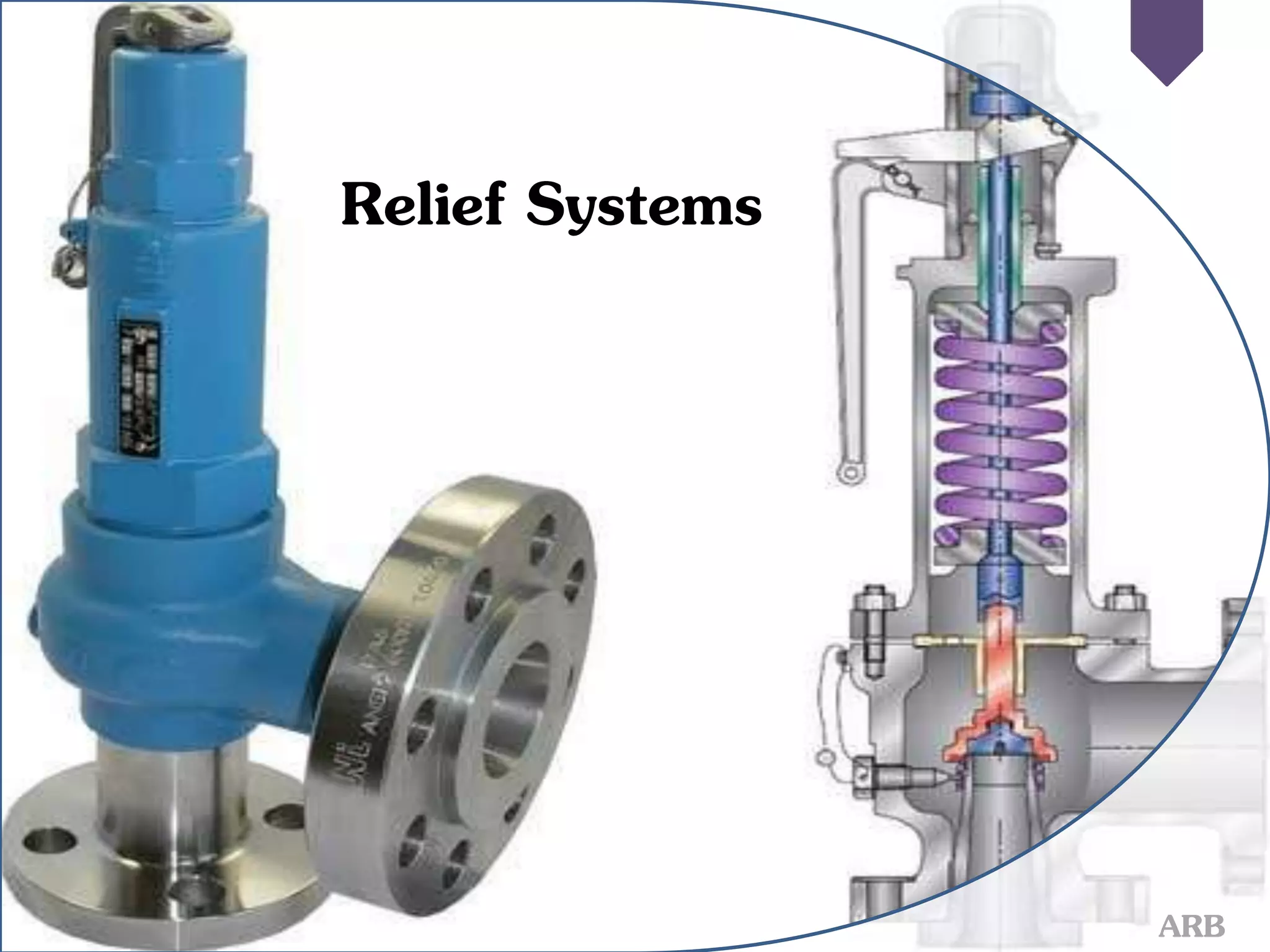

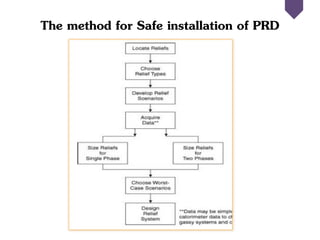

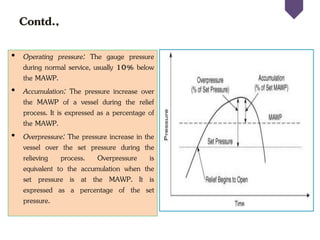

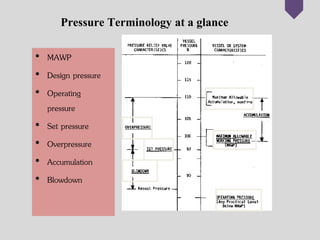

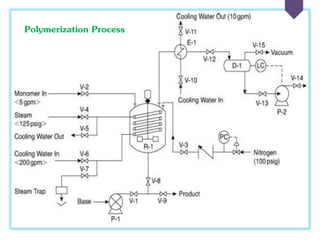

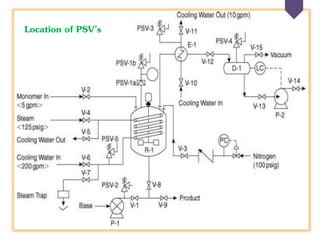

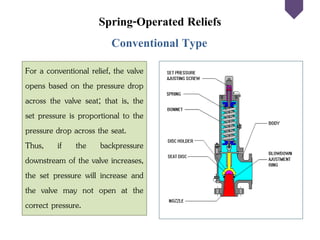

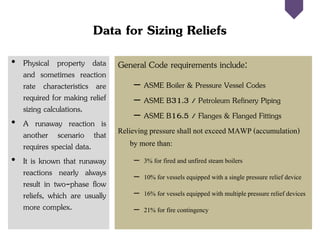

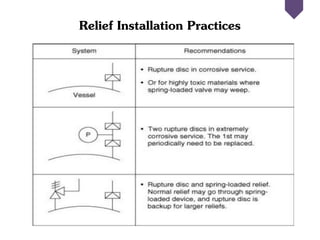

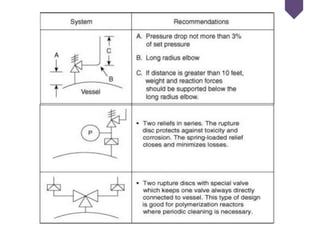

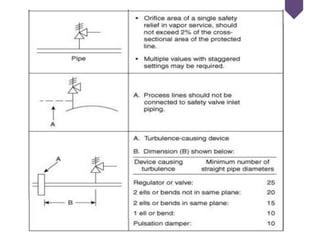

This document provides an overview of relief systems used in chemical plants. It defines key pressure relief terminology and describes the purpose and characteristics of different types of relief devices, including spring-operated reliefs, rupture discs, pilot-operated reliefs, and buckling pin reliefs. Guidelines are provided for specifying the appropriate location of reliefs on process equipment. Data requirements and code standards for properly sizing relief systems are also discussed.