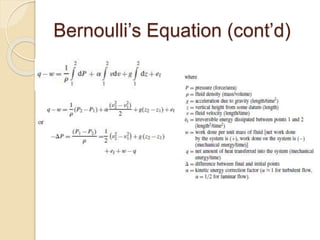

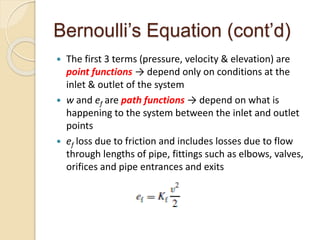

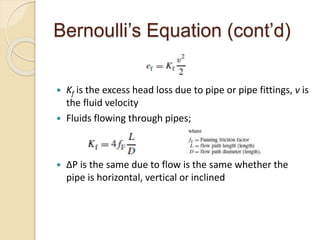

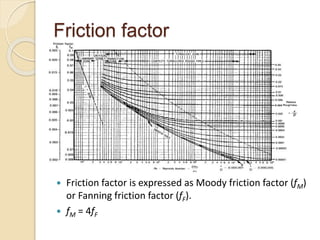

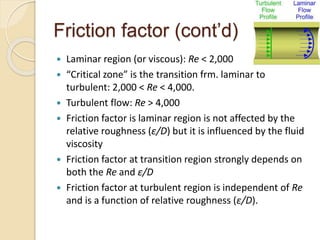

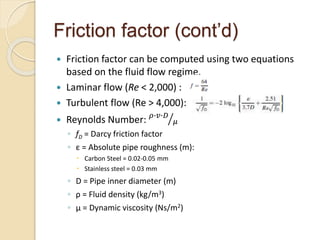

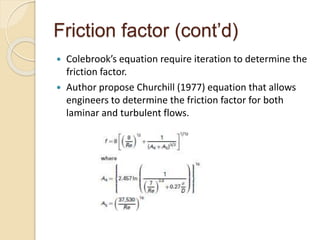

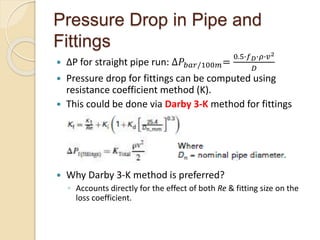

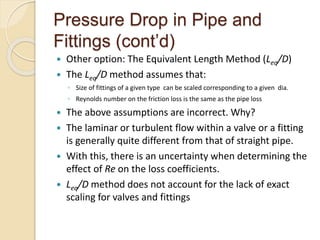

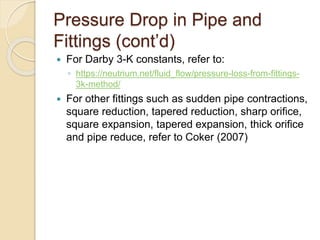

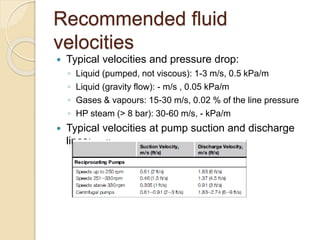

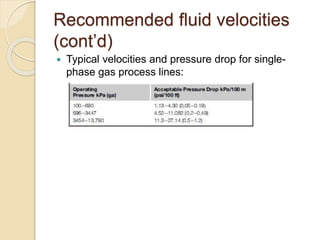

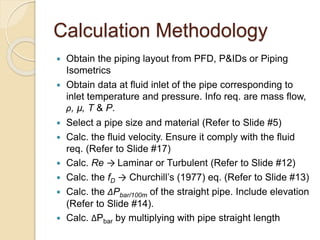

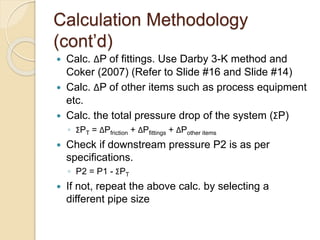

The document provides guidelines for pipe sizing in single-phase fluid flow, including definitions, calculations, and methodologies to determine pressure drop in pipes and fittings. It discusses Bernoulli’s equation, friction factors, and standard practices for calculating fluid velocity and pipe pressure drops using various methods. Additionally, references to essential literature are included for further reading on the topic.