1) The document summarizes a site visit report to a construction site of two apartment blocks and a serviced apartment.

2) During the visit, students observed various construction materials, processes and equipment used at the site including formwork, scaffolding, concrete and safety practices.

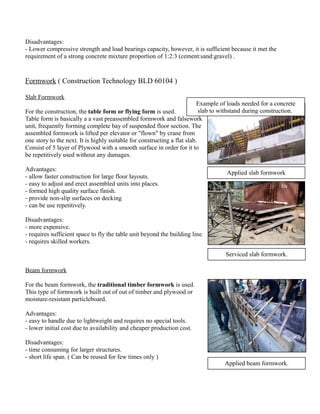

3) Key areas discussed included the types of formwork used for slabs, beams and columns, the use of independent scaffolding outside and inside the building, and details on the grade of concrete poured.

![SCHOOL OF ARCHITECTURE, BUILDING & DESIGN

Bachelor of Quantity Surveying (Honours)

MEASUREMENT 1 [QSB 60104]

CONSTRUCTION TECHNOLOGY I [BLD 60104]

BUILDING MATERIALS [BLD 62003]

Title : Site Visit To D’Latour Construction Site Report

Name : Muhammad Hasif bin Alias

Student ID : 0316413](https://image.slidesharecdn.com/finalassignment-141203120823-conversion-gate01/85/BQS-Site-Visit-Report-1-320.jpg)