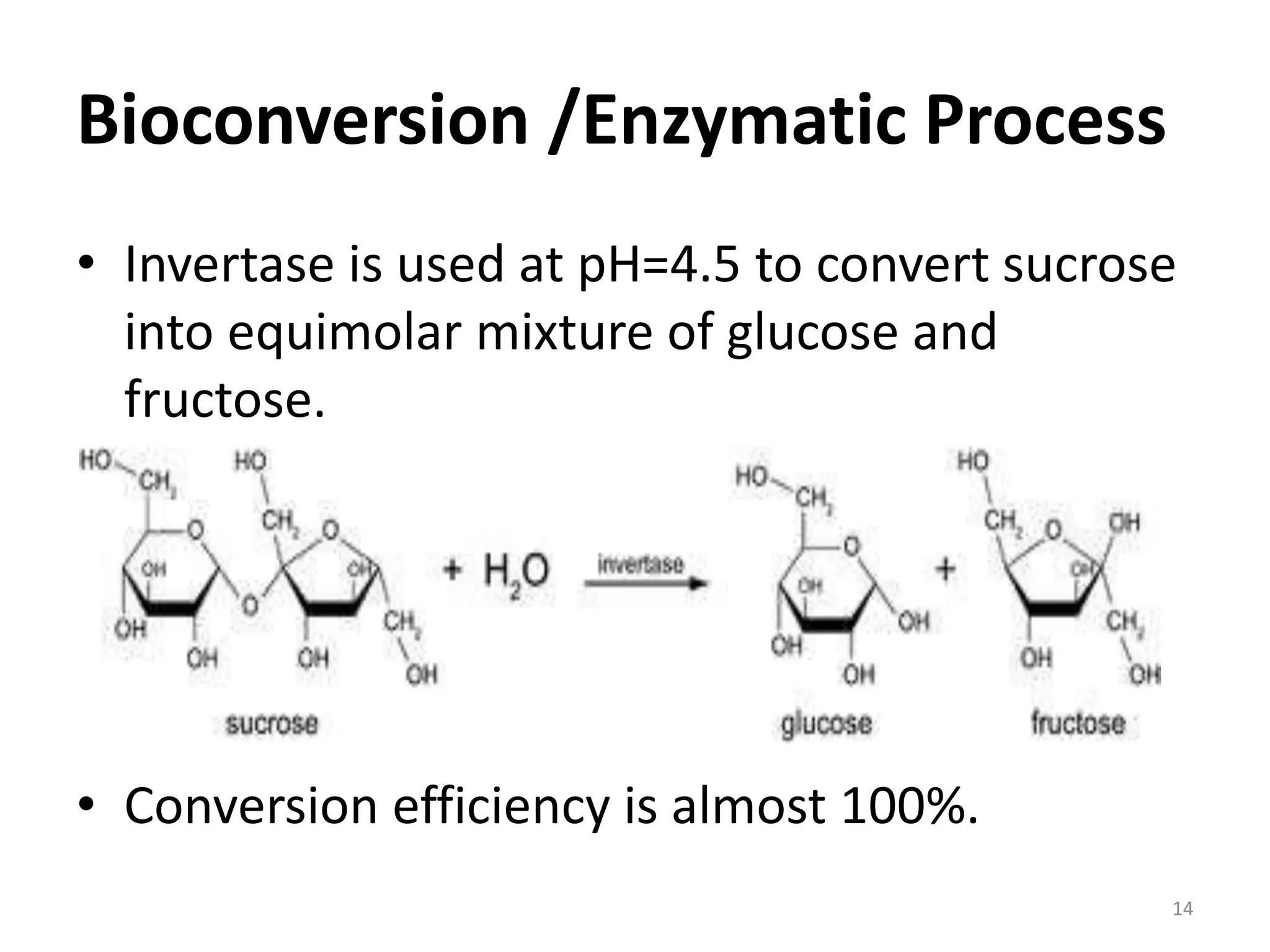

This document discusses glucose syrup and invert sugar syrups. Glucose syrup is made from starch hydrolysis and typically contains 10-43% glucose. It is produced through soaking, gelatinization, hydrolysis, clarification, and evaporation steps. Invert syrup contains equal proportions of glucose and fructose produced through acid or enzymatic hydrolysis of sucrose. Both syrups are used as sweeteners and thickeners in foods like candy, ice cream, and baked goods due to properties like moisture retention and flavor enhancement. They have applications in confectionery, pharmaceuticals, and as flavoring agents.