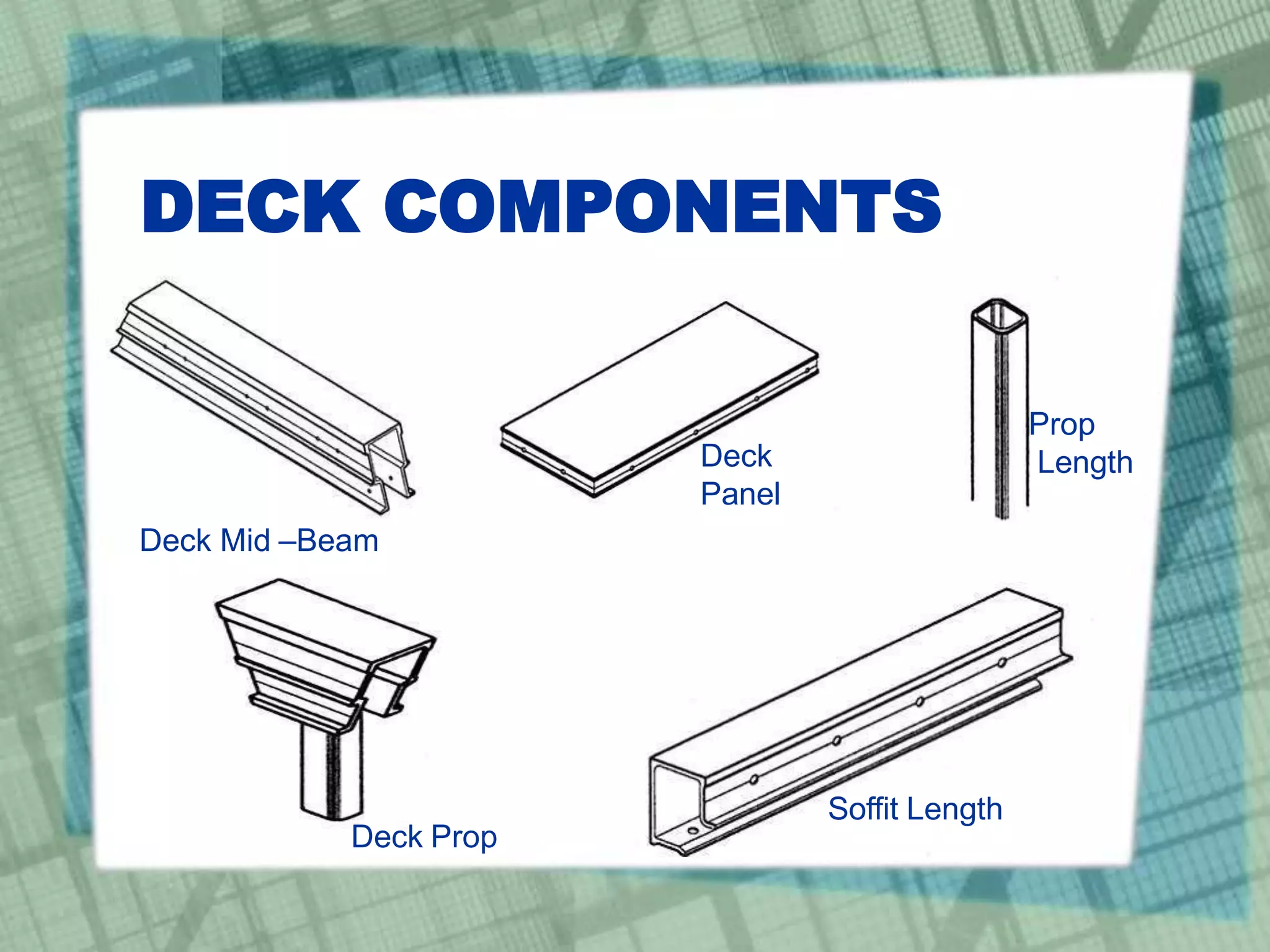

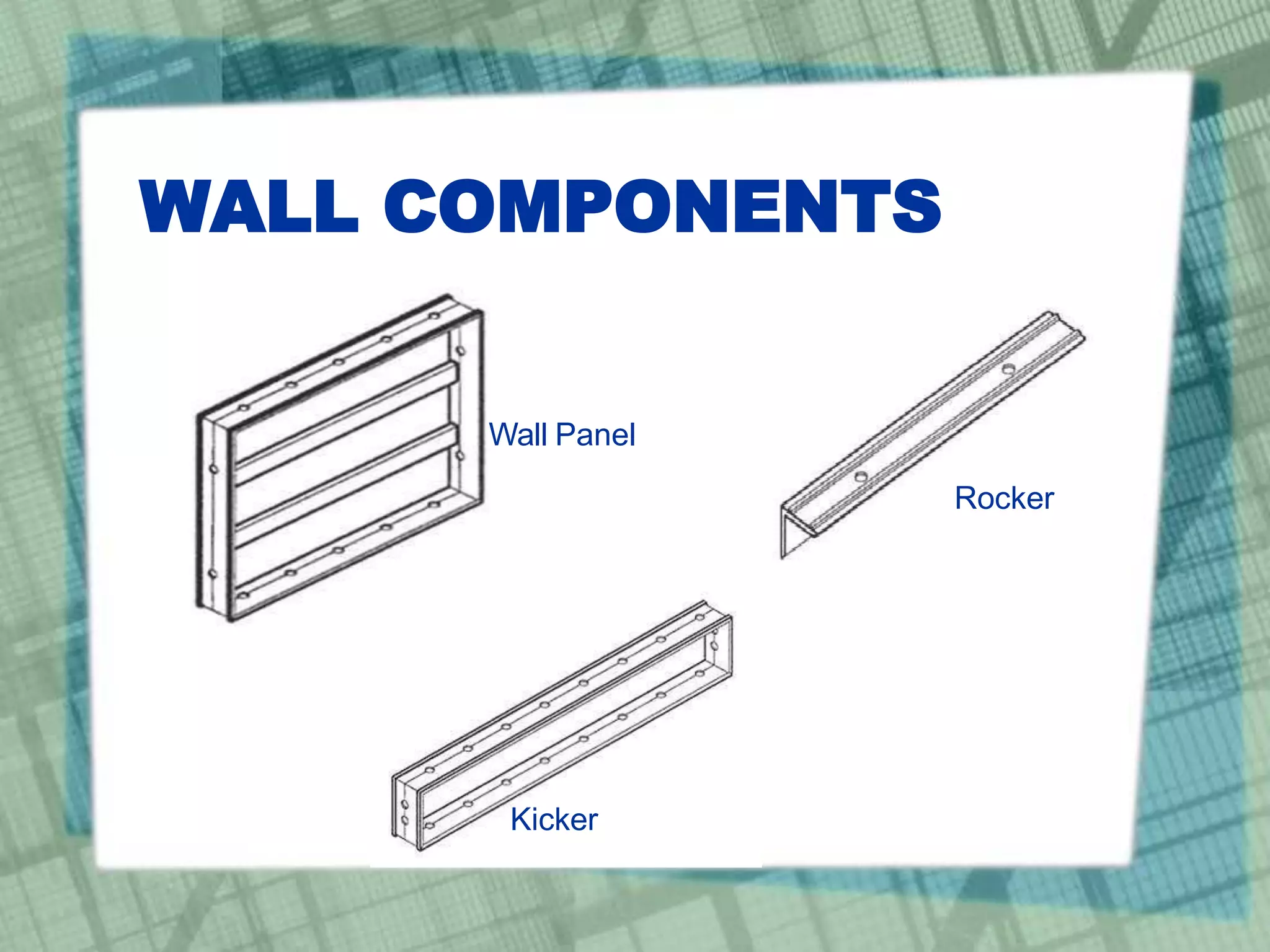

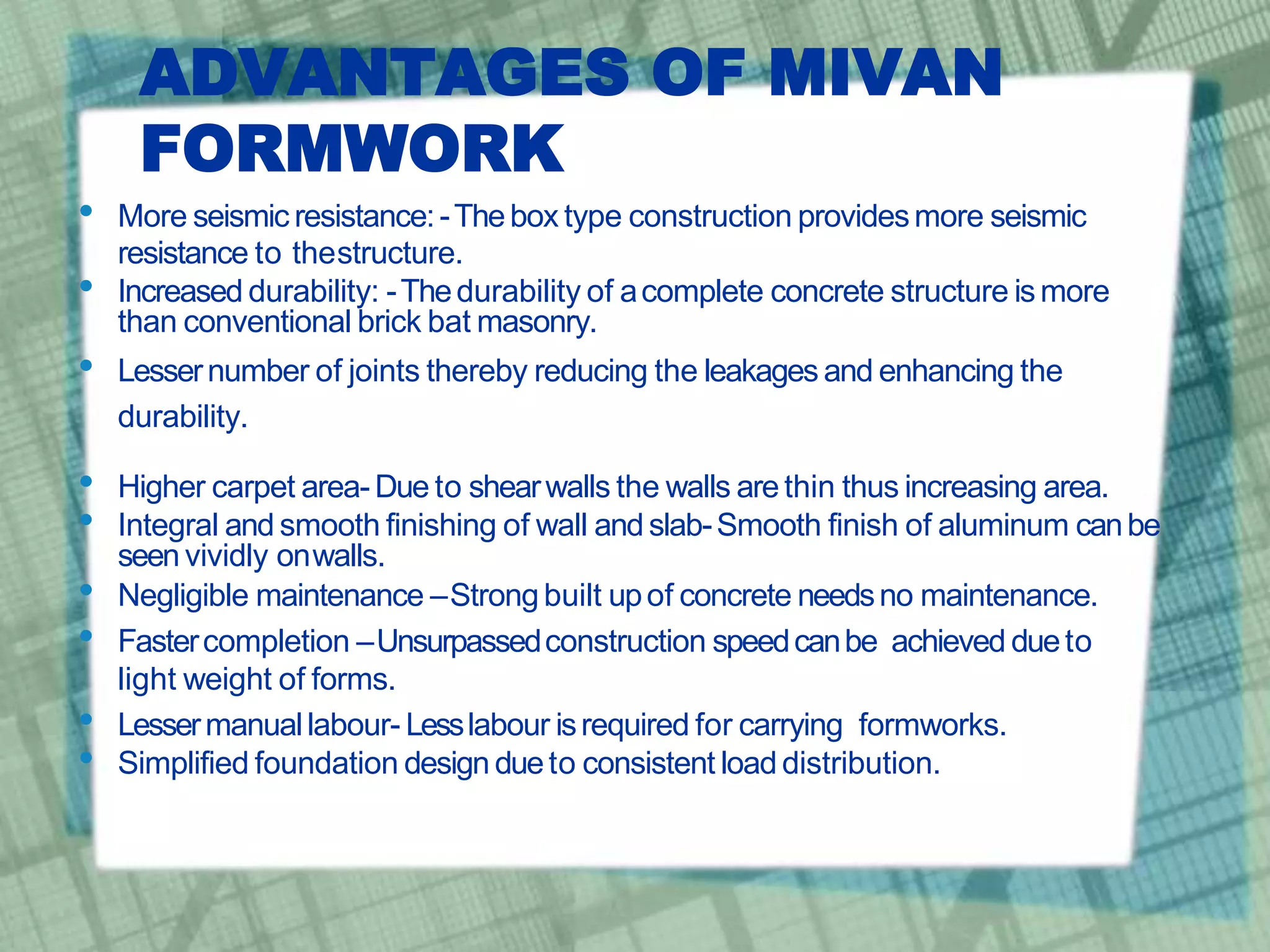

Mivan formwork is an aluminum alloy formwork system originally developed in Europe. It is now widely manufactured and used in Malaysia. The system uses lightweight aluminum forms to construct concrete walls and slabs in a continuous pour. This allows for fast, accurate construction of buildings at lower cost compared to conventional formwork. Some key advantages include high quality finishes with minimal plastering needed, less construction time per floor, minimal formwork waste, and good seismic resistance due to the box-type construction.