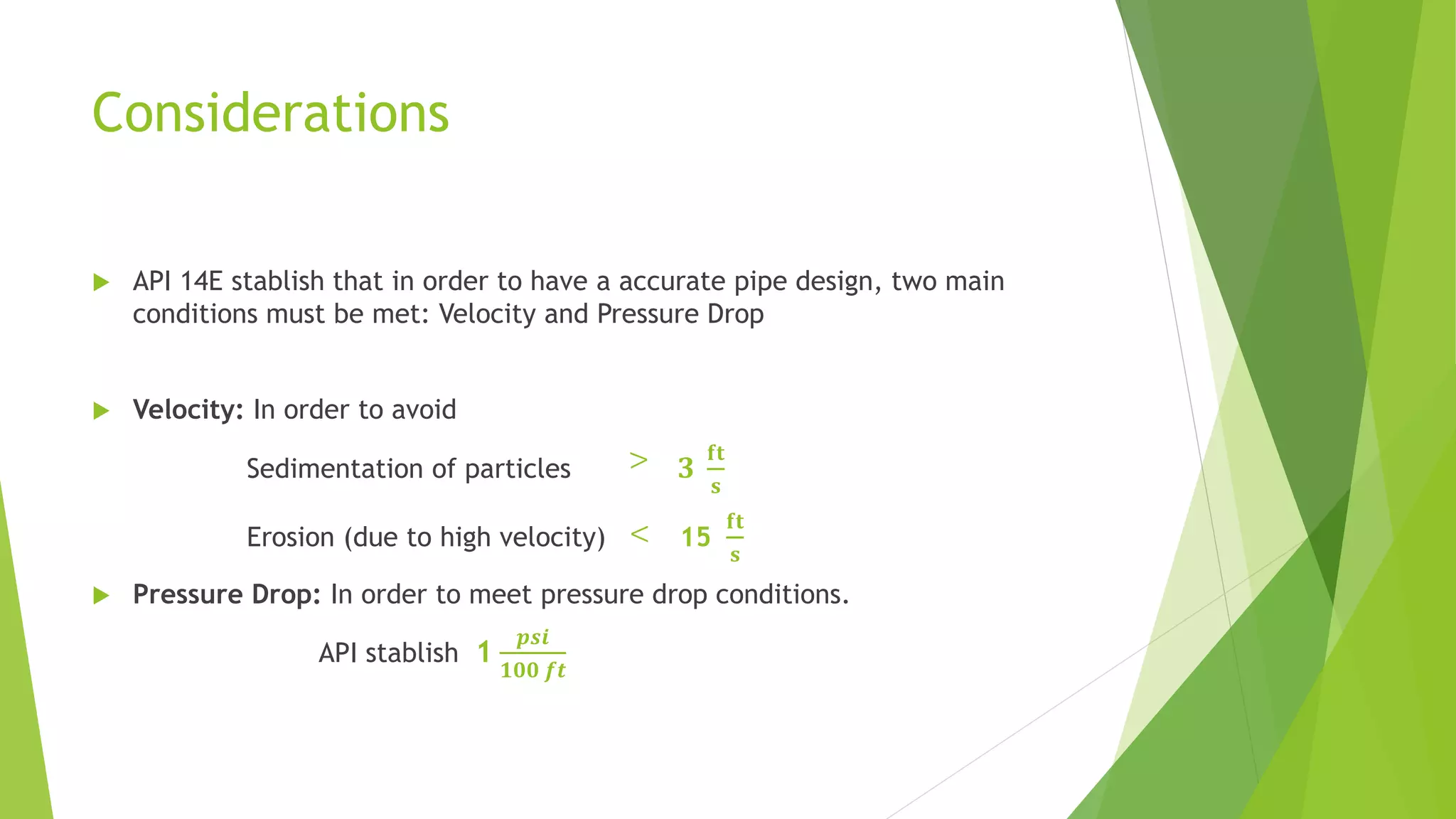

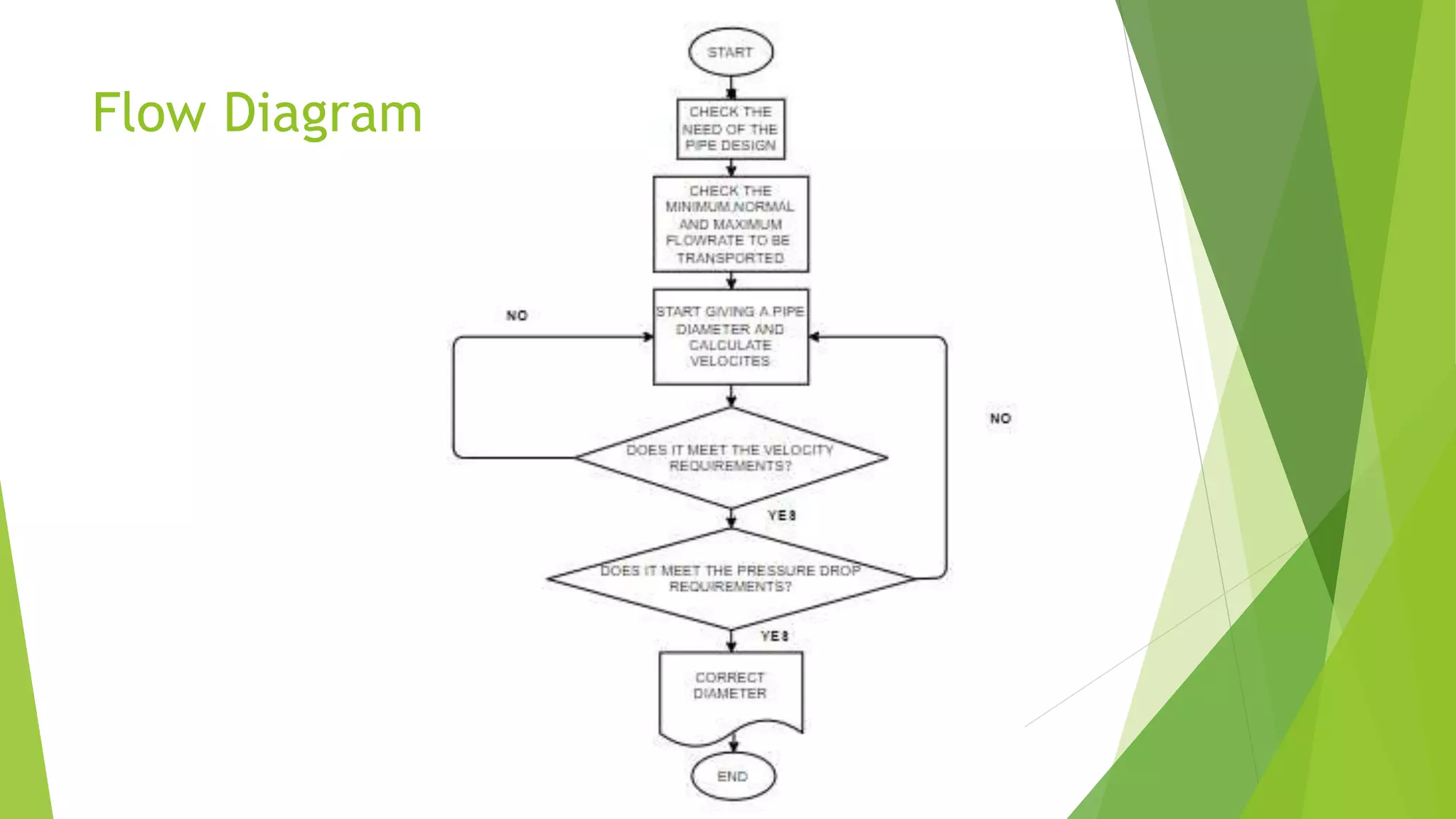

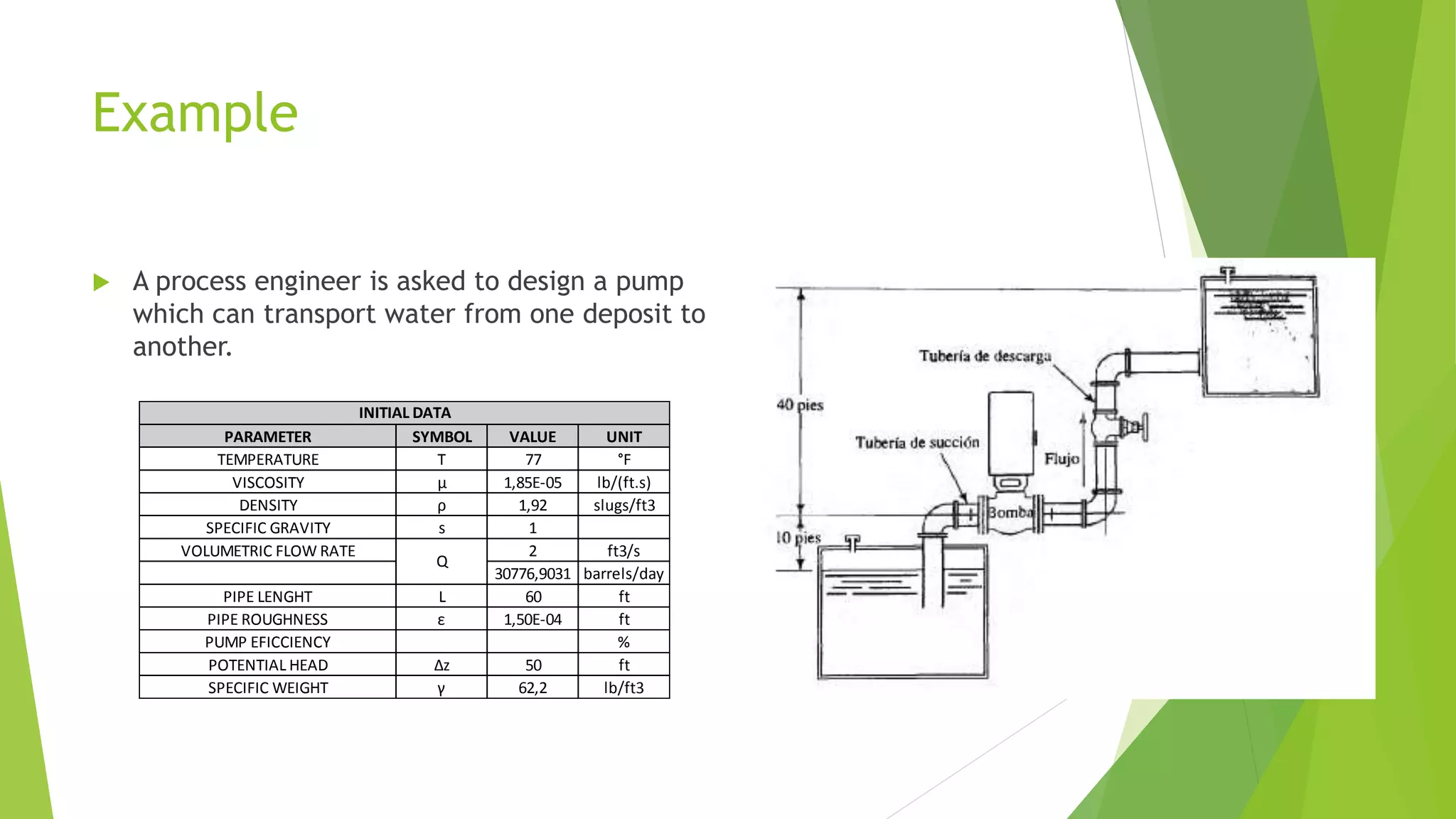

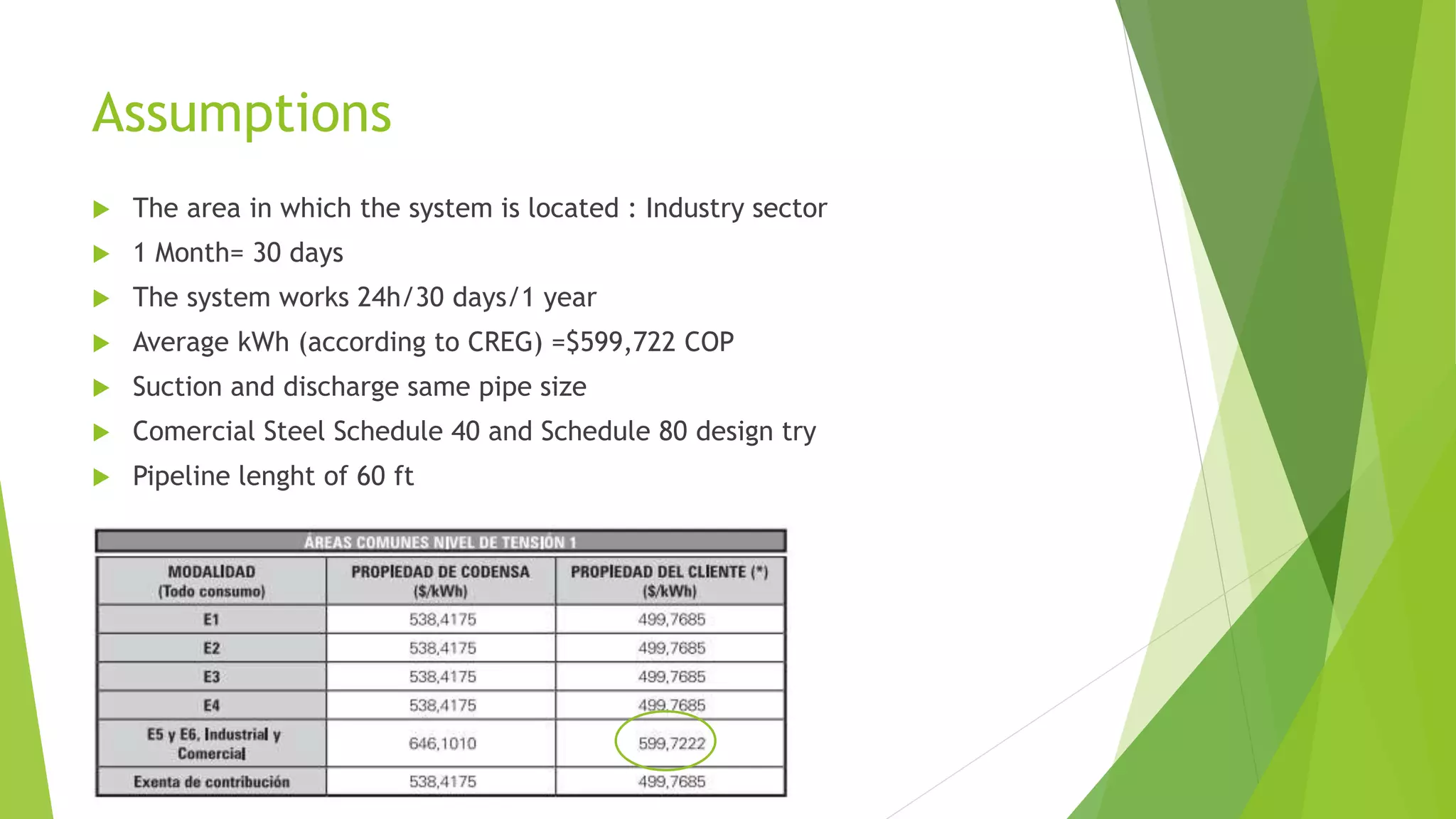

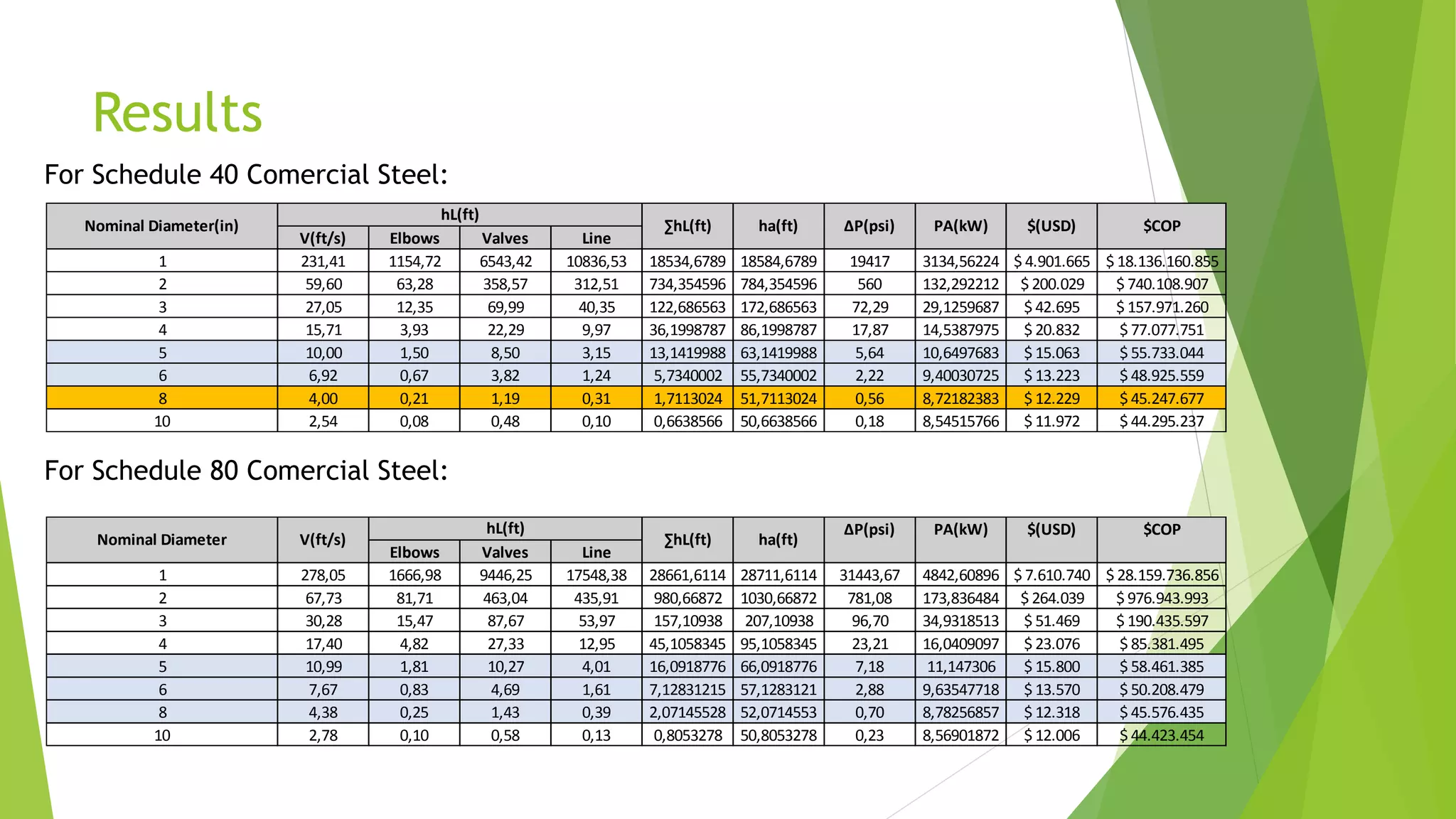

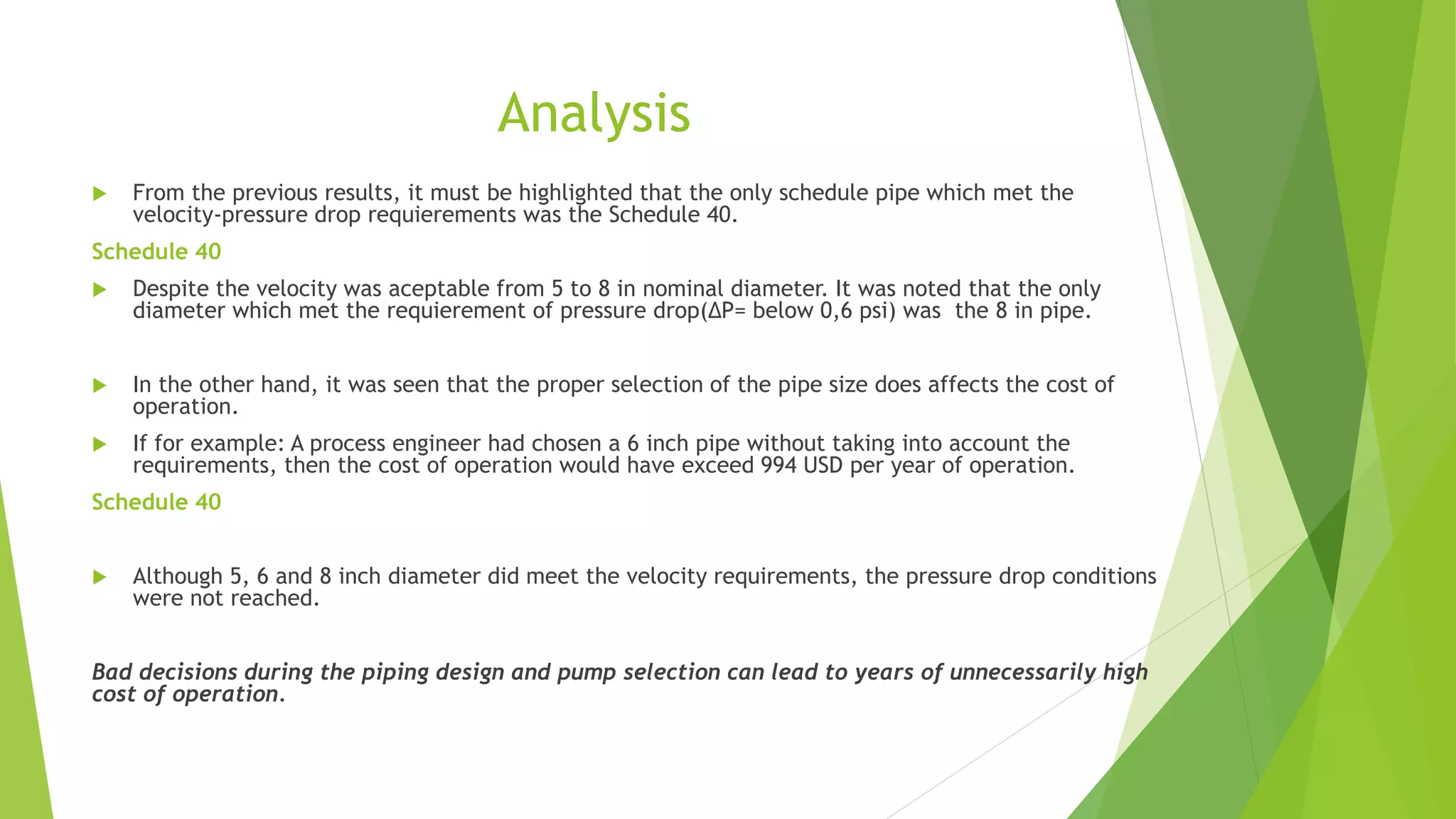

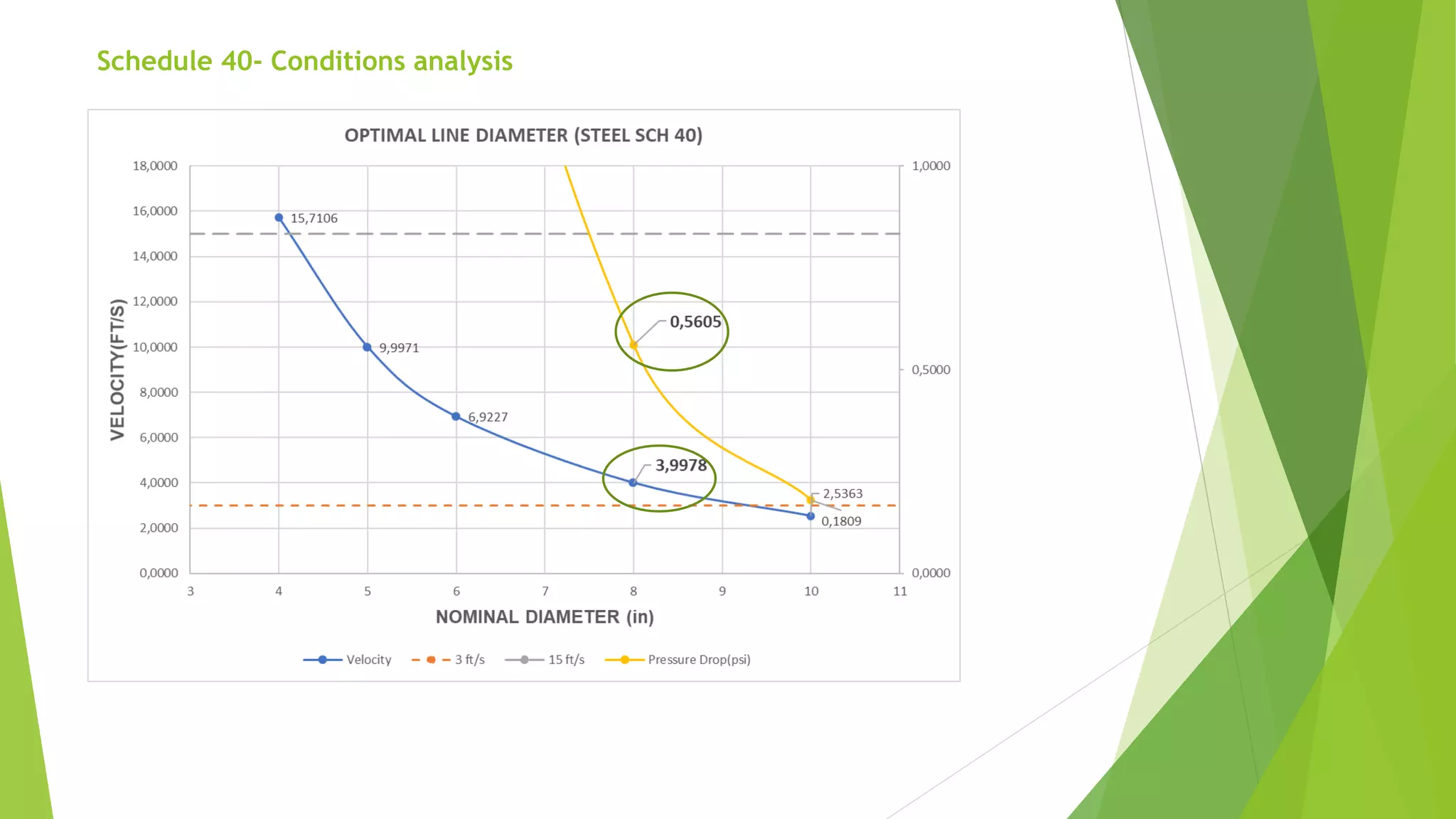

This document summarizes the key steps in designing liquid pipelines according to API 14E standards. It discusses important considerations like ensuring velocity is below 15 feet per second to avoid erosion and pressure drop is below 1 psi per 100 feet. The document then provides an example calculation for sizing a water pipeline using schedule 40 and 80 steel pipes. It determines that an 8-inch schedule 40 pipe meets both velocity and pressure drop requirements and has the lowest annual operating costs.

![REFERENCES

[1] R. Mott, Mecánica de fluidos, Dayton: Pearson, 2006.

[2] A. 14E, Recommended Practice for Design and Installation of Offshore Production Platform

Piping Systems., Washington: American Pretroleum Institute, 1991.

[3] C. d. R. d. E. y. G. (CREG), «TARIFAS DE ENERGÍA ELÉCTRICA ($/kWh) REGULADAS POR LA

COMISIÓN DE REGULACIÓN DE ENERGÍAY GAS (CREG) JUNIO DE 2020,» ENEL CODENSA, 2020.

[4] B. d. l. R. d. Colombia, «Tasa Representativa de Mercado (TRM-Peso por dolar),» Banco de la

Republica de Colombia, Colombia, 2020.](https://image.slidesharecdn.com/linesizing-200826172649/75/Line-sizing-12-2048.jpg)