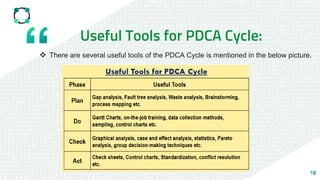

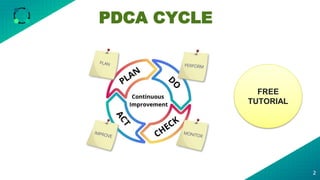

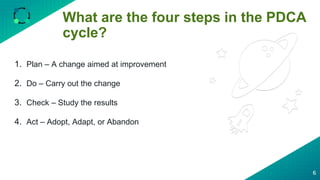

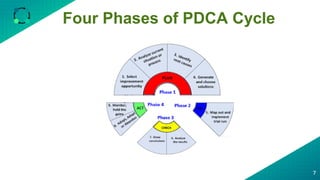

The document discusses the PDCA (Plan-Do-Check-Act) cycle, which is a popular problem-solving and continuous improvement methodology. It describes the four steps of the cycle as Plan, Do, Check, Act. Each step is then further broken down into sub-steps or phases. For example, the Plan step involves selecting an improvement opportunity, analyzing the current situation, identifying root causes, and generating and choosing solutions. The document provides examples and explanations of how to implement each phase of the PDCA cycle for process improvement. It also lists some useful tools that can be used with the PDCA cycle and highlights benefits such as encouraging problem-solving, testing solutions before implementation, and bringing organizations closer to their goals through

![[1] Select Improvement Opportunity:

9

Generate a list and select

Redefine team

Write problem / opportunity / aim statement

Describe the problem

Management review

The team selects the problem to be solved (to be improved)

The problem and objectives are clearly identified

The current situation is analyzed.

Solution alternatives are identified, selected and scheduled](https://image.slidesharecdn.com/pdca-221222095442-4dfef341/85/PDCA-pdf-9-320.jpg)

![[2] Analyze Current Situation:

10

Define the process/problem to be solved

Identify the customer(s).

Prepare Baseline data

Check any Performance gaps are available?

Look at benchmarks, standards, regulatory requirements

Validate problem and statement

Management review](https://image.slidesharecdn.com/pdca-221222095442-4dfef341/85/PDCA-pdf-10-320.jpg)

![[3] Identify Root Causes:

11

This is a very very important step

Utilize the Cause and Effect Diagram (Fishbone Diagram or Ishikawa Diagram, or Why-

Why analysis to identify the most likely cause(s).

Use Genchi Gembutsu Method

Select root cause

Management review](https://image.slidesharecdn.com/pdca-221222095442-4dfef341/85/PDCA-pdf-11-320.jpg)

![[4] Generate and Choose Solutions:

12

Generate a list and select solutions

Directly linked to root cause & supported by data

Team brainstorming and shared decision making

Be honest about barriers

Choose the best solution based on criteria

Define and map out a solution

Develop solution(s) to remove the root cause(s)

Select the best solution(s) to remove the root cause(s)

Verify that effectiveness of the selected solutions

Verify that selected solutions do not cause any undesirable effects

Set a Target that you want to achieve](https://image.slidesharecdn.com/pdca-221222095442-4dfef341/85/PDCA-pdf-12-320.jpg)

![Implementation of Do Phase:

[5] Map Out and Implement a Trial Run:

13

Map out a trial run

Communication and education/training are key factors

Be specific

Implement a trial run

Ensure all the countermeasures are completed

It involves collecting data for later analysis

It ensures the solution is appropriately tested

Implementation of Check Phase:

The check phase has two sub-phases which are mentioned below.

6. Analyze the Results

7. Draw Conclusions](https://image.slidesharecdn.com/pdca-221222095442-4dfef341/85/PDCA-pdf-13-320.jpg)

![[6] Analyze the Results:

14

Evaluate results based on collected data

Team-based analysis

Objective and subjective data

Revisit the process as it was mapped out

Be honest!

Evaluate both Results and Process

Involves analyzing the collected data and comparing the actual results against the

planned objectives.

Allows discussing whether further improvements are possible

You may have to repeat the Do and Check a number of times until you get the optimum

results](https://image.slidesharecdn.com/pdca-221222095442-4dfef341/85/PDCA-pdf-14-320.jpg)

![[7] Draw Conclusions:

15

Team-based discussion

Was the root cause eliminated?

What worked?

Did the desired change occur?

What didn’t work?

What could be improved/changed?

Implement the best solution(s) to remove the root cause(s)

What did we learn?

Implement the best solution(s) to address the escape point(s)

Validate the effectiveness of the implemented solutions by Customer's perspective

Monitor the effectiveness of the implemented solutions and assure that they do not

cause any undesirable effects

Remove Interim Containment Actions

Implementation of Act Phase:

The last phase is the act phase and it has two sub-phases as mentioned below.

8. Adopt, Adapt, or Abandon the Intervention

9. Monitor; Hold the gains](https://image.slidesharecdn.com/pdca-221222095442-4dfef341/85/PDCA-pdf-15-320.jpg)

![[8] Adopt, Adapt, or Abandon the

Intervention:

16

Team-based discussion and beyond

Test again on a larger scale?

Communication, education, and training

Revise plan and repeat trial

Communication, education, and training

Revisit root cause analysis and/or list of solutions

Need additional/new members on the team?

Involves acting on the feedback and lessons learned and implementing the solution

It is also concerned with: Standardizing, Documenting, Sustaining the improved

process

Integrating it into the organization’s system.](https://image.slidesharecdn.com/pdca-221222095442-4dfef341/85/PDCA-pdf-16-320.jpg)

![[9] Monitor; Hold the gains:

17

Standardize the change

Change to department policy?

Continue to monitor improvement

Same data collection tools and process

Continue reporting to staff and management

Move to new improvement opportunity

Standardize Success and Learn from Failures](https://image.slidesharecdn.com/pdca-221222095442-4dfef341/85/PDCA-pdf-17-320.jpg)