This document provides an introduction to Six Sigma, including:

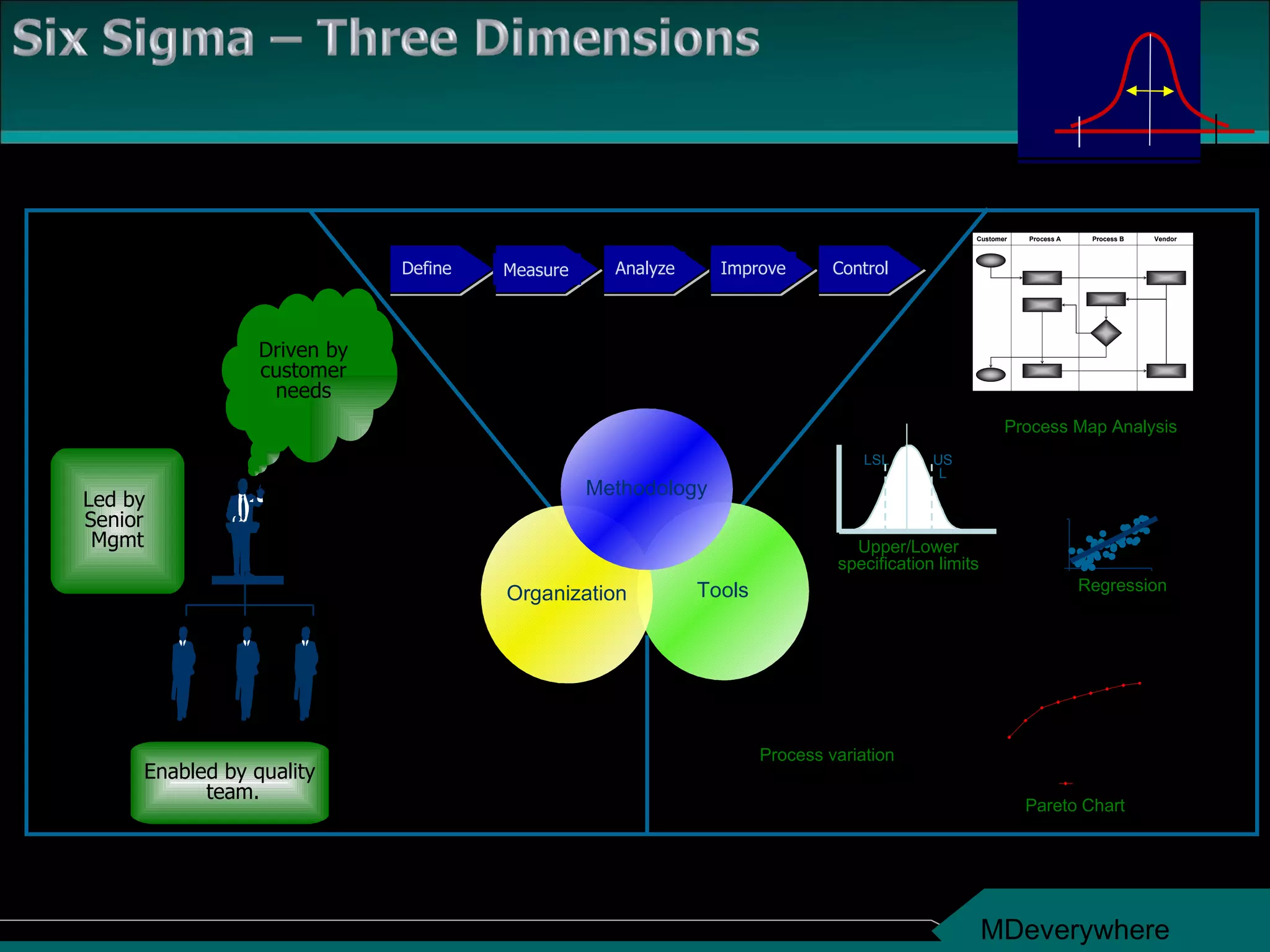

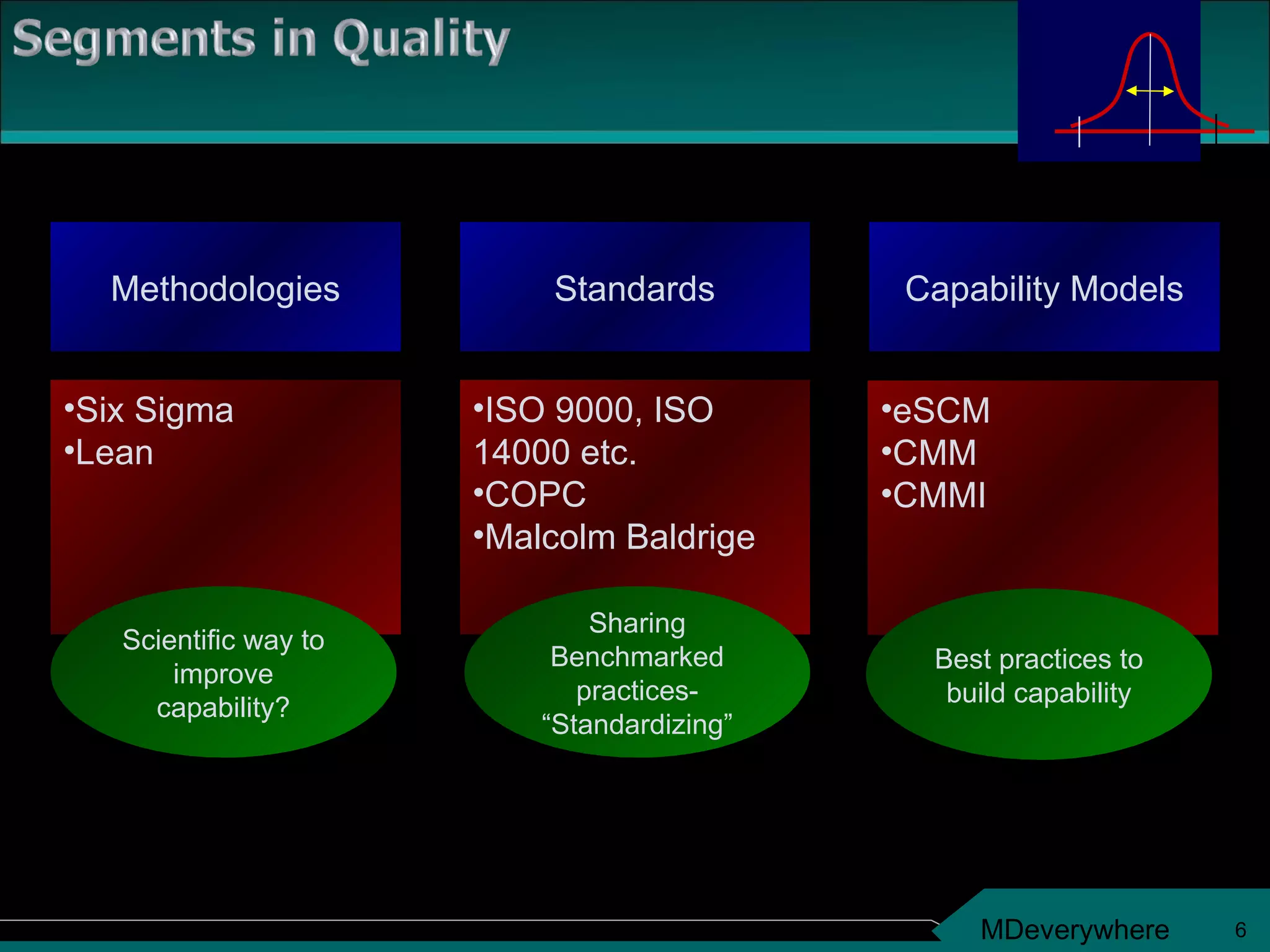

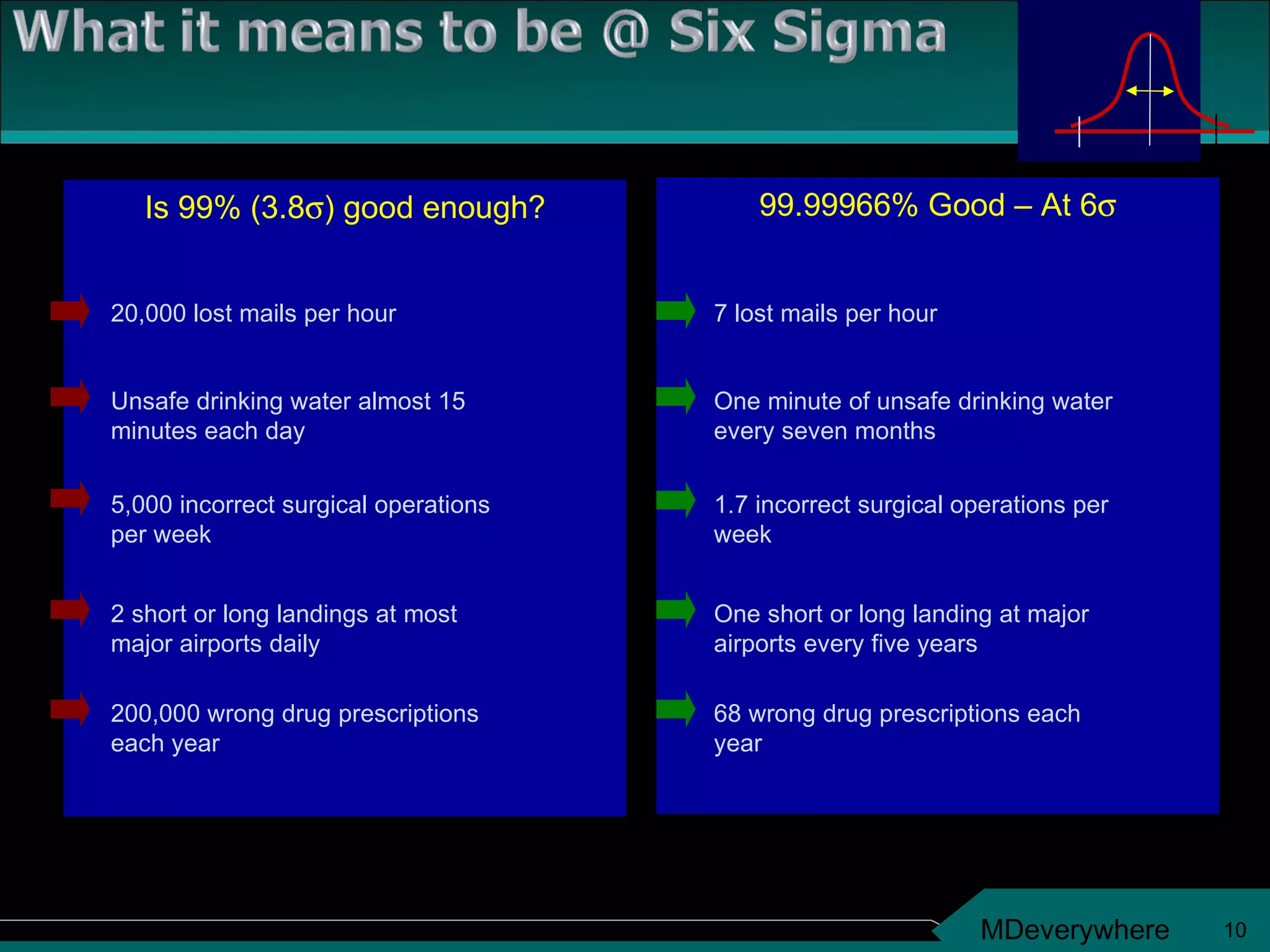

1) It describes Six Sigma as a data-driven methodology used for process improvement and achieving high quality standards.

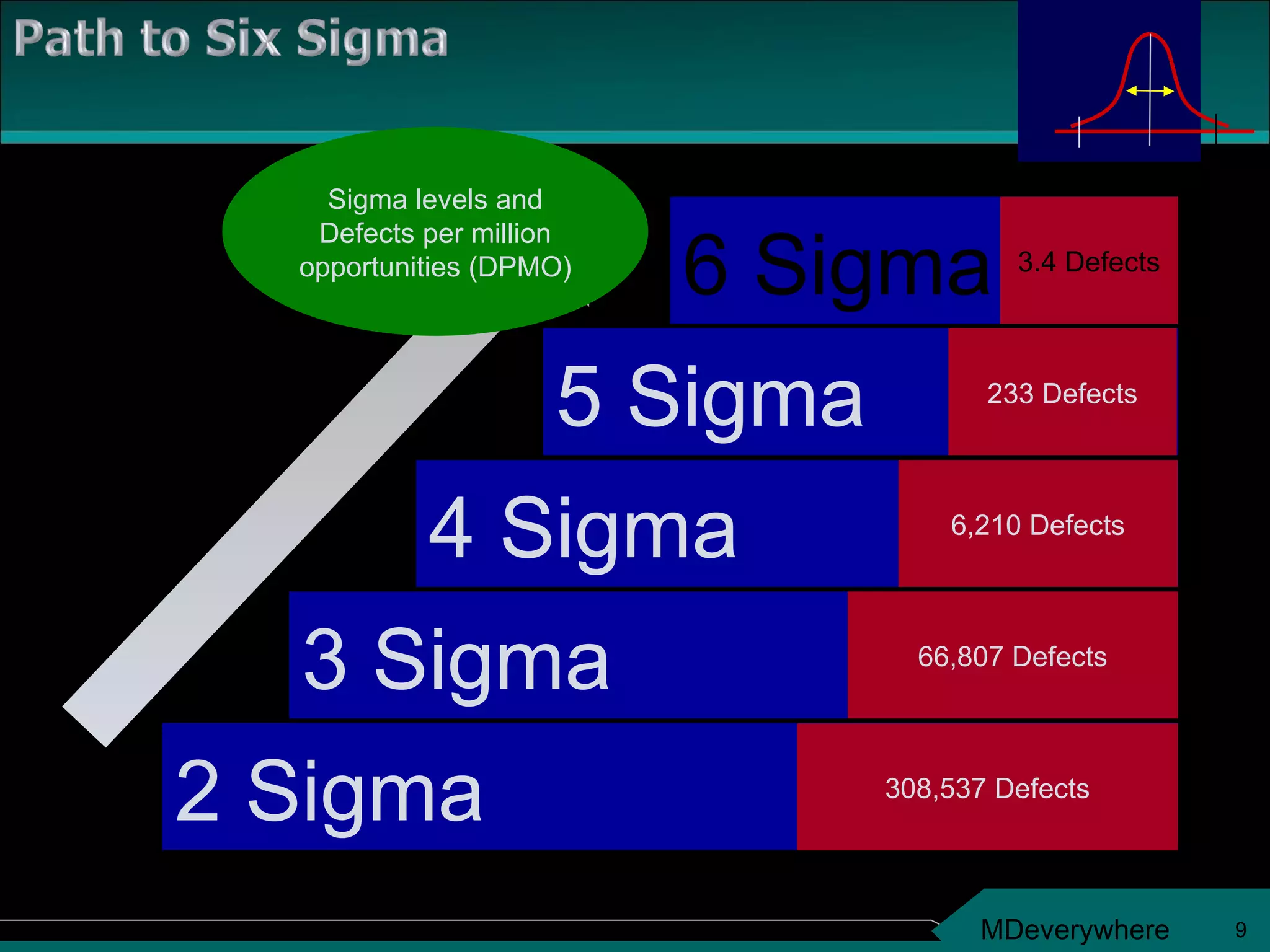

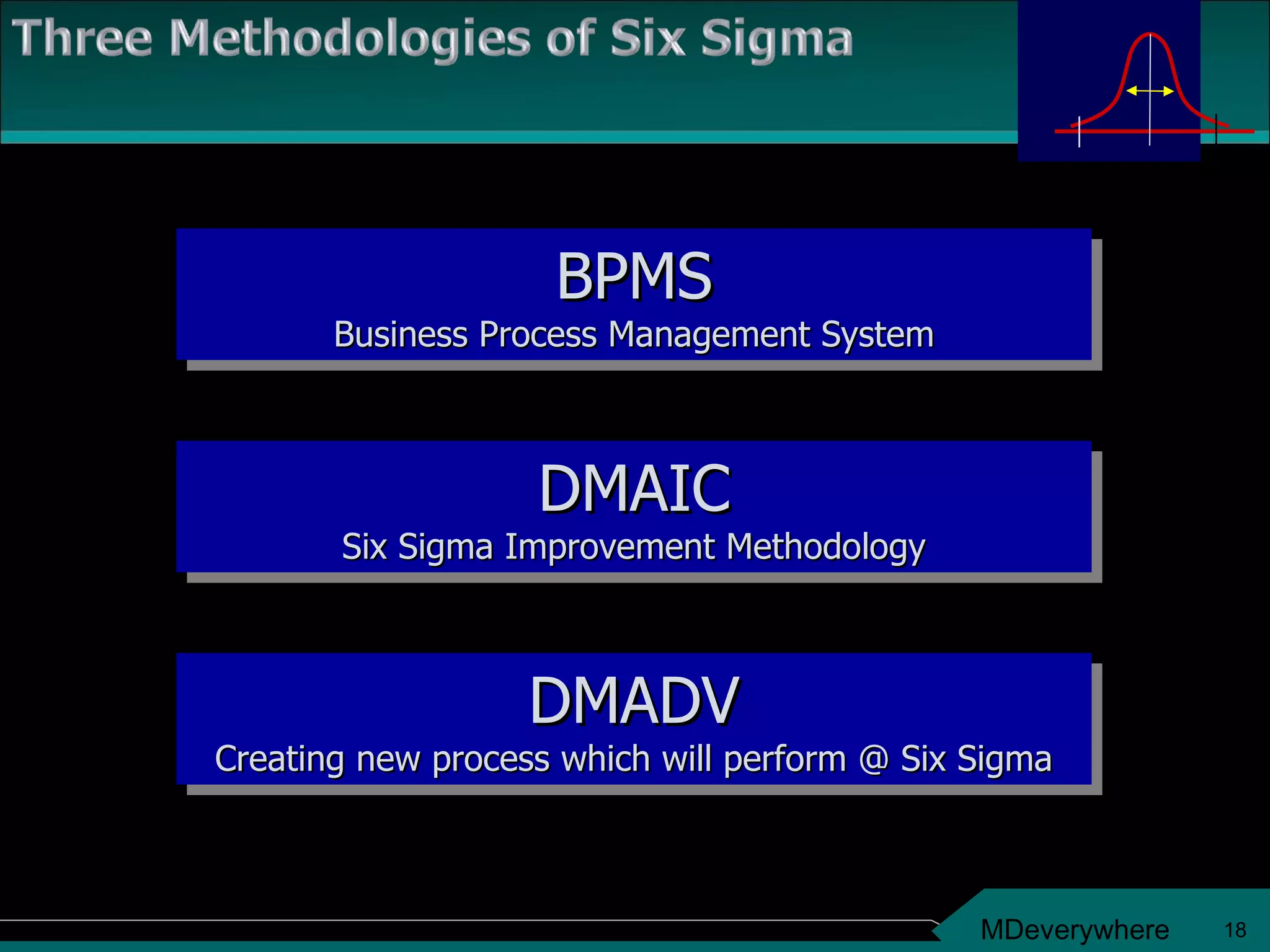

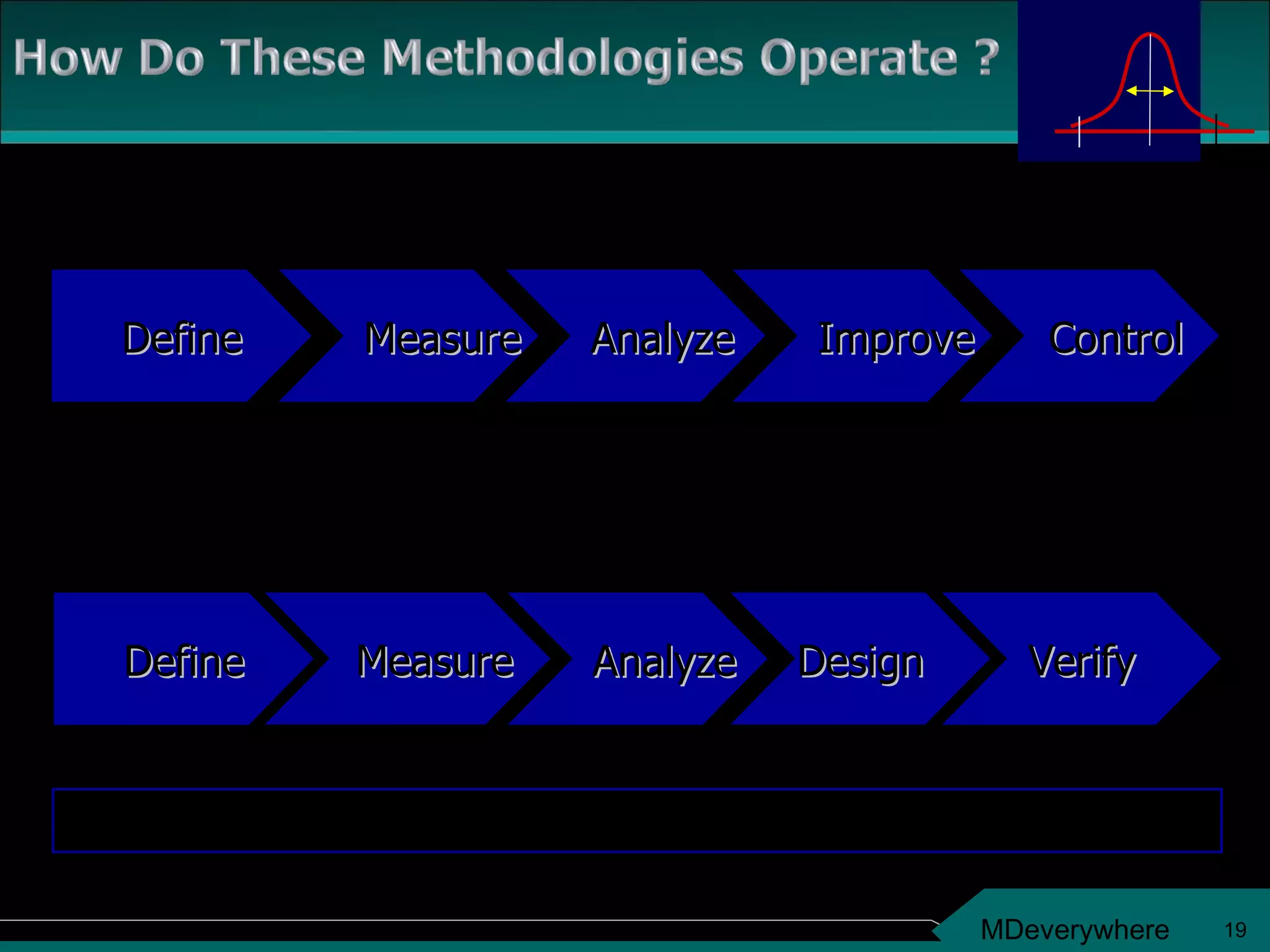

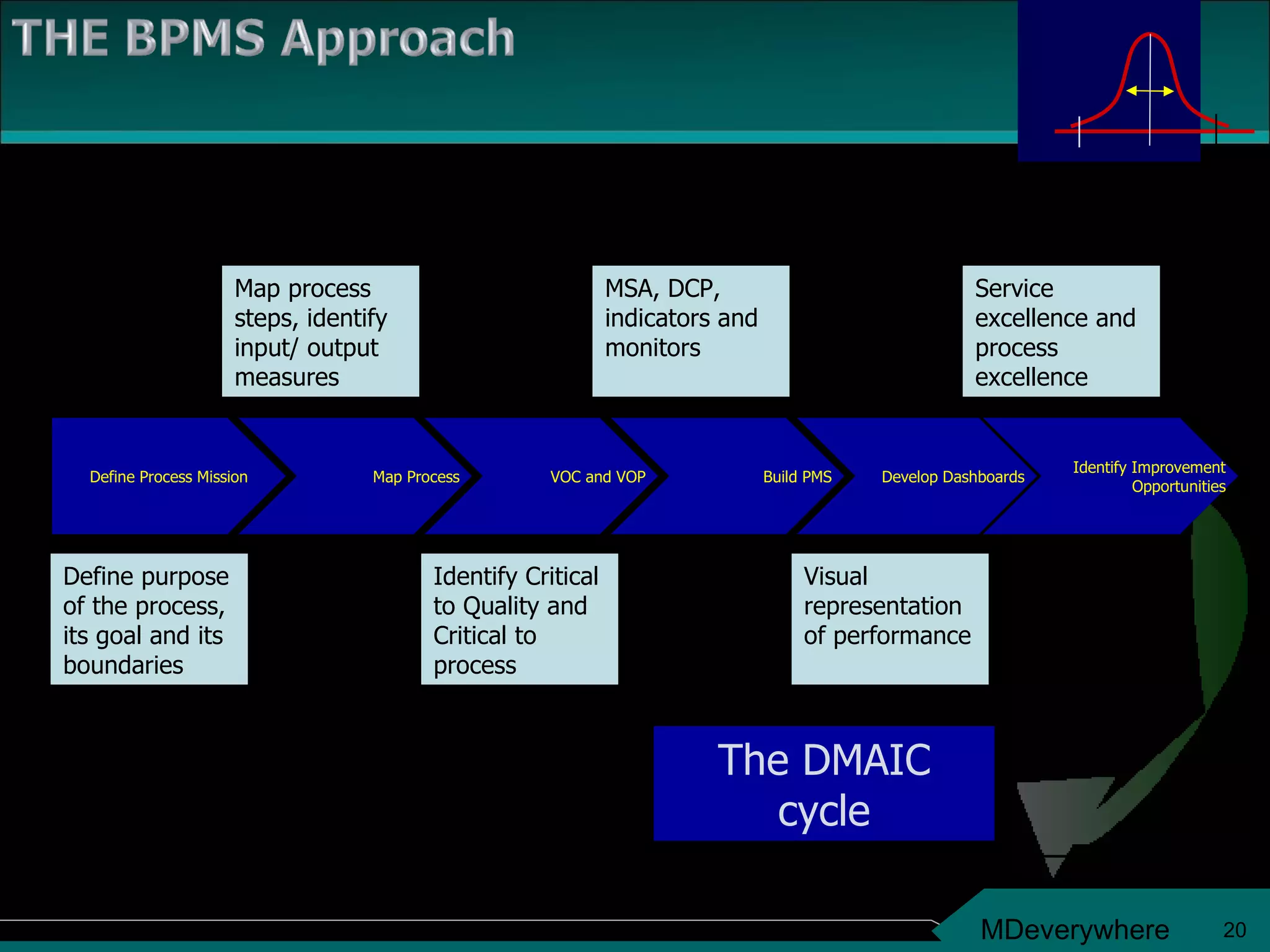

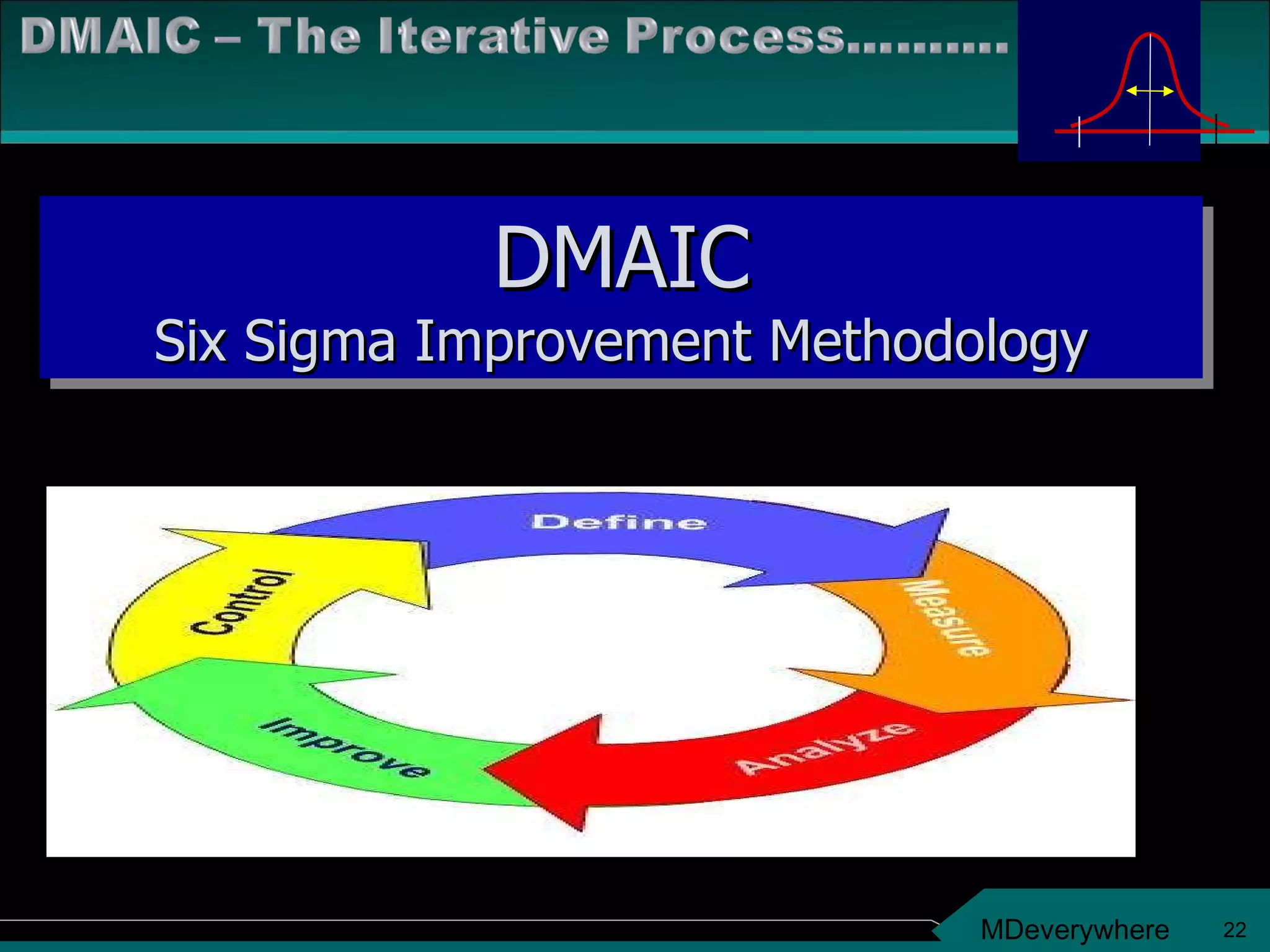

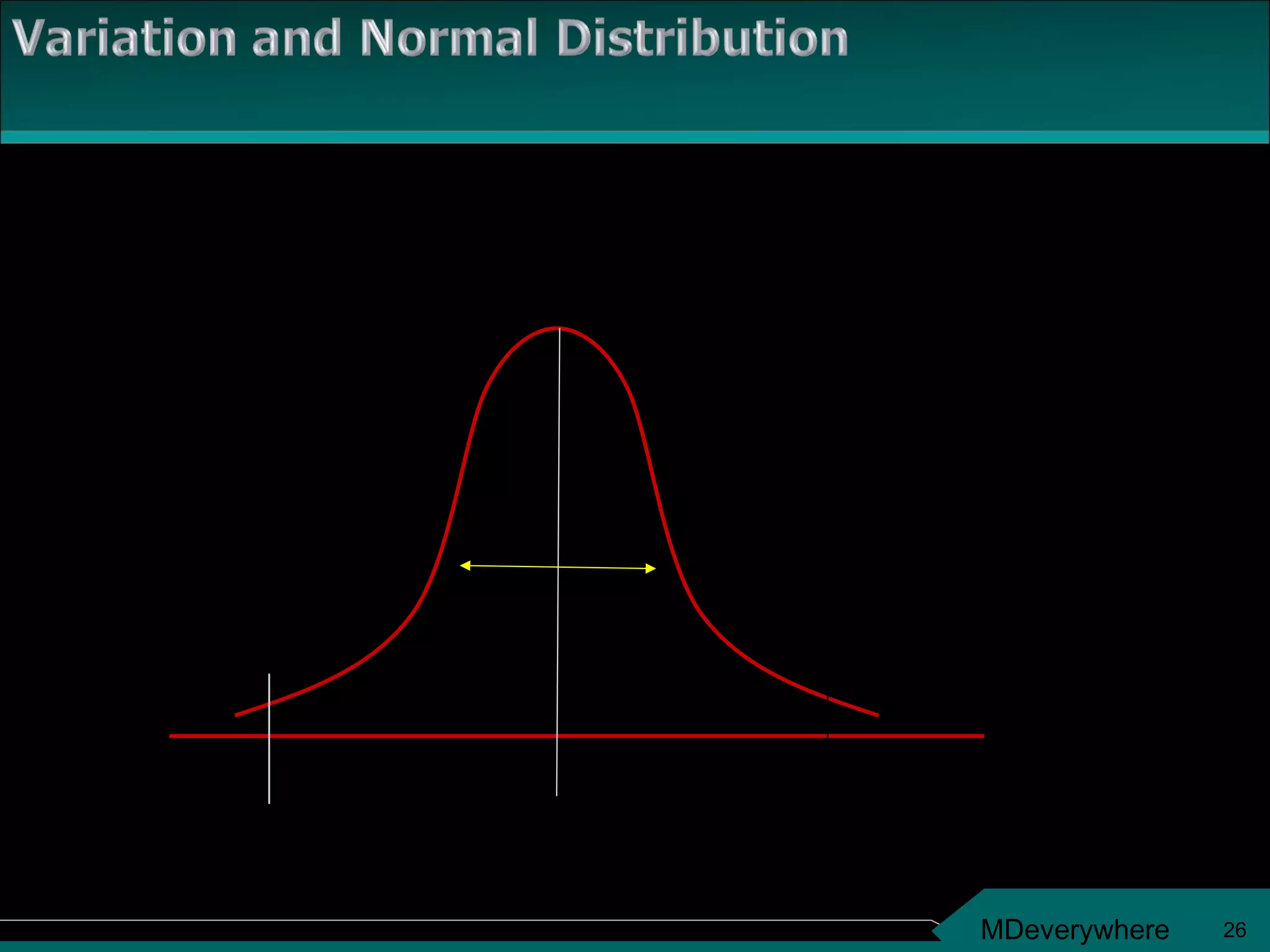

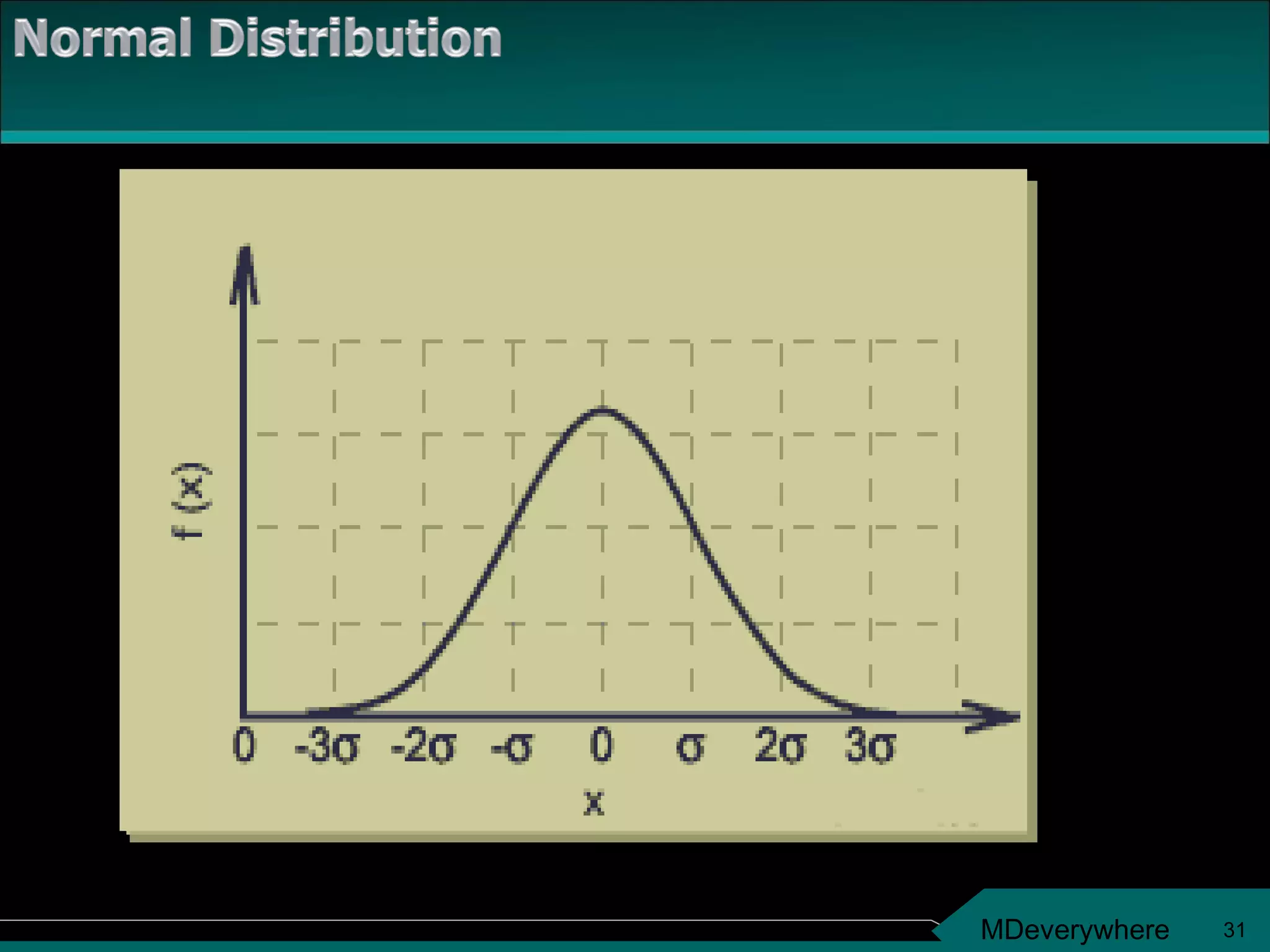

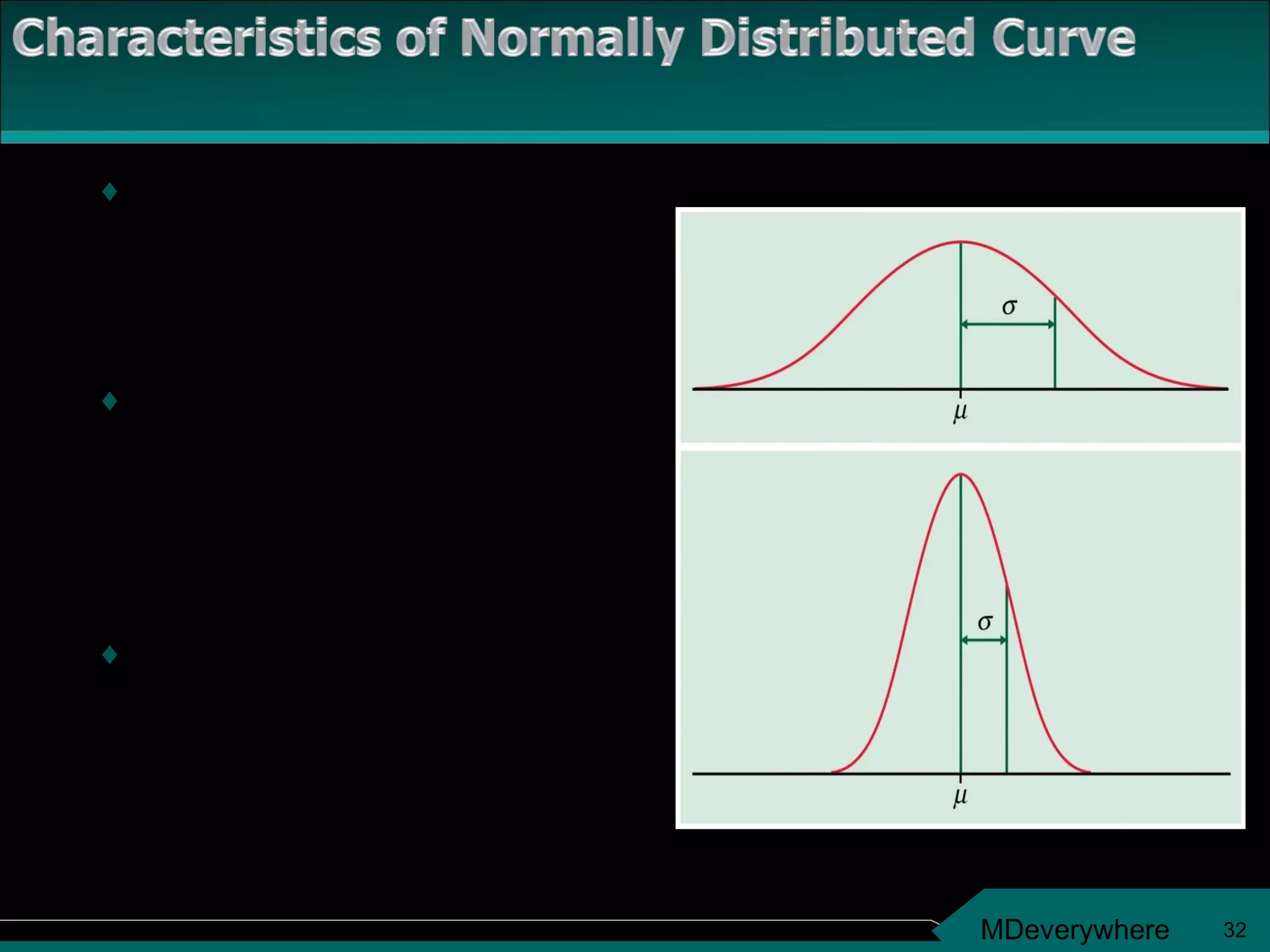

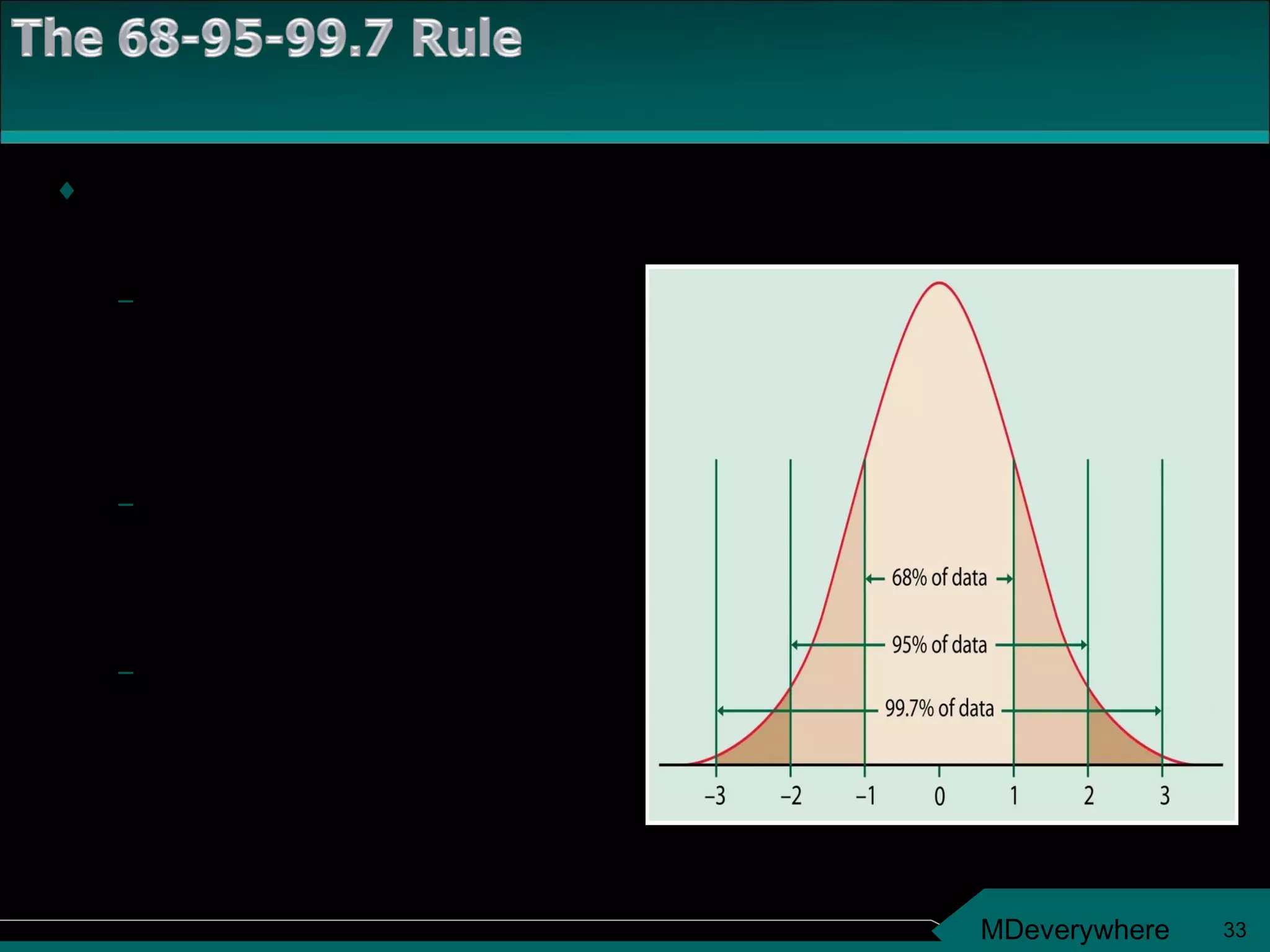

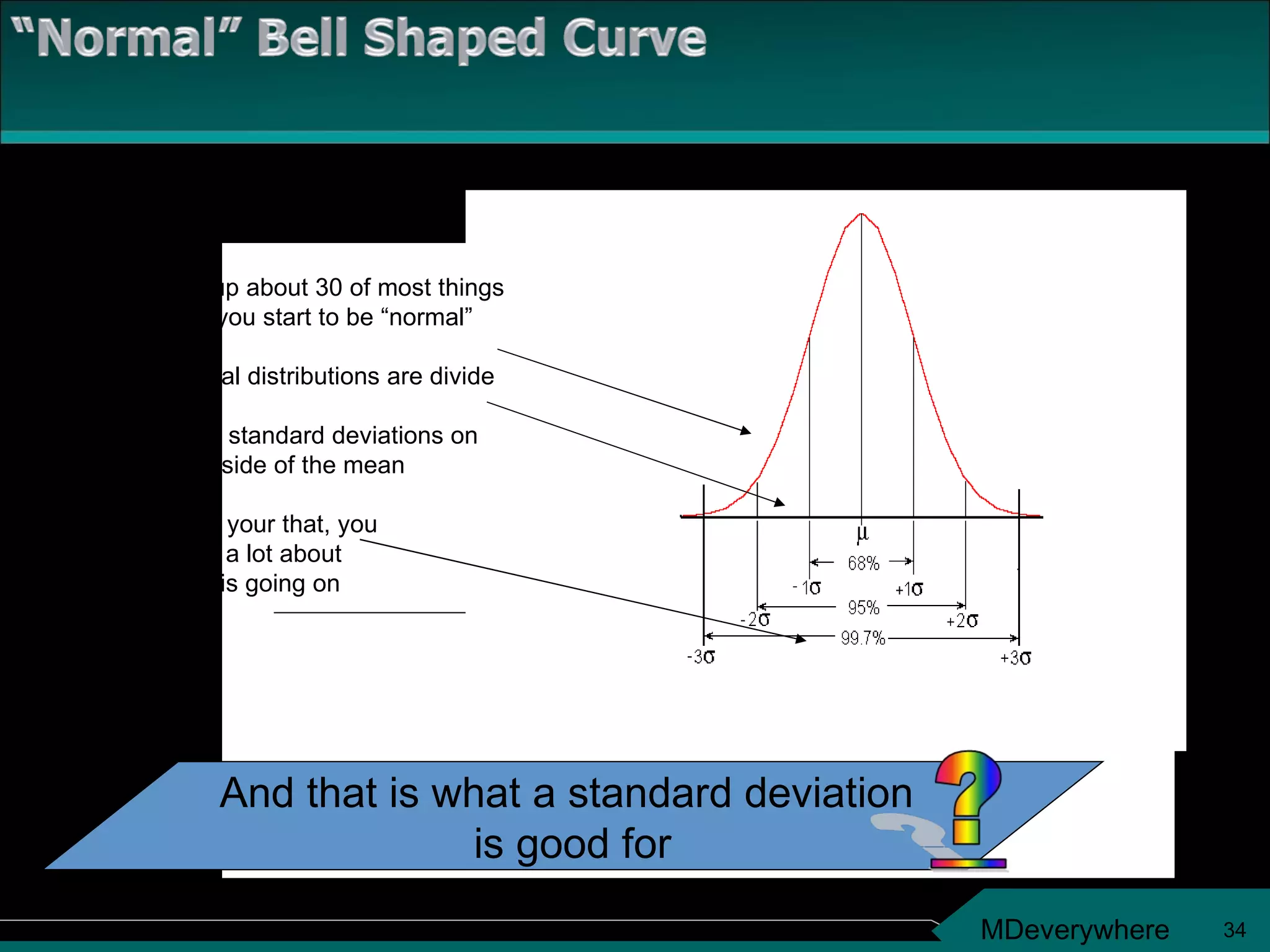

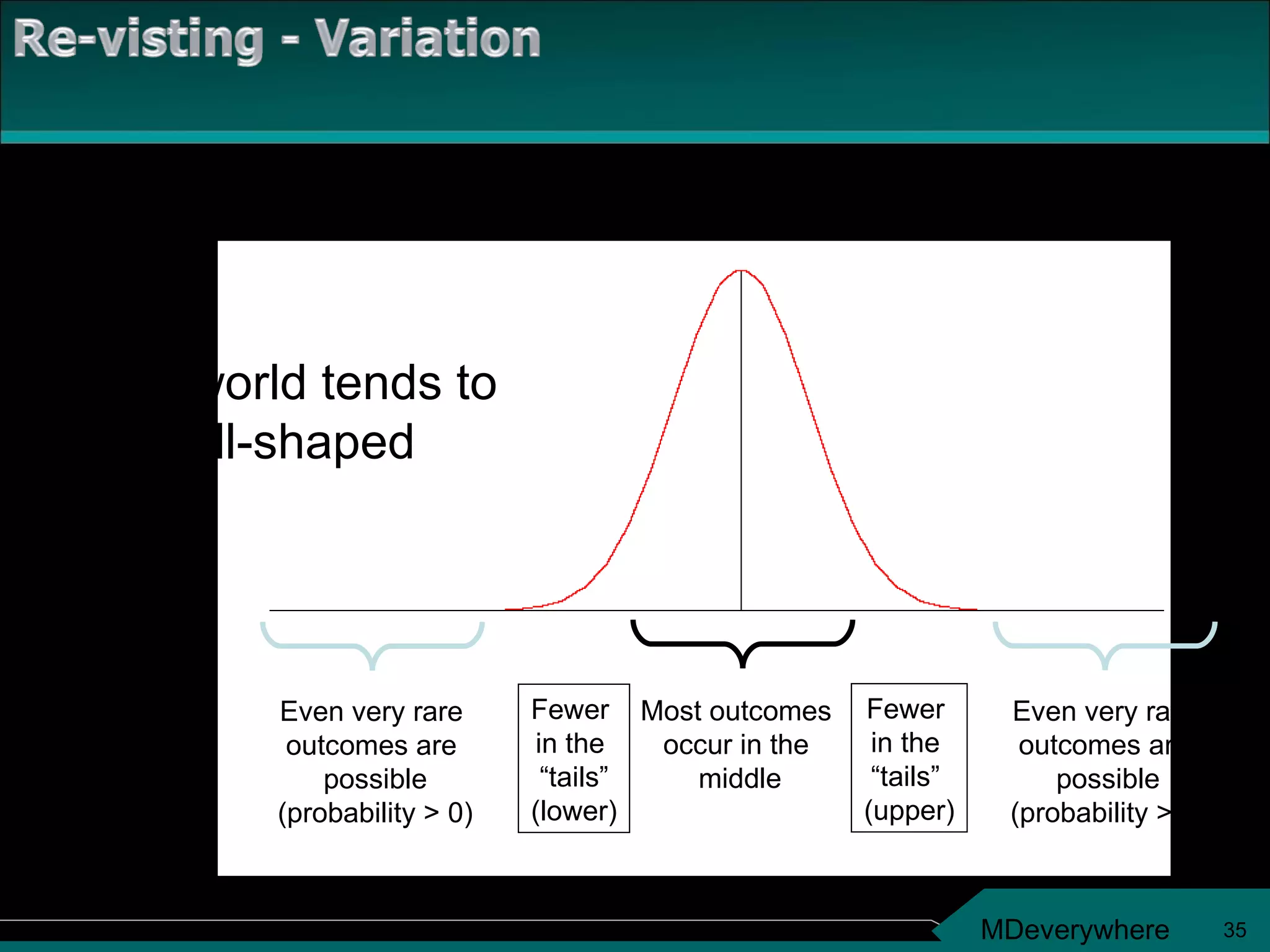

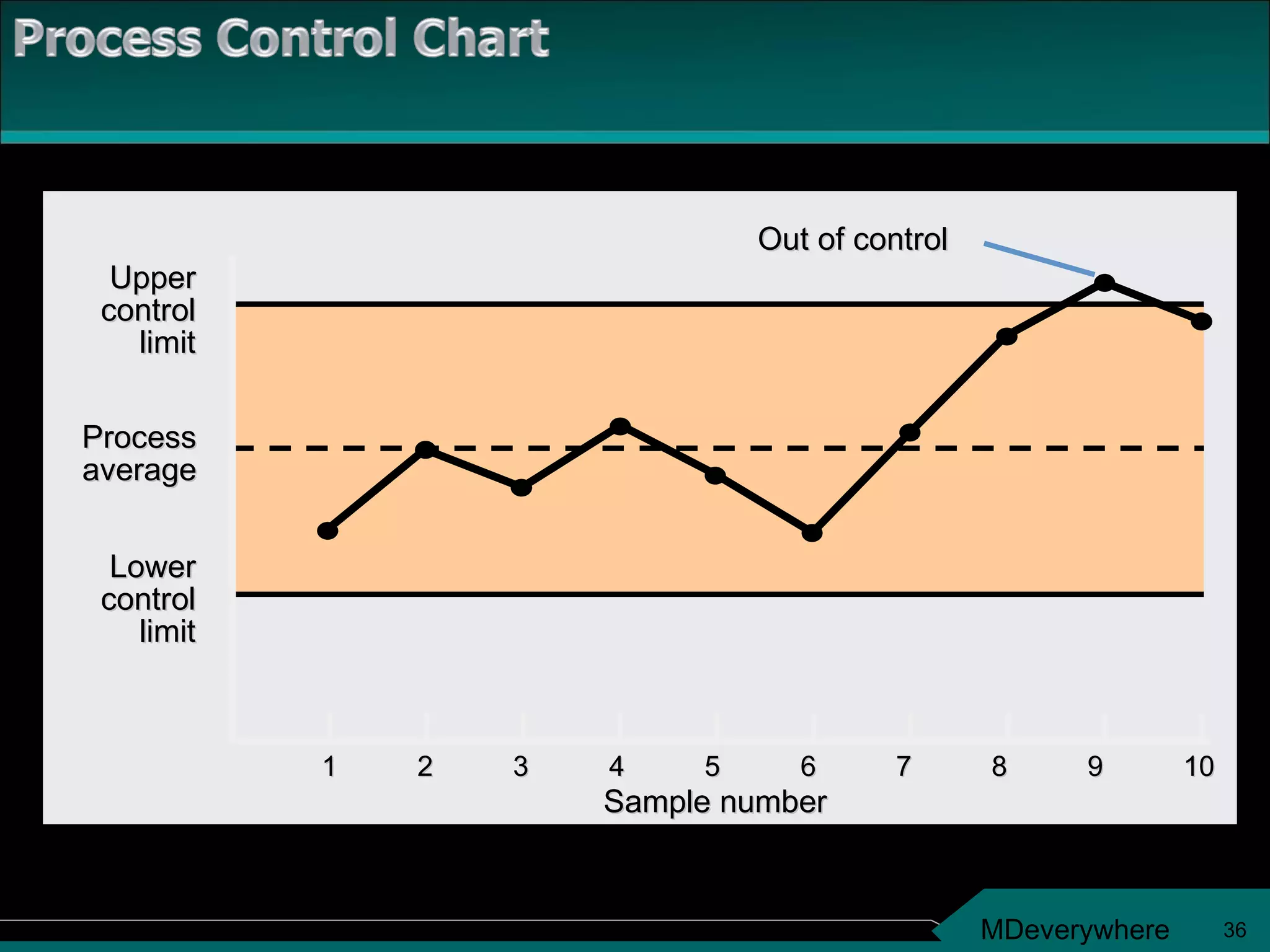

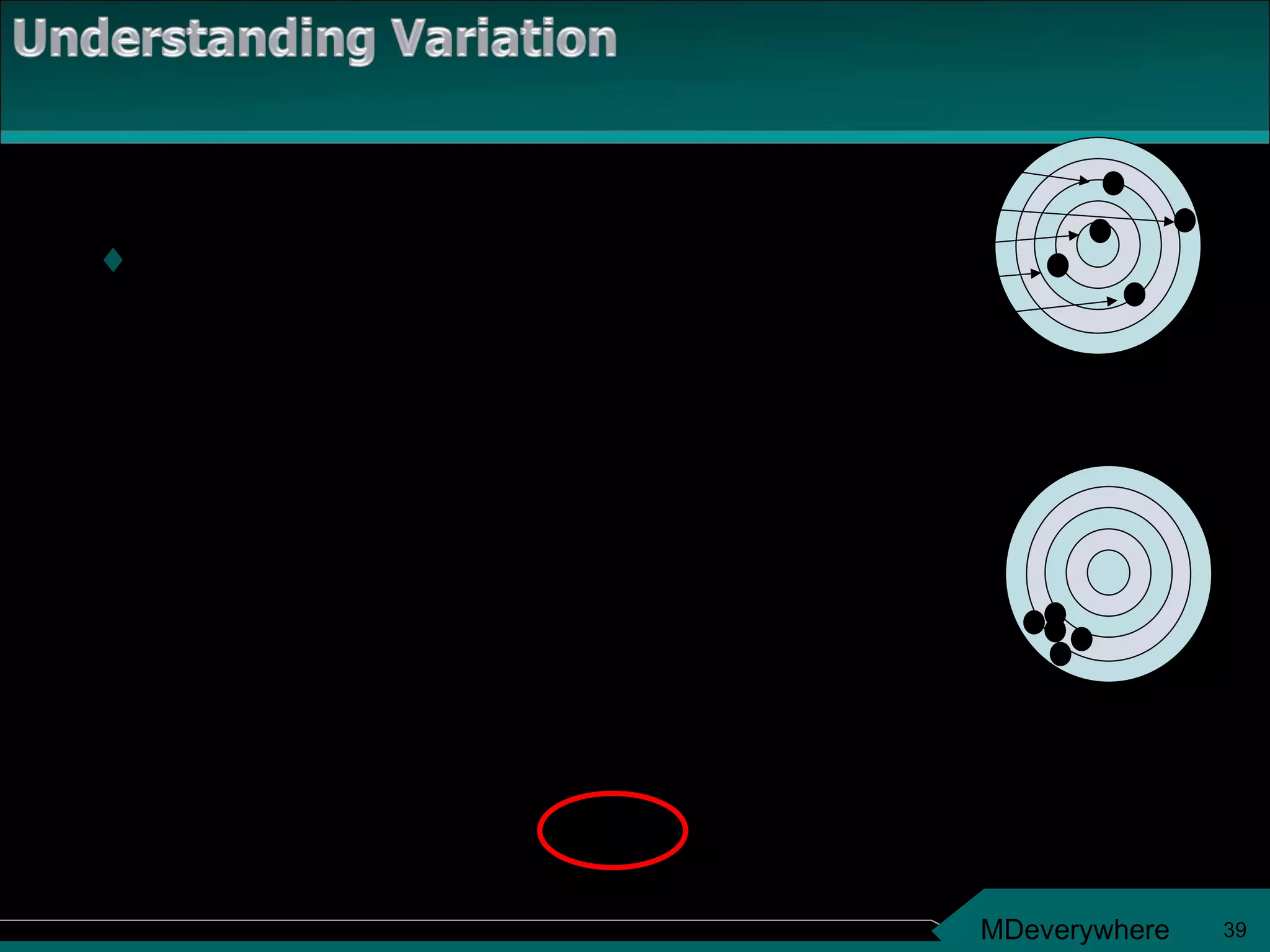

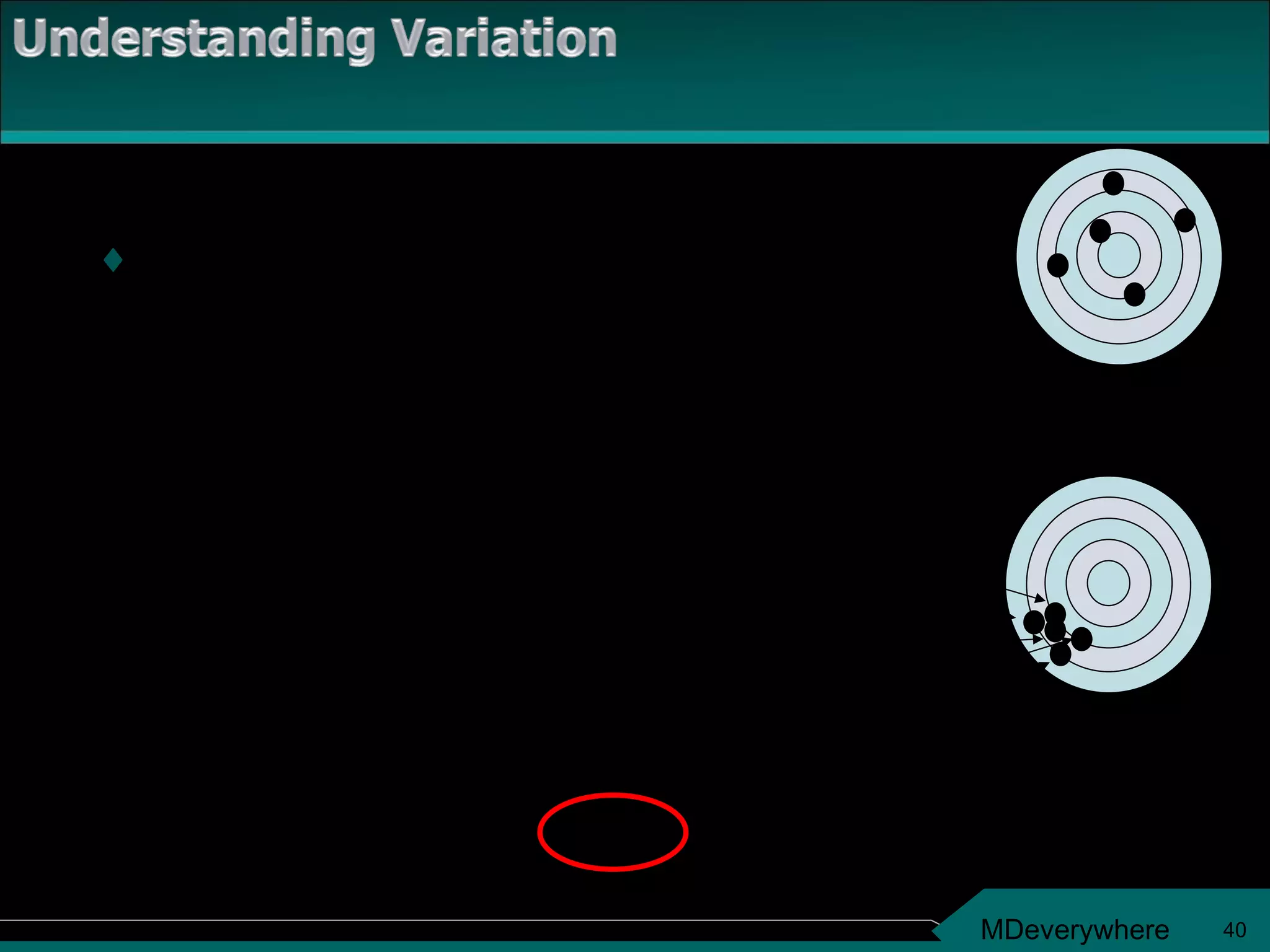

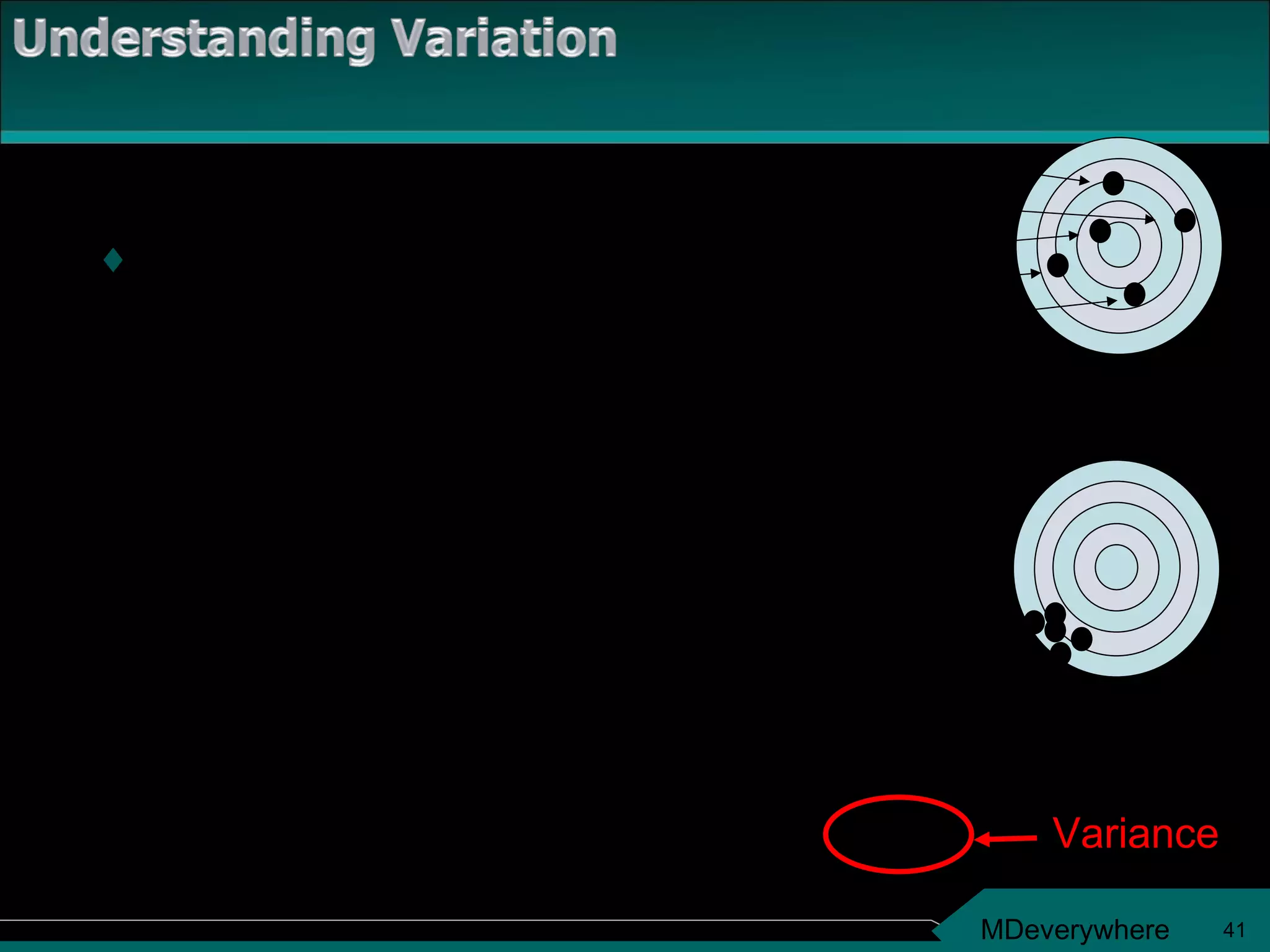

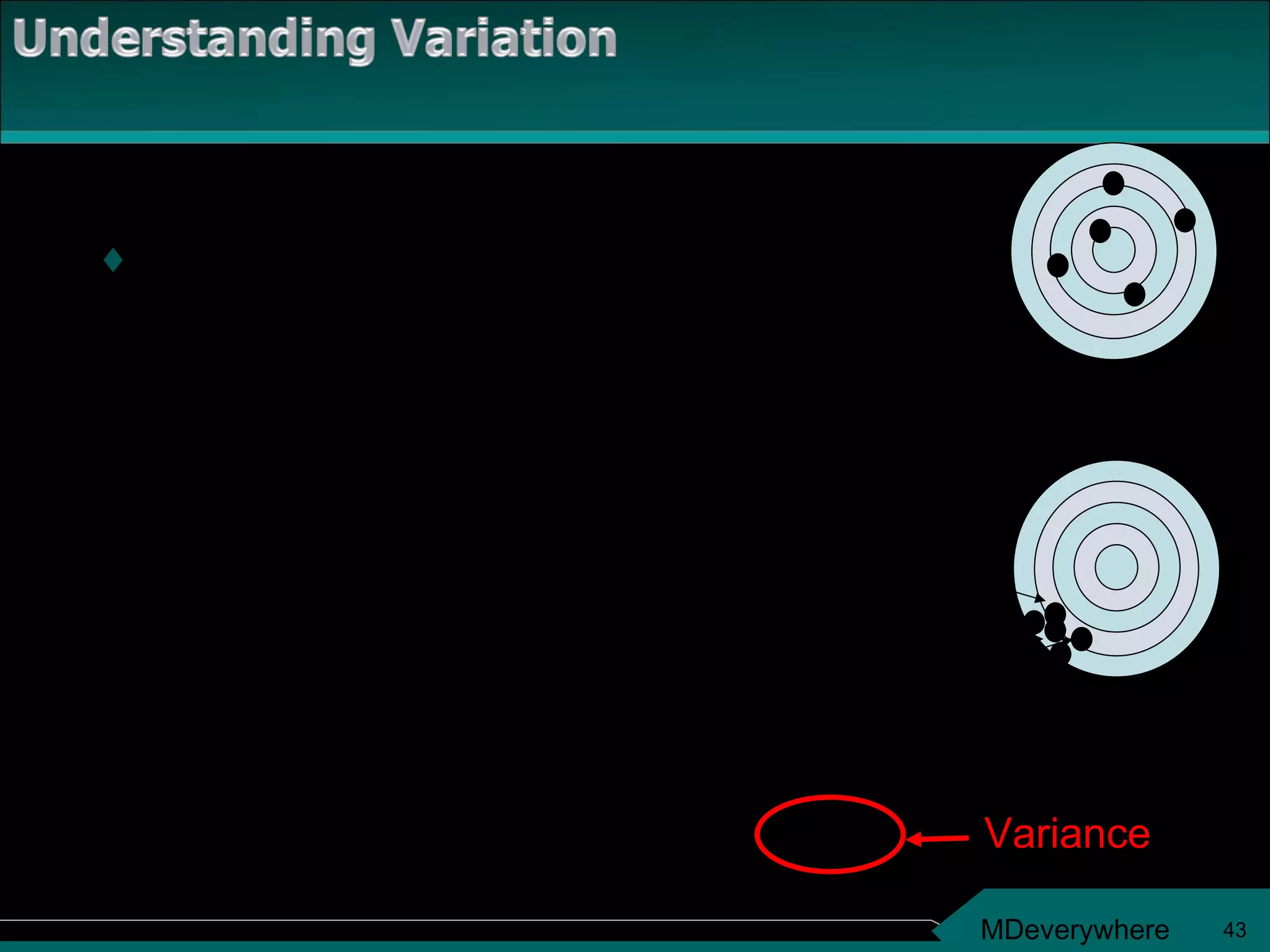

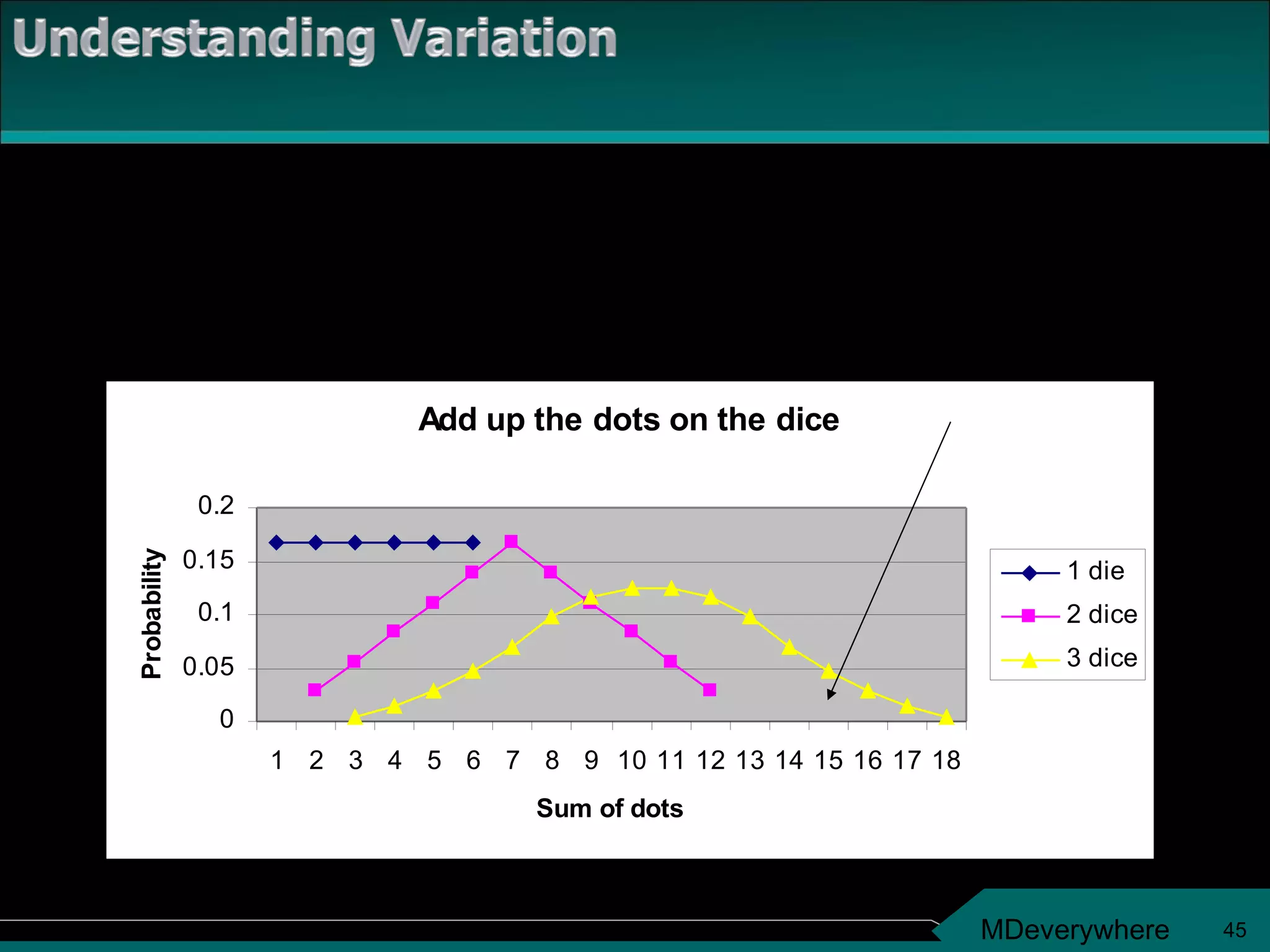

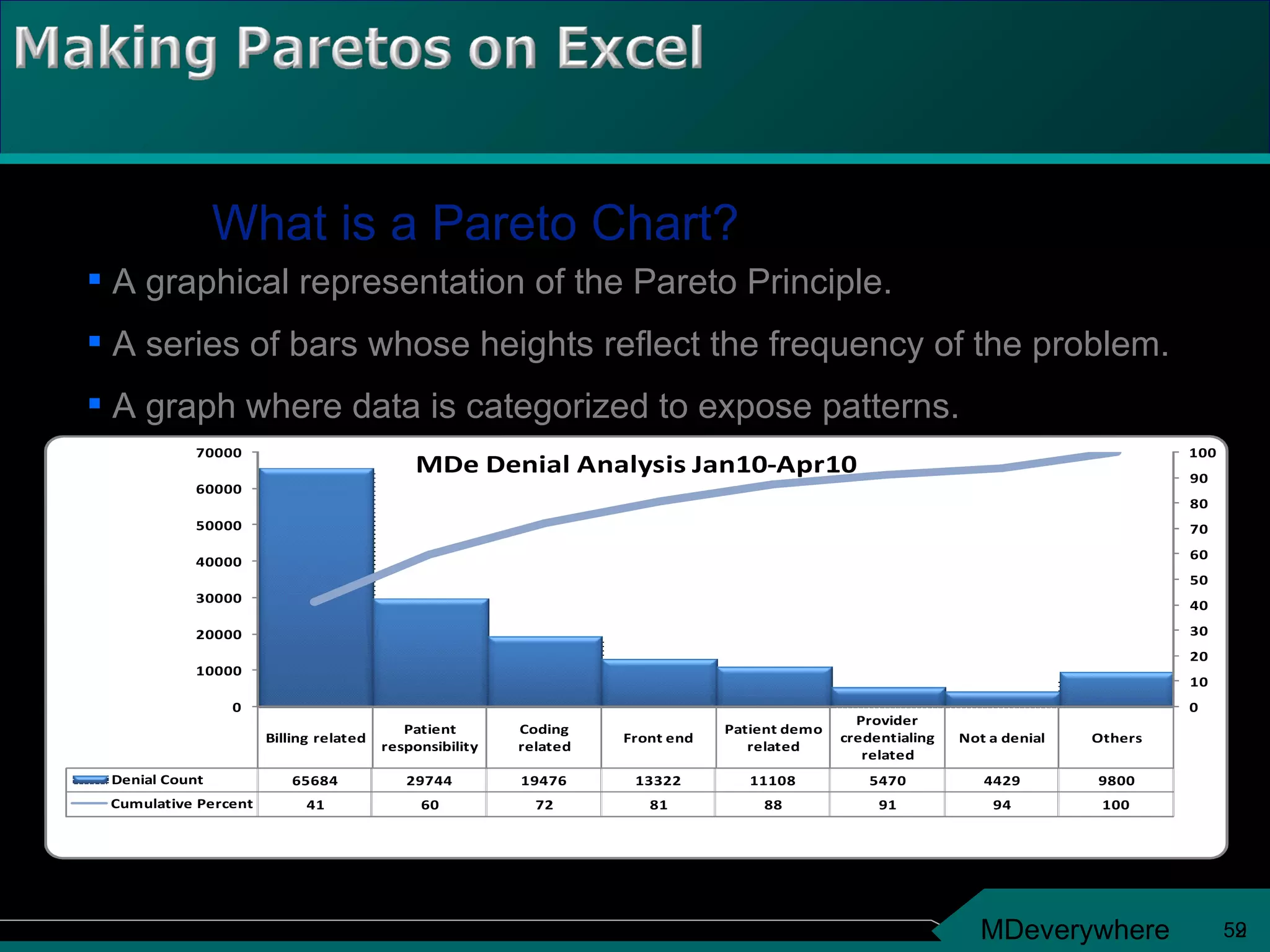

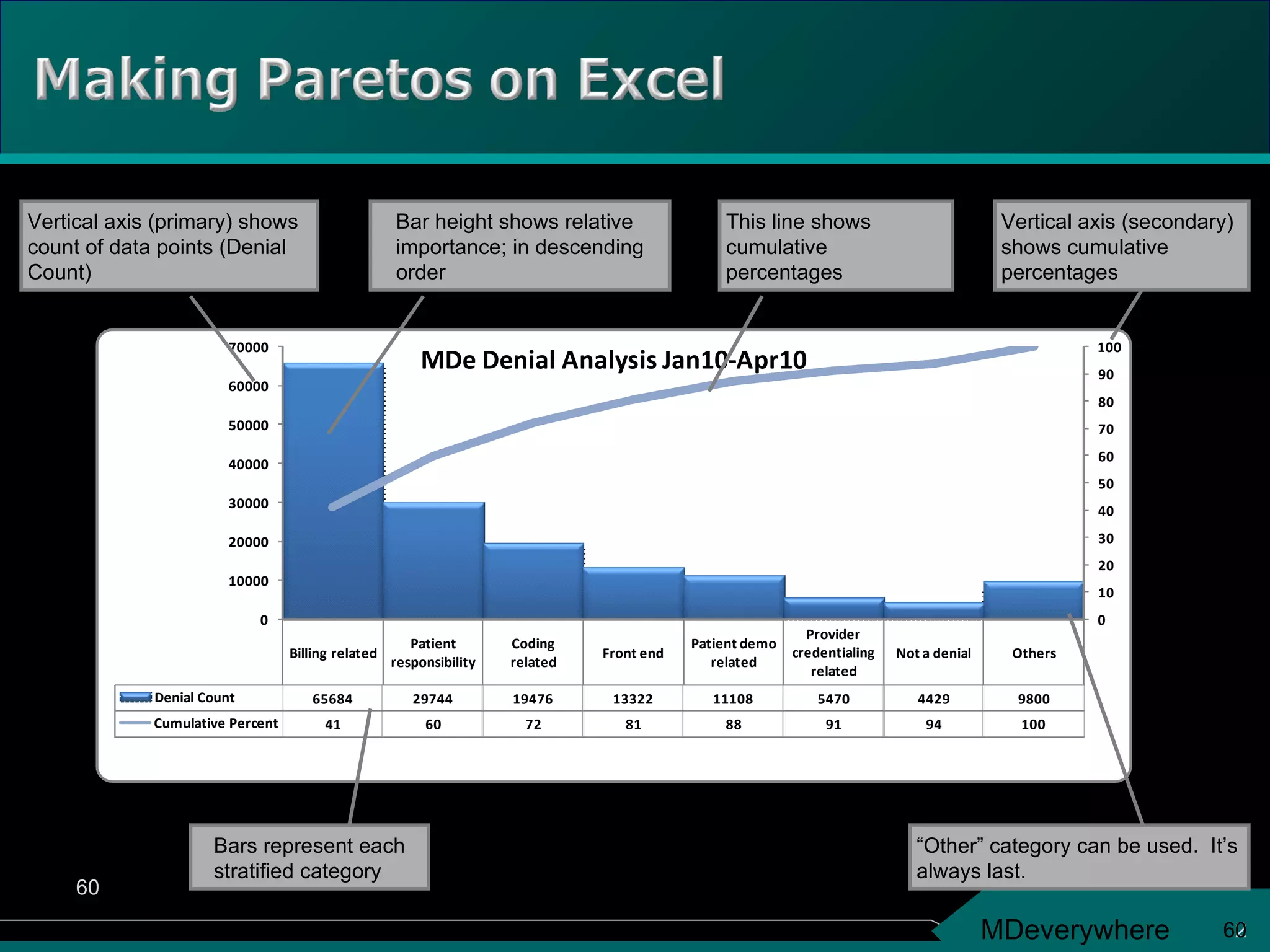

2) It explains key Six Sigma concepts like the DMAIC model, sigma levels, variation, the normal distribution, and the Pareto principle.

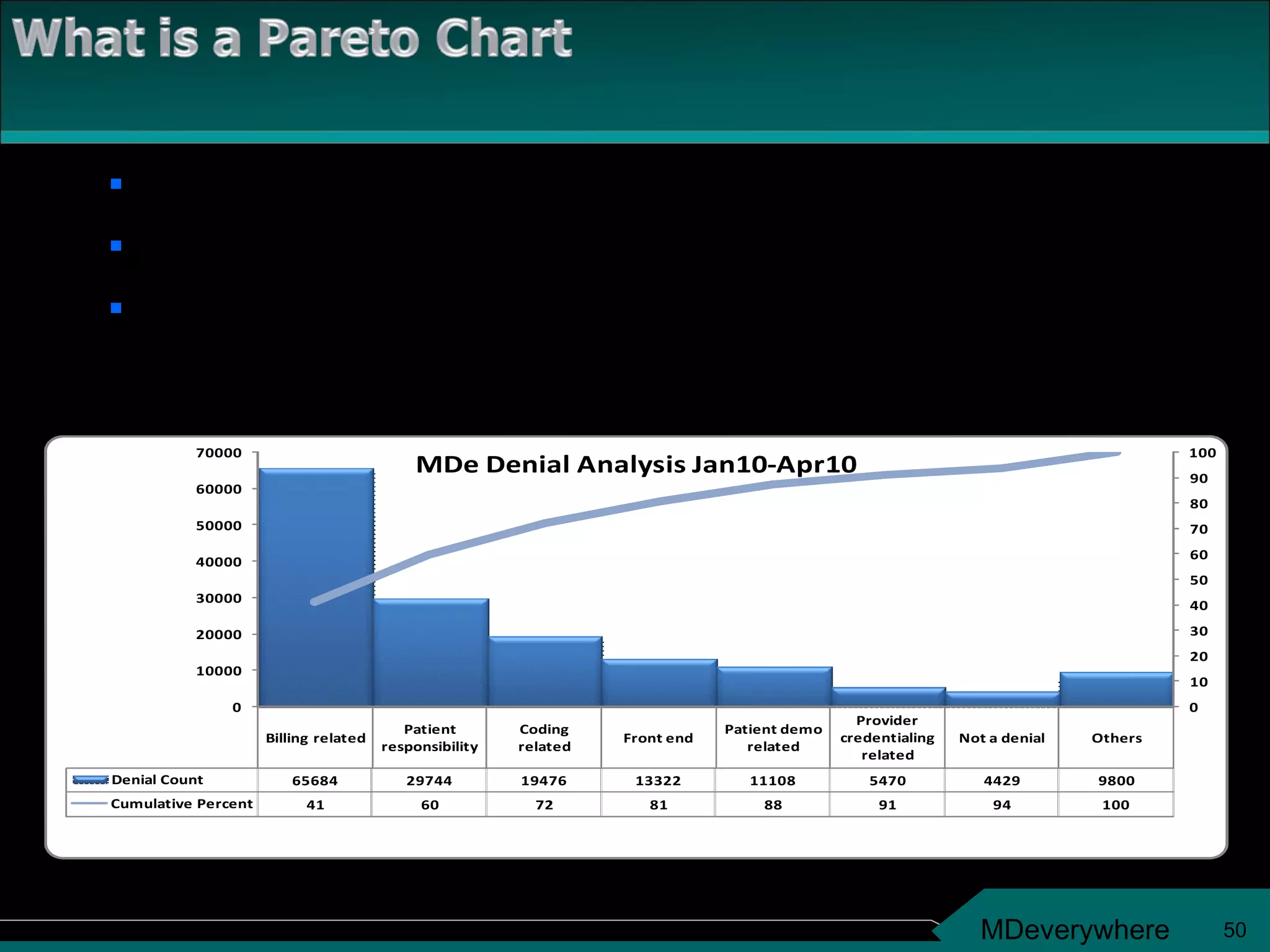

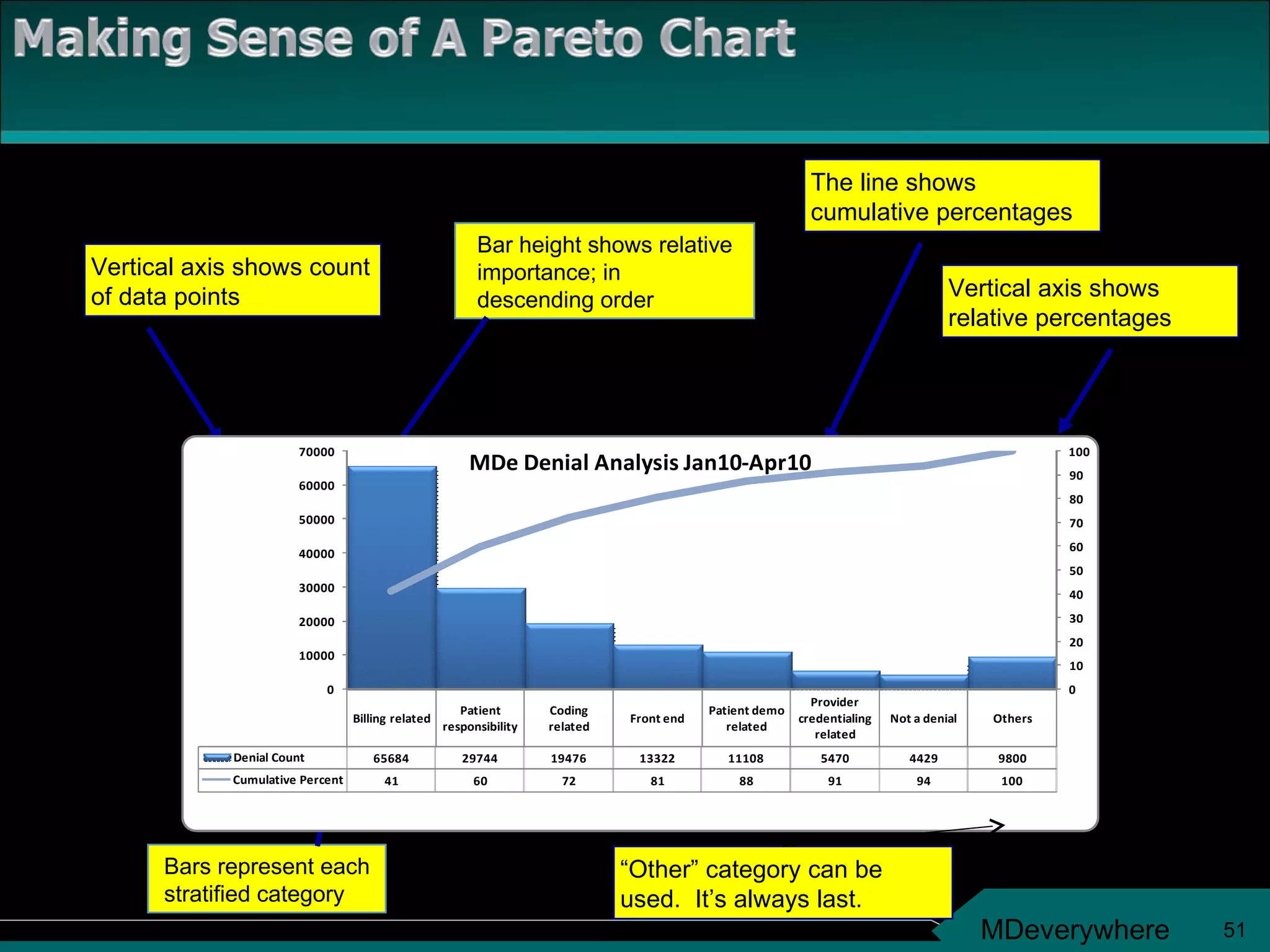

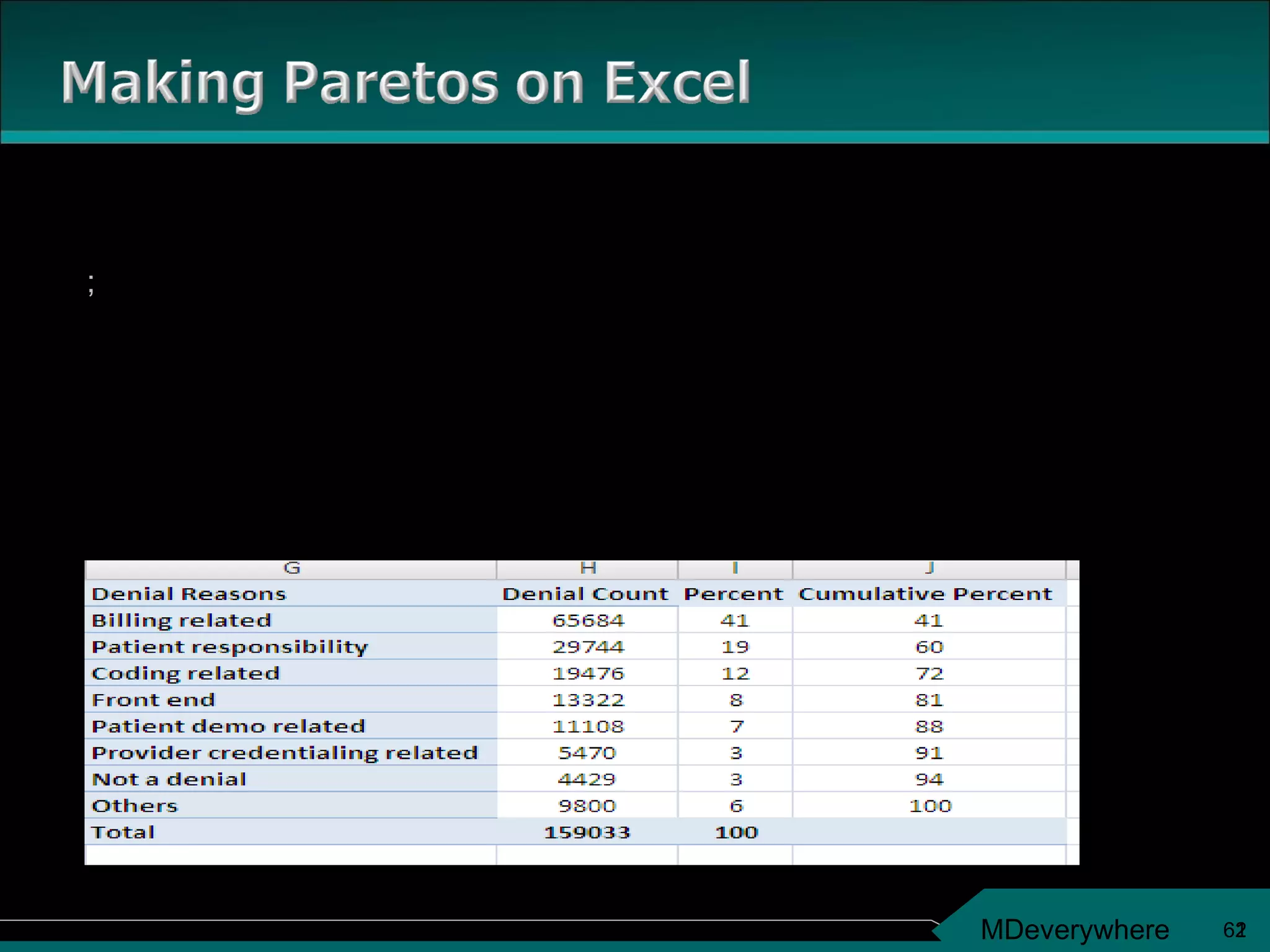

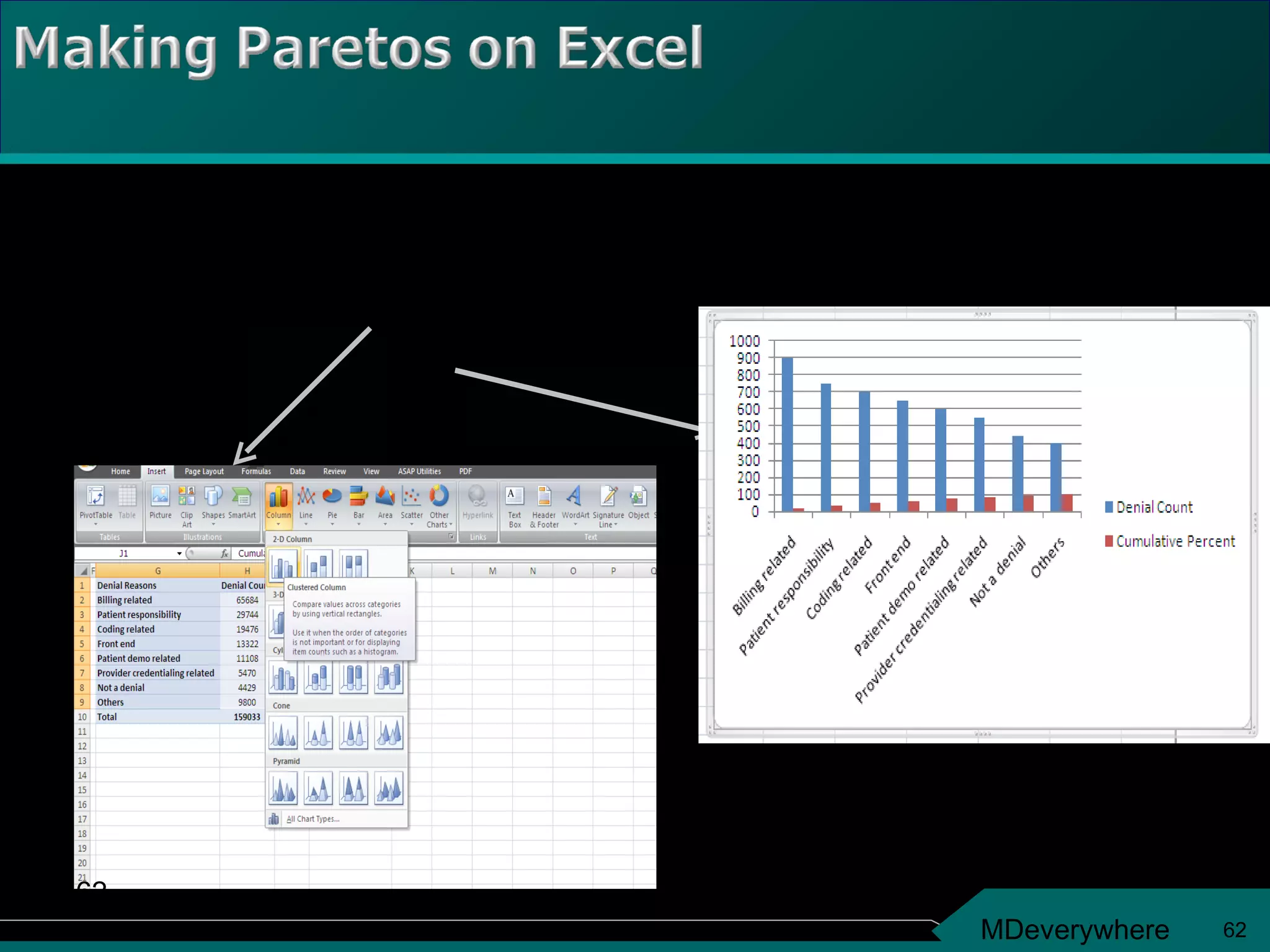

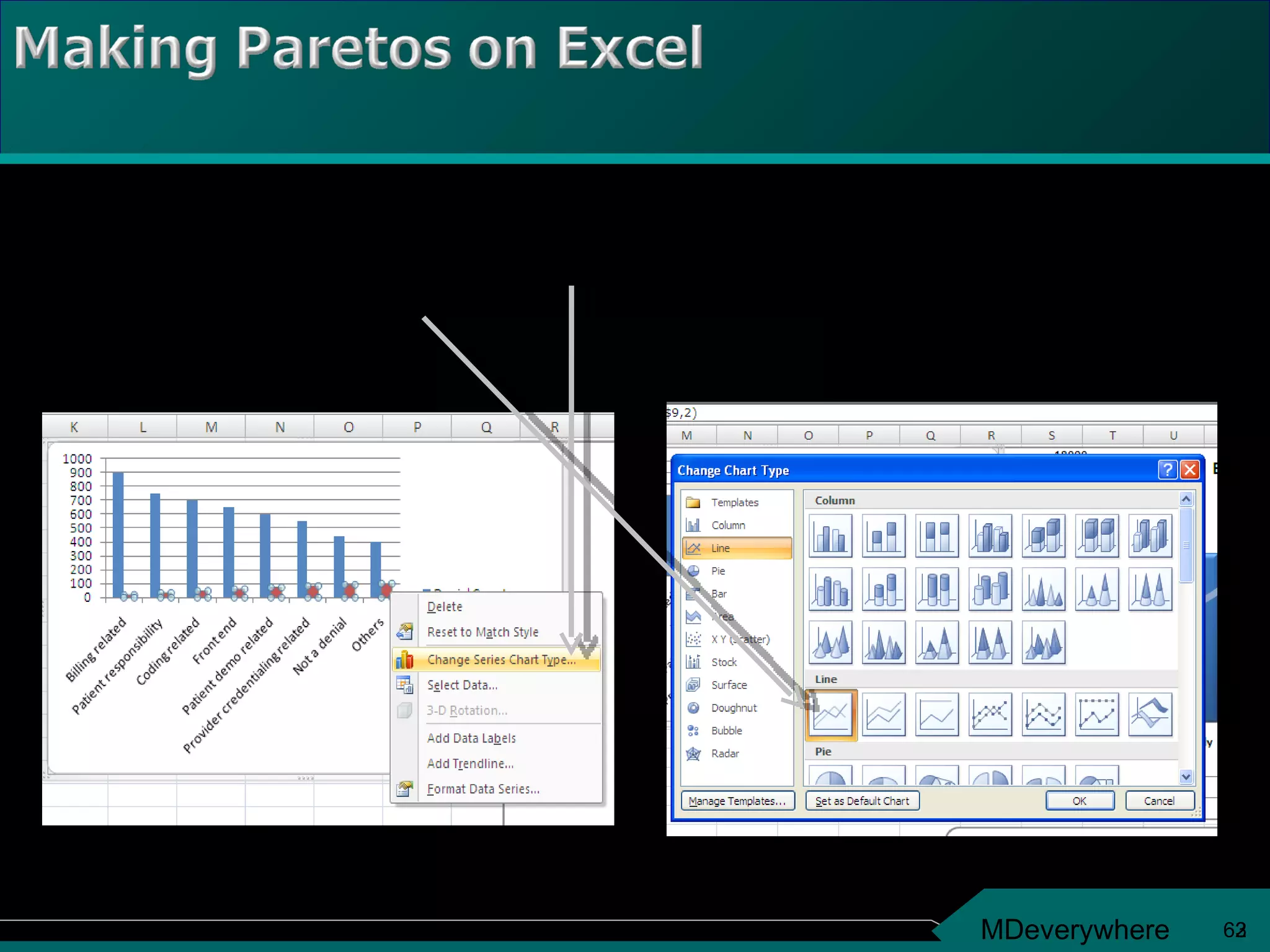

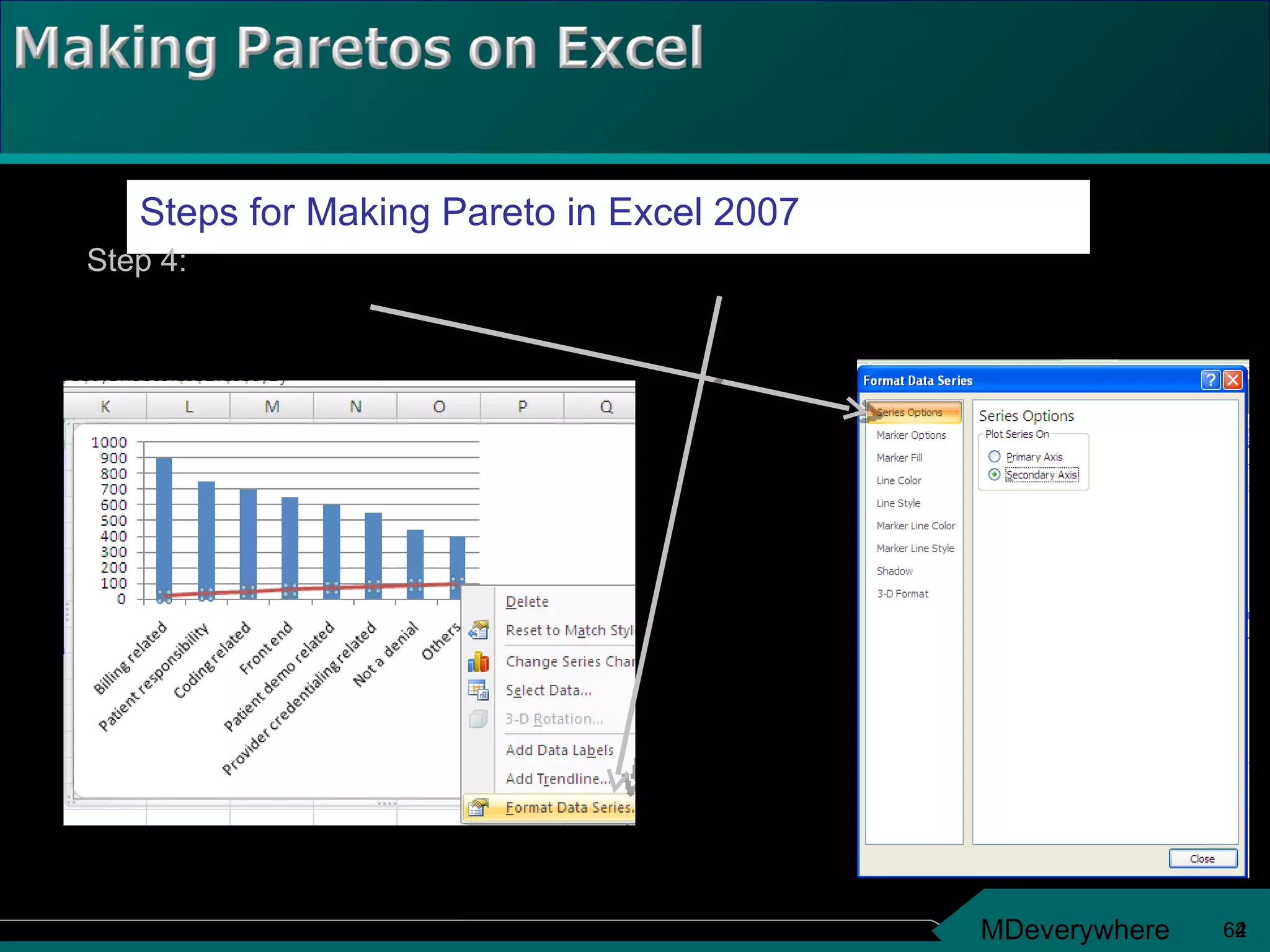

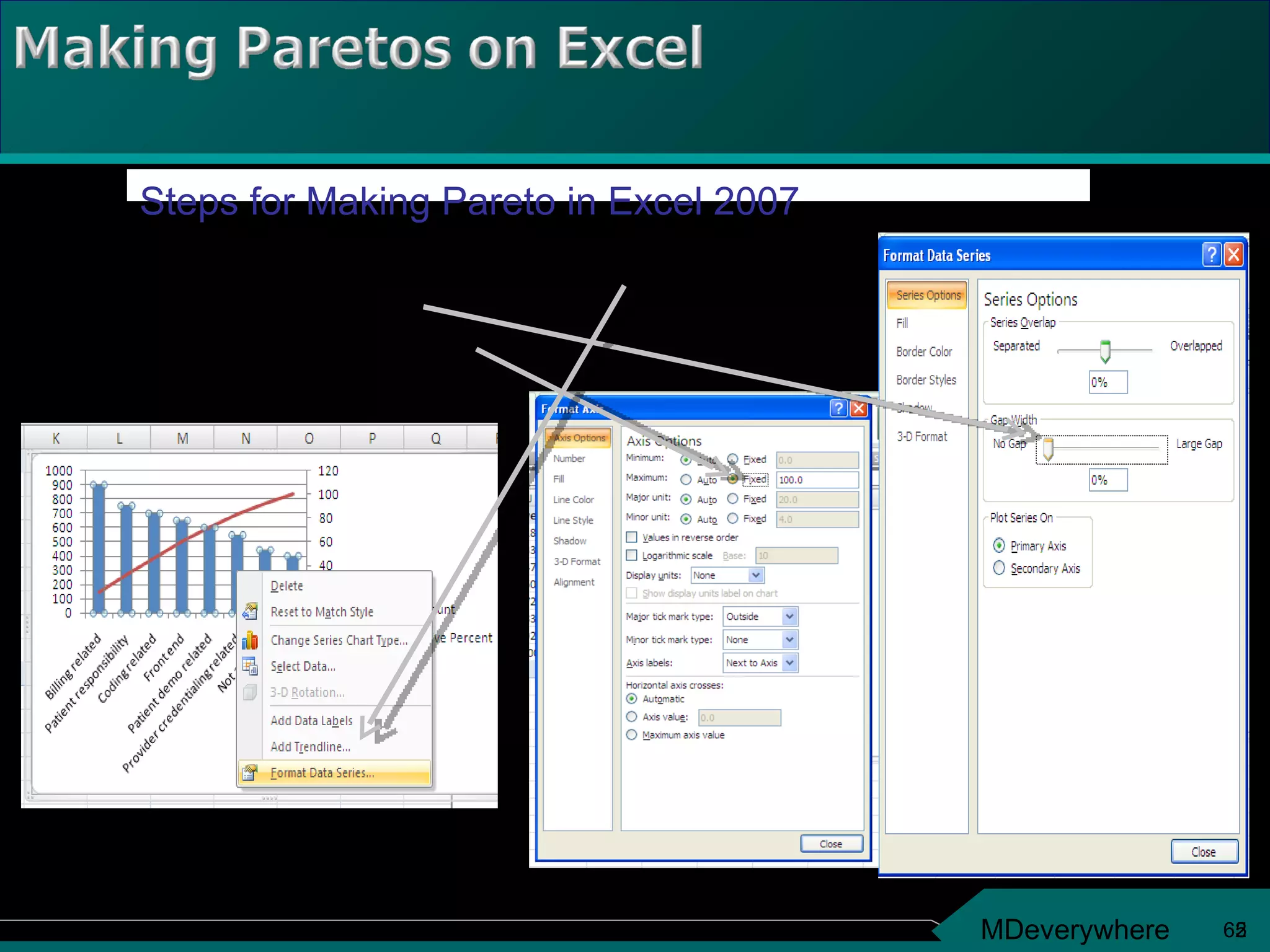

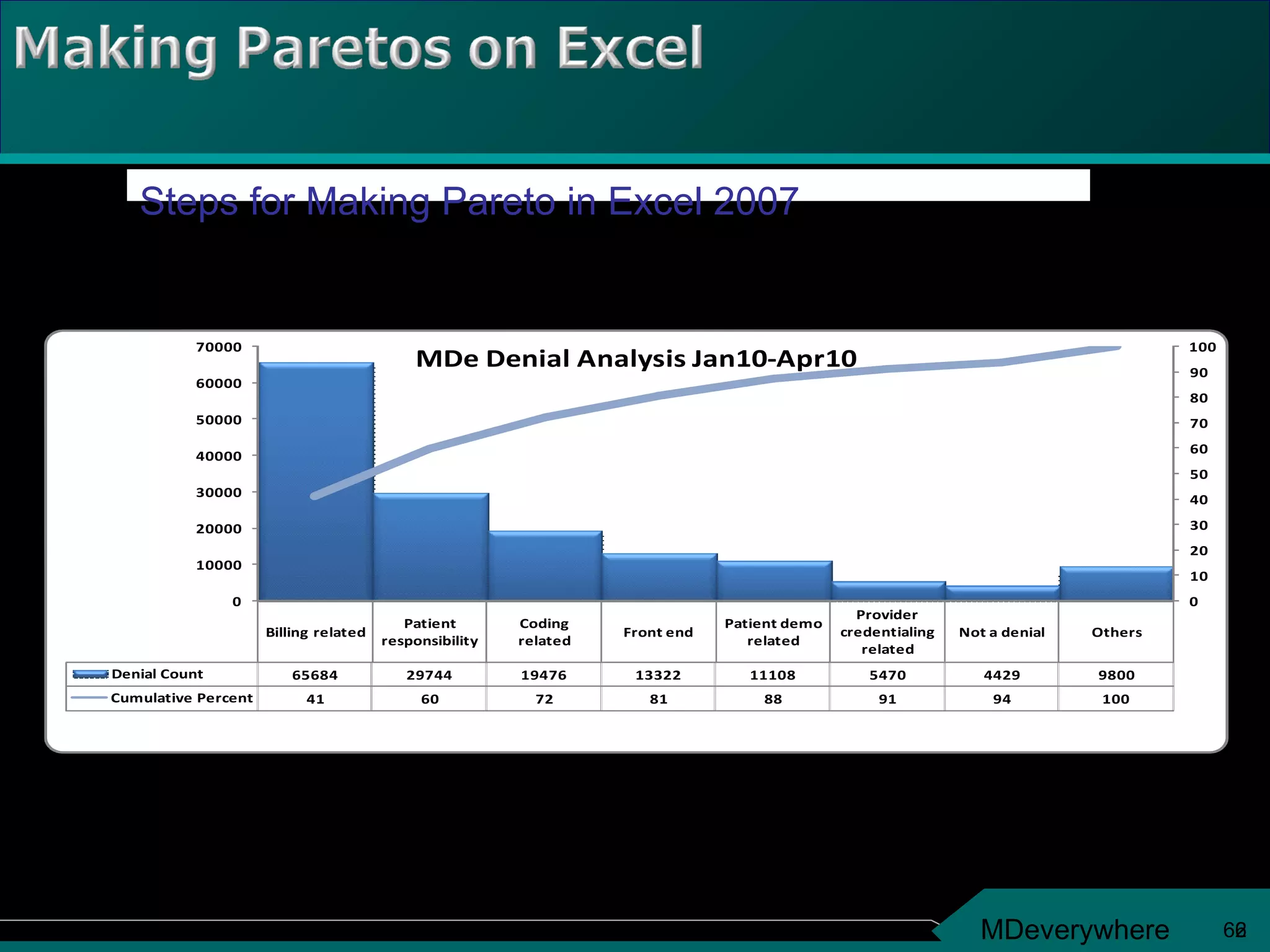

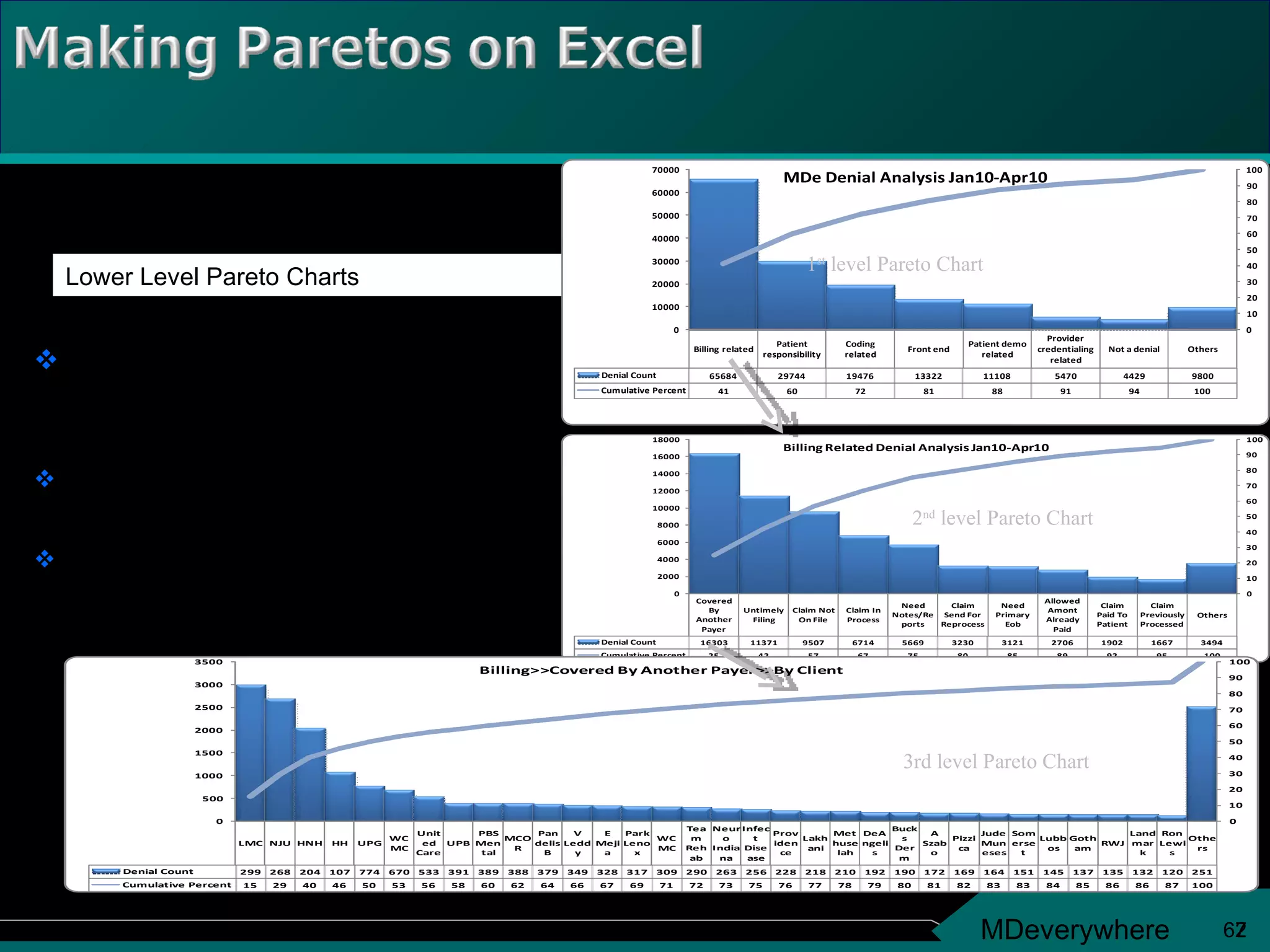

3) It discusses how to create a Pareto chart in Excel to identify the most impactful causes of problems based on frequency of occurrence. Creating lower level charts can help identify root causes.