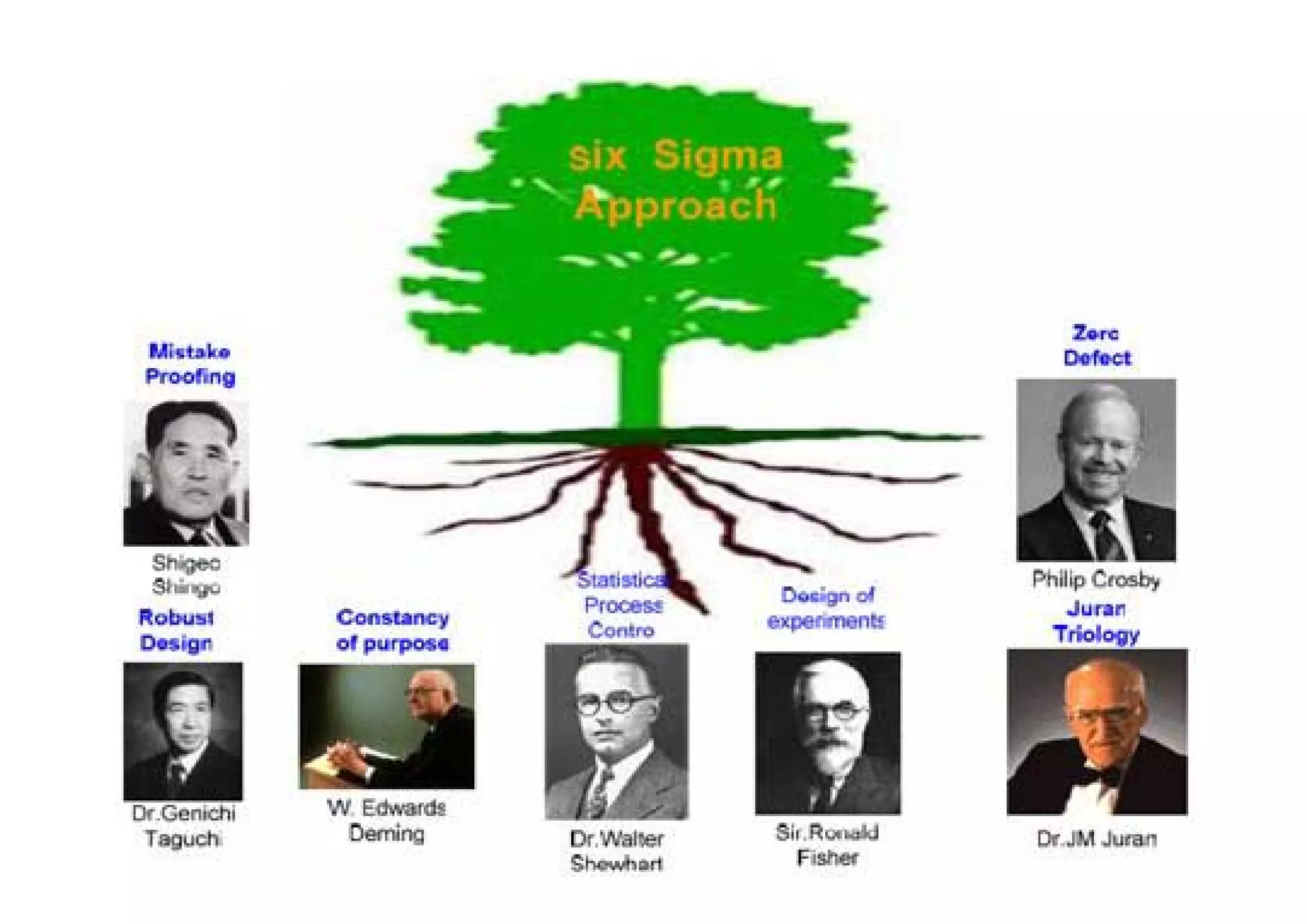

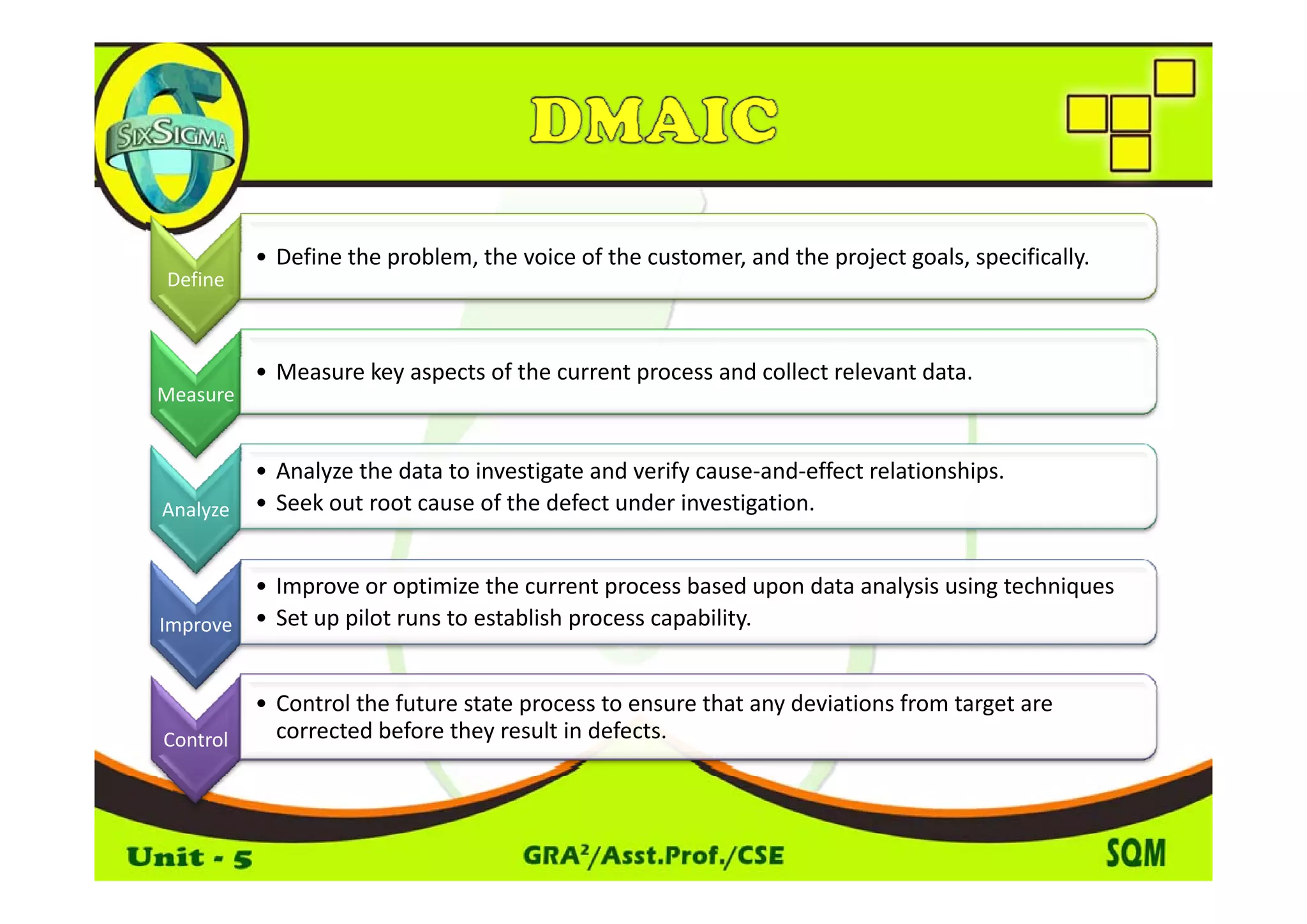

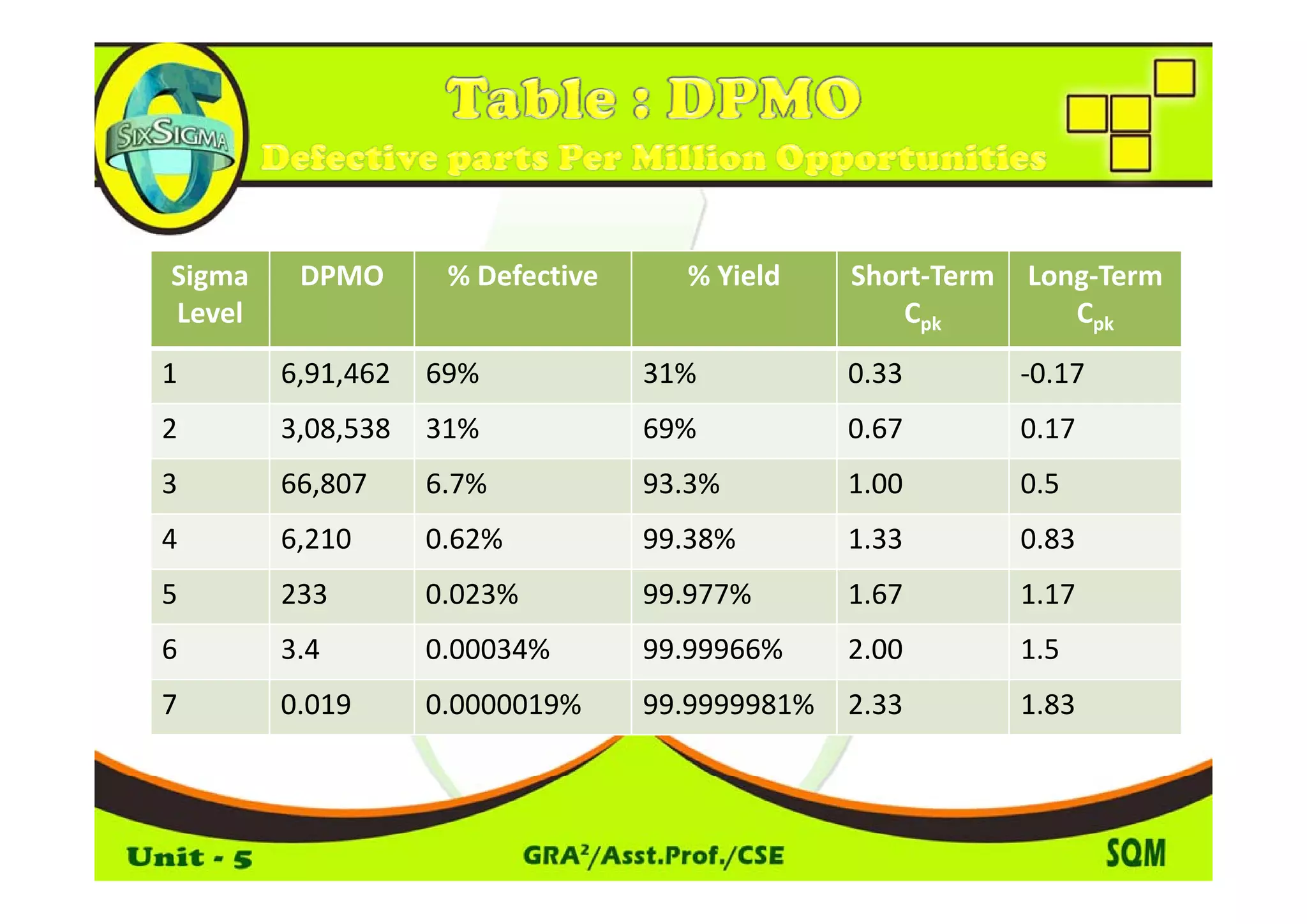

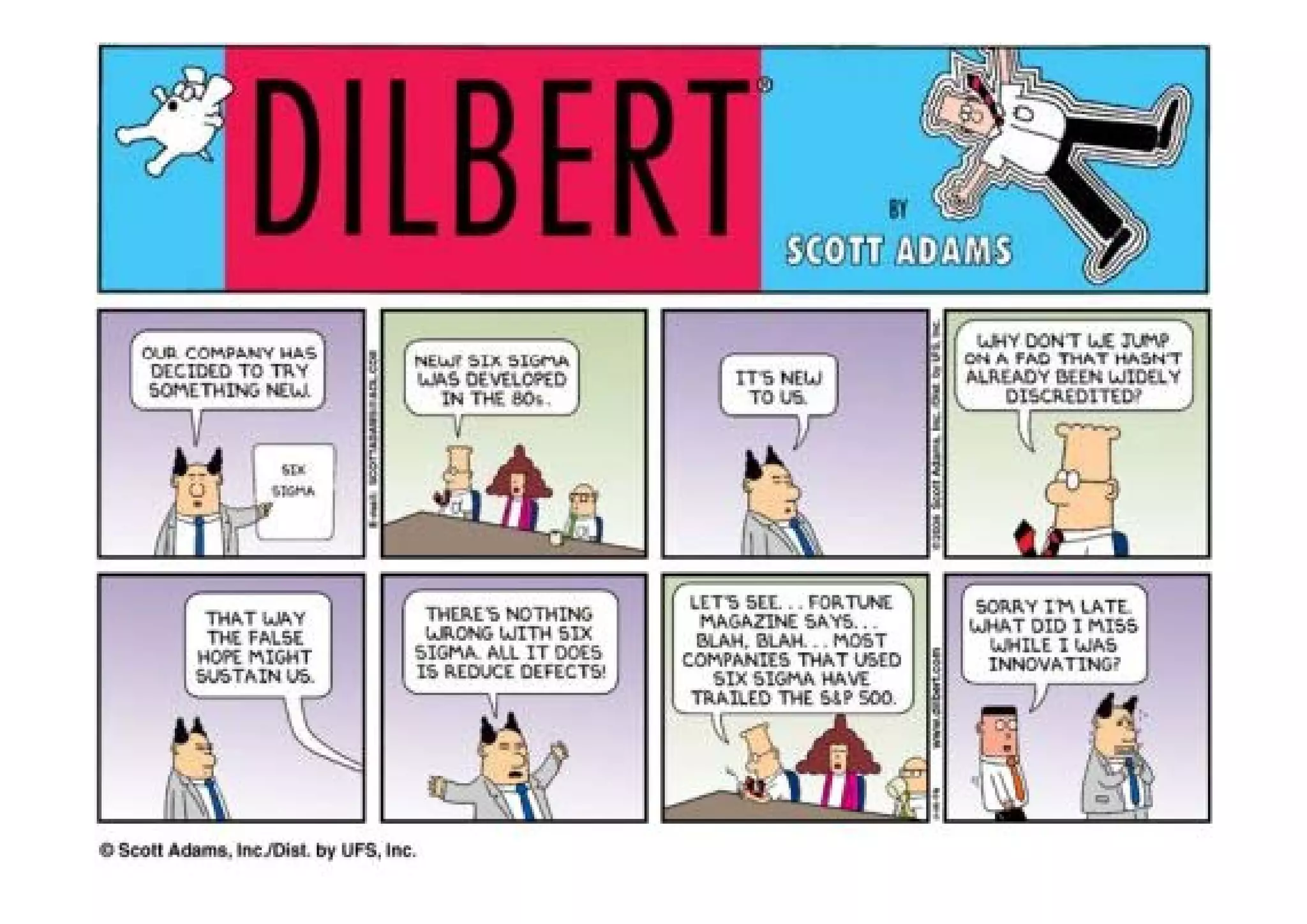

Six Sigma is a business management strategy originally developed by Bill Smith at Motorola in 1986 to improve processes and minimize defects. It aims for near perfect processes, with 99.99966% defect-free products or 3.4 defects per million opportunities. Six Sigma identifies roles like Champions, Master Black Belts, Black Belts, and Green Belts to lead projects using DMAIC or DMADV methodologies. While effective for process improvement, critics argue Six Sigma may lack originality, oversell consulting services, and focus narrowly on existing processes rather than innovation. Some also question its arbitrary standards and assumptions about normal distributions.