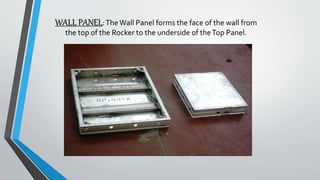

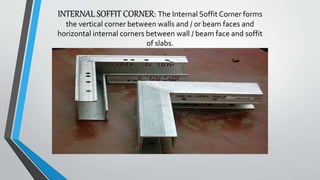

Mivan is an aluminum formwork system originally developed in Europe and manufactured in Malaysia since 1990. It is used globally for constructing large numbers of structures rapidly. The system uses lightweight, reusable aluminum panels to cast concrete walls and slabs together in a single pour. This creates a monolithic structure with smooth finishes, high strength, and speed of construction. The document discusses the history and components of the Mivan system, provides examples of its use, and outlines its advantages over conventional construction methods like reduced time, costs, and labor needs. It also notes some limitations and concludes the technology has great potential for affordable housing development in India.