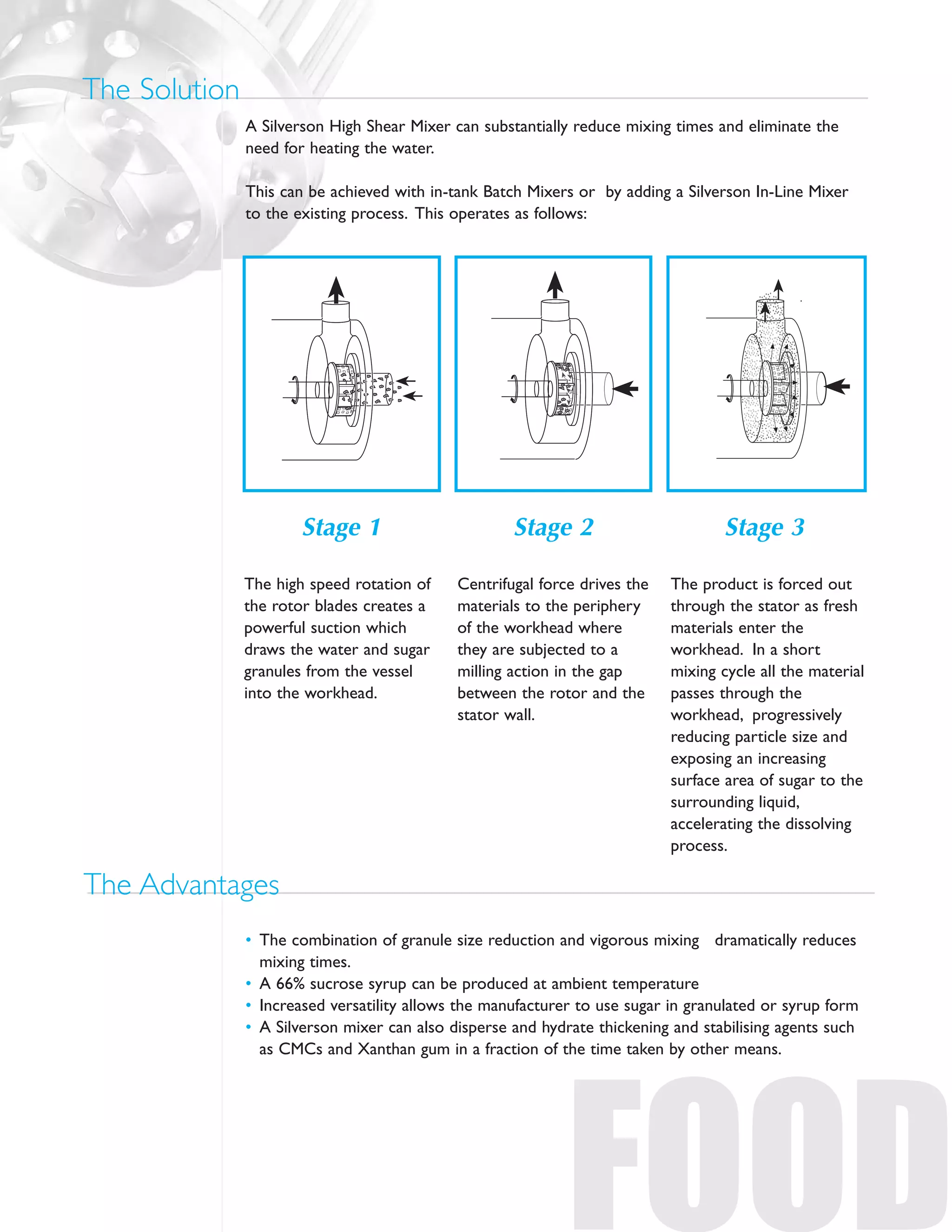

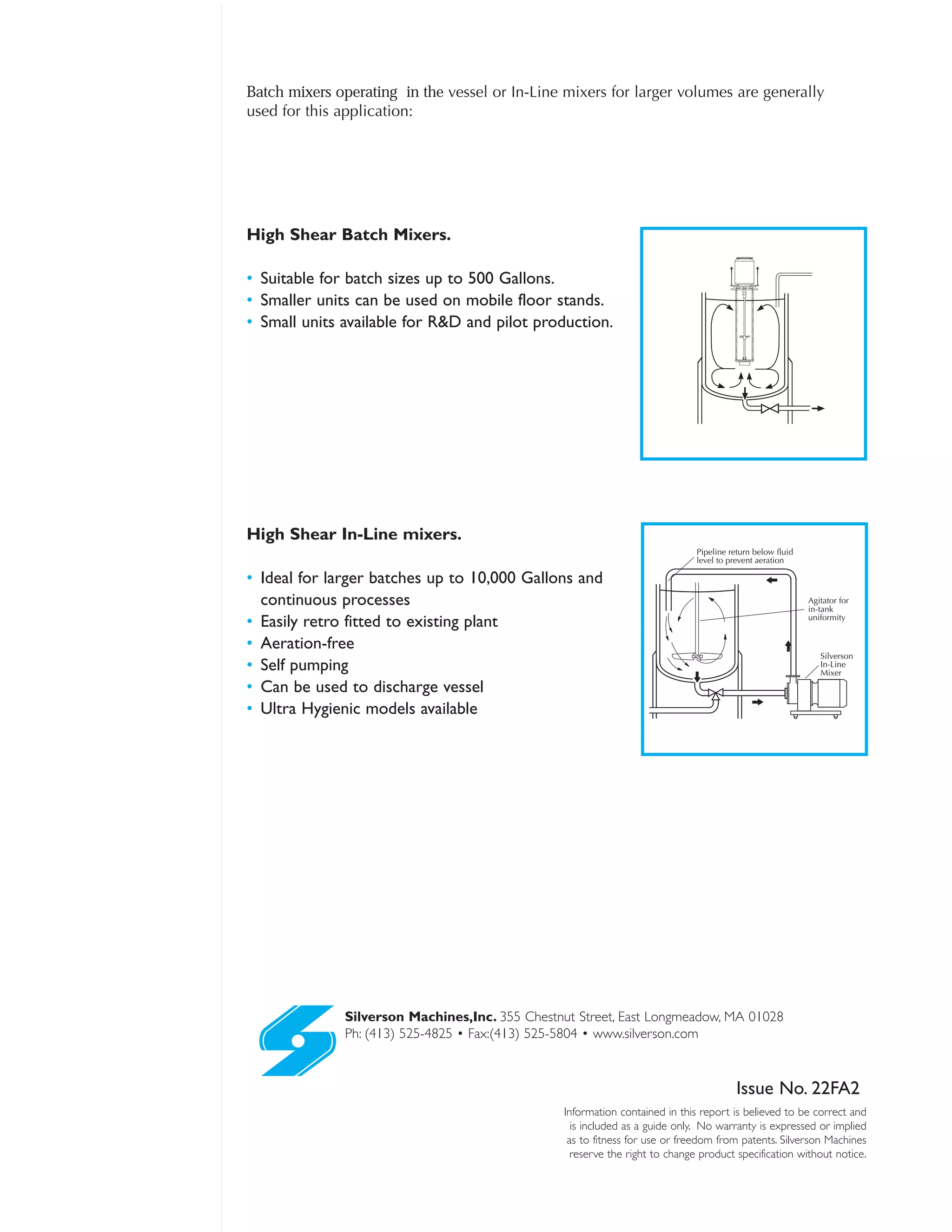

The document discusses the preparation of sugar syrups in soft drink manufacturing, highlighting the advantages of using high shear mixers to improve efficiency. It outlines the challenges of dissolving granulated sugar and the limitations of conventional methods such as heating, which can increase costs and complicate the process. Silverson high shear mixers are presented as a solution that reduces mixing times, allows for the use of both granulated and liquid sugars, and enhances the dispersion of other ingredients.