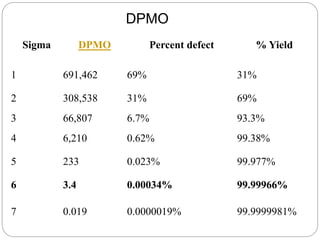

Six Sigma is a set of tools and strategies originally developed by Motorola to improve processes and minimize defects. It aims for nearly flawless processes, with 99.99966% defect-free products. Six Sigma seeks to identify and remove causes of defects through statistical methods and process improvement projects. It establishes experts like Black Belts to lead projects following methods like DMAIC to Define, Measure, Analyze, Improve, and Control processes. The goal is quantifiable financial returns through reducing variation and defects in manufacturing and business operations.

![Features

A clear focus on achieving measurable and

quantifiable financial returns from any Six Sigma

project.[5]

An increased emphasis on strong and passionate

management leadership and support.[5]

A special infrastructure of "Champions", "Master

Black Belts", "Black Belts", "Green Belts", etc. to

lead and implement the Six Sigma approach.[5]

A clear commitment to making decisions on the

basis of verifiable data and statistical methods,

rather than assumptions and guesswork.[5]](https://image.slidesharecdn.com/lec9-sixsigma-160806151330/85/six-sigma-in-supply-chain-management-7-320.jpg)