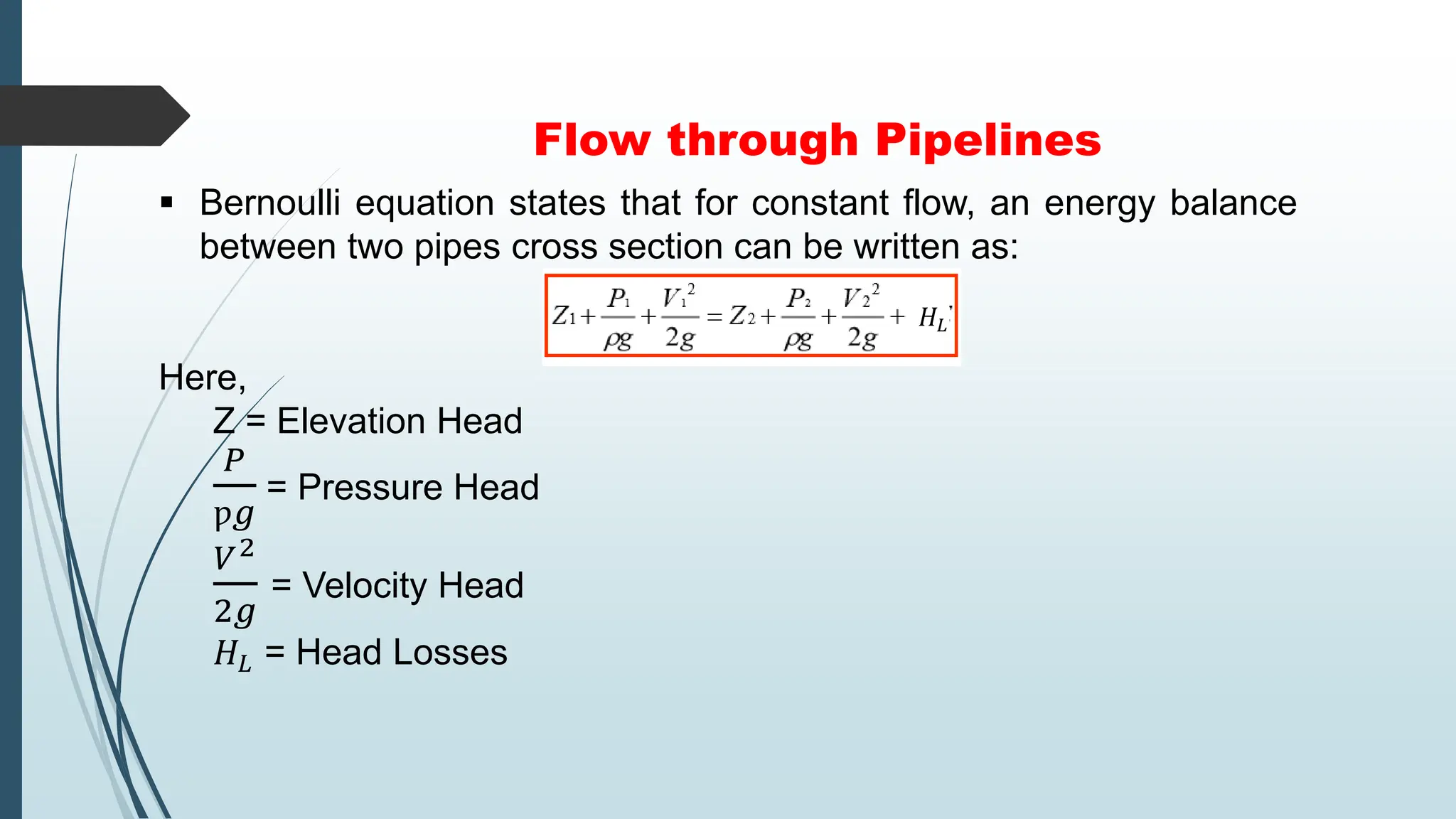

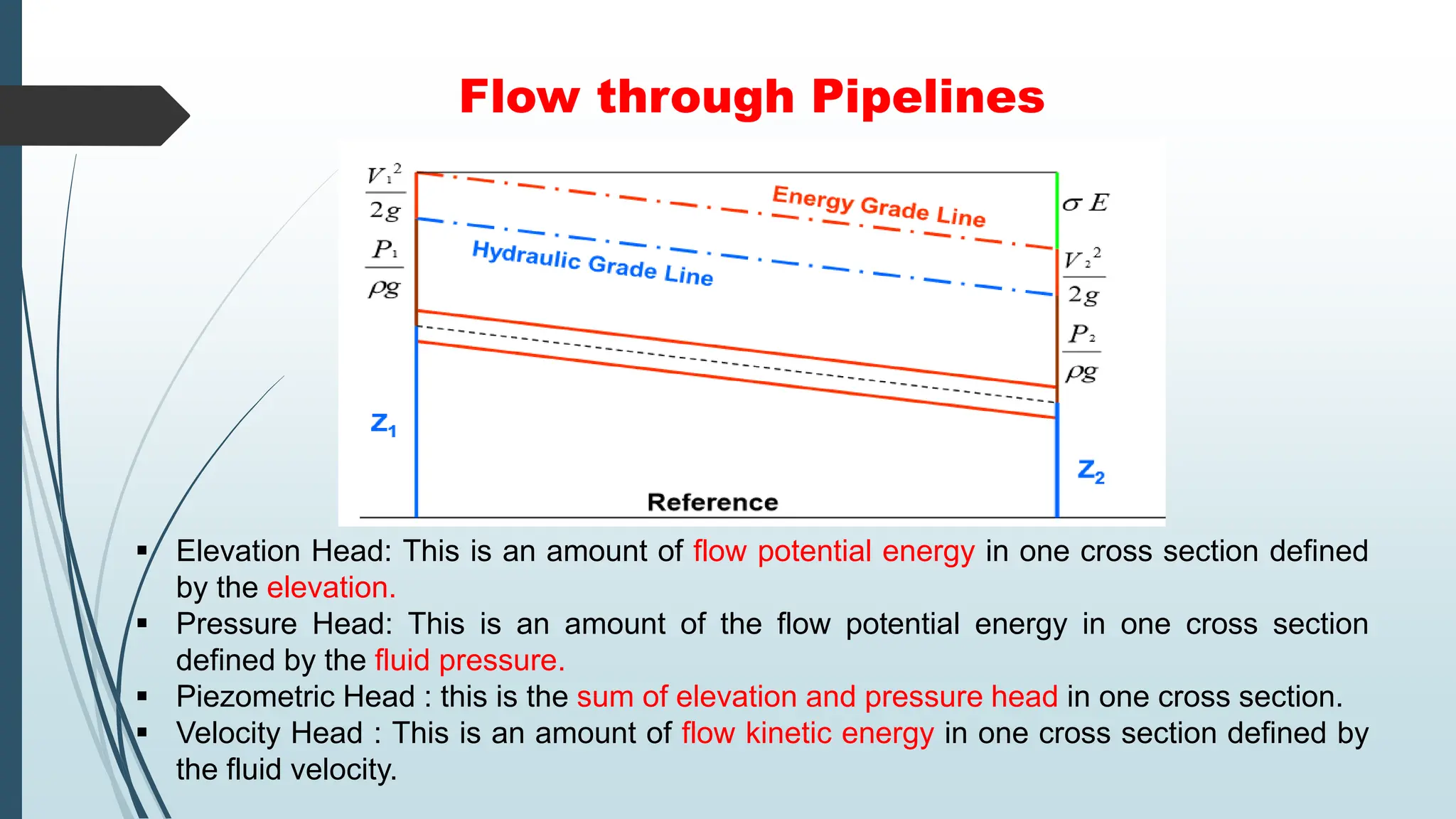

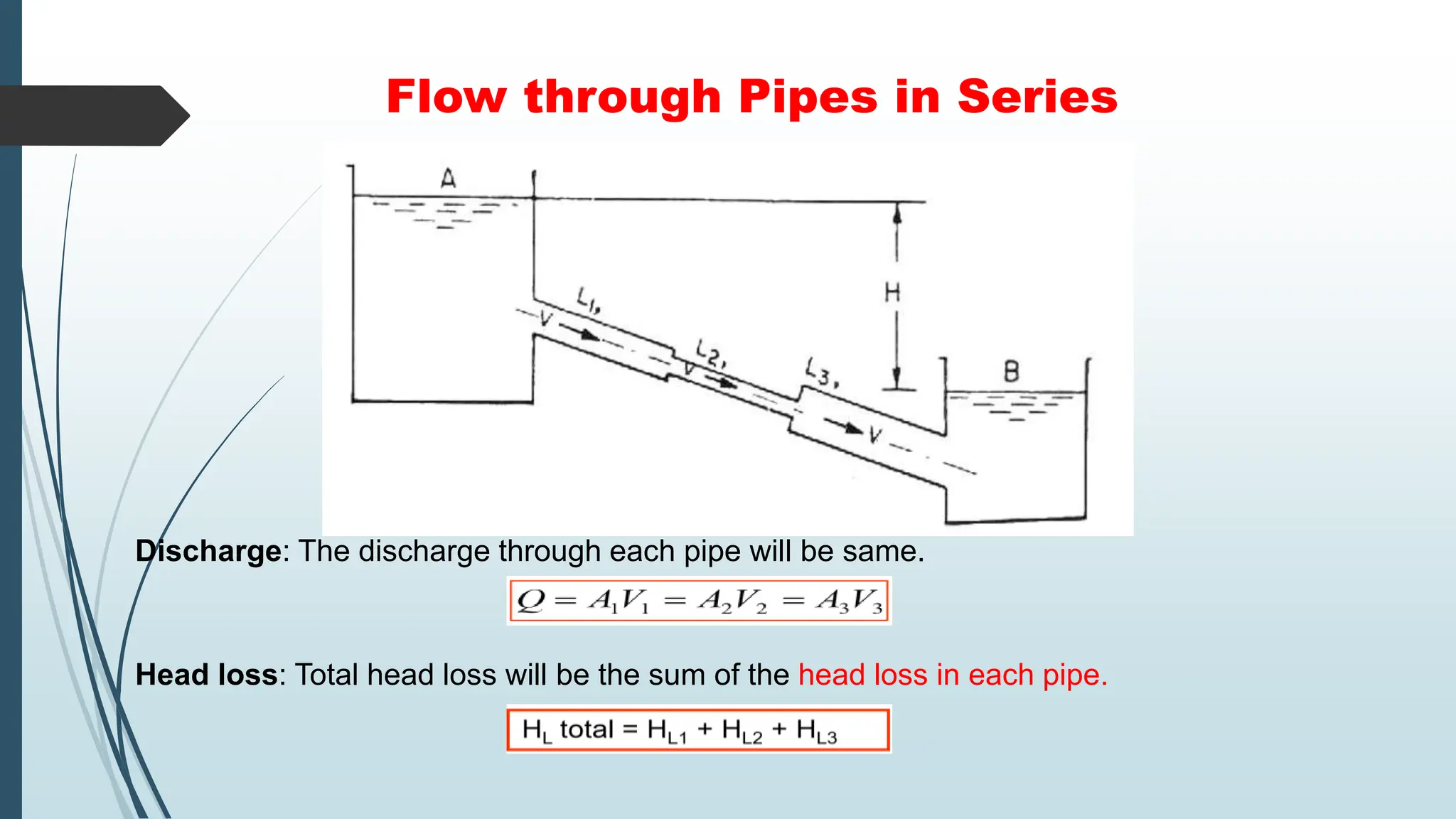

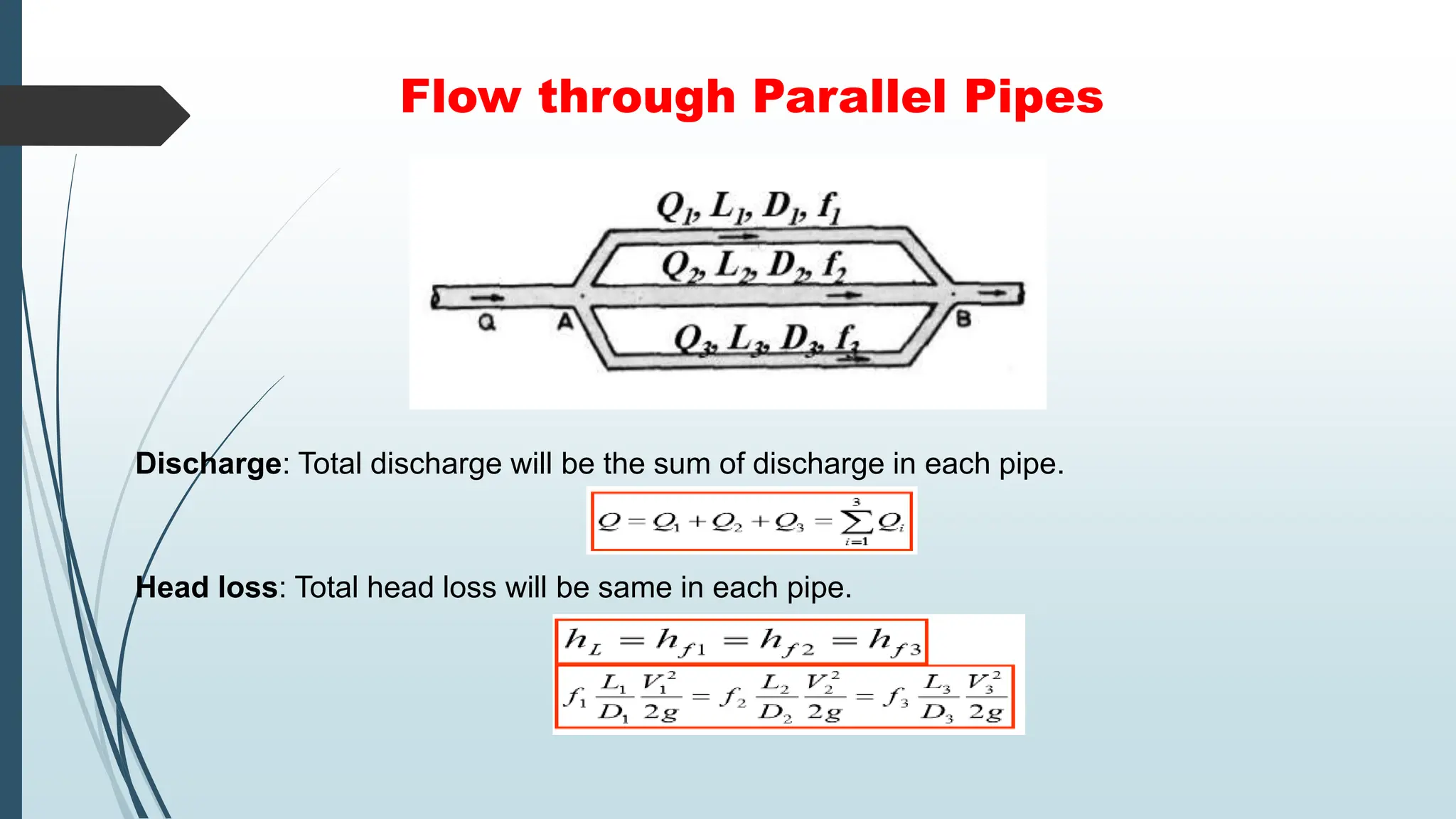

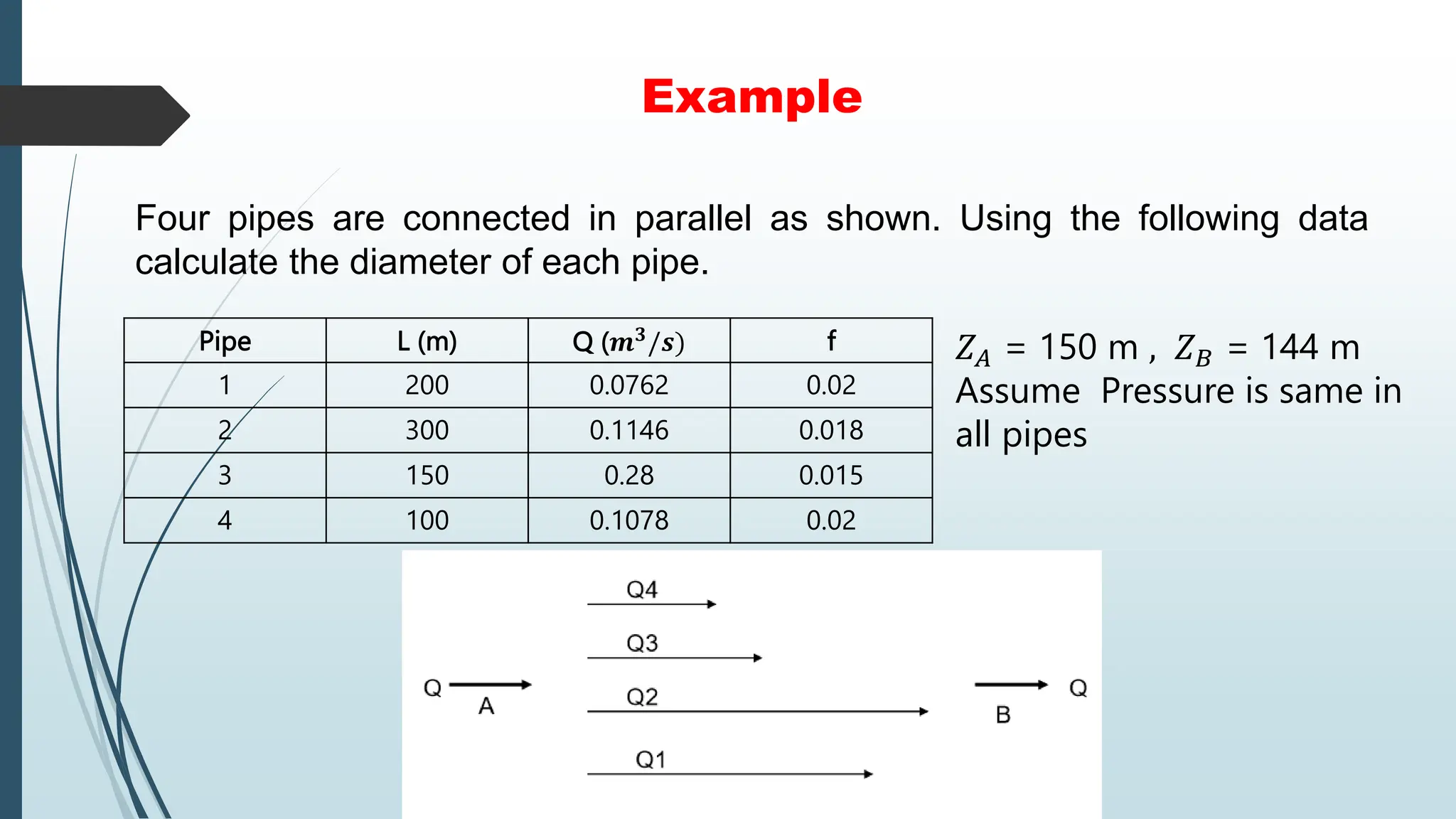

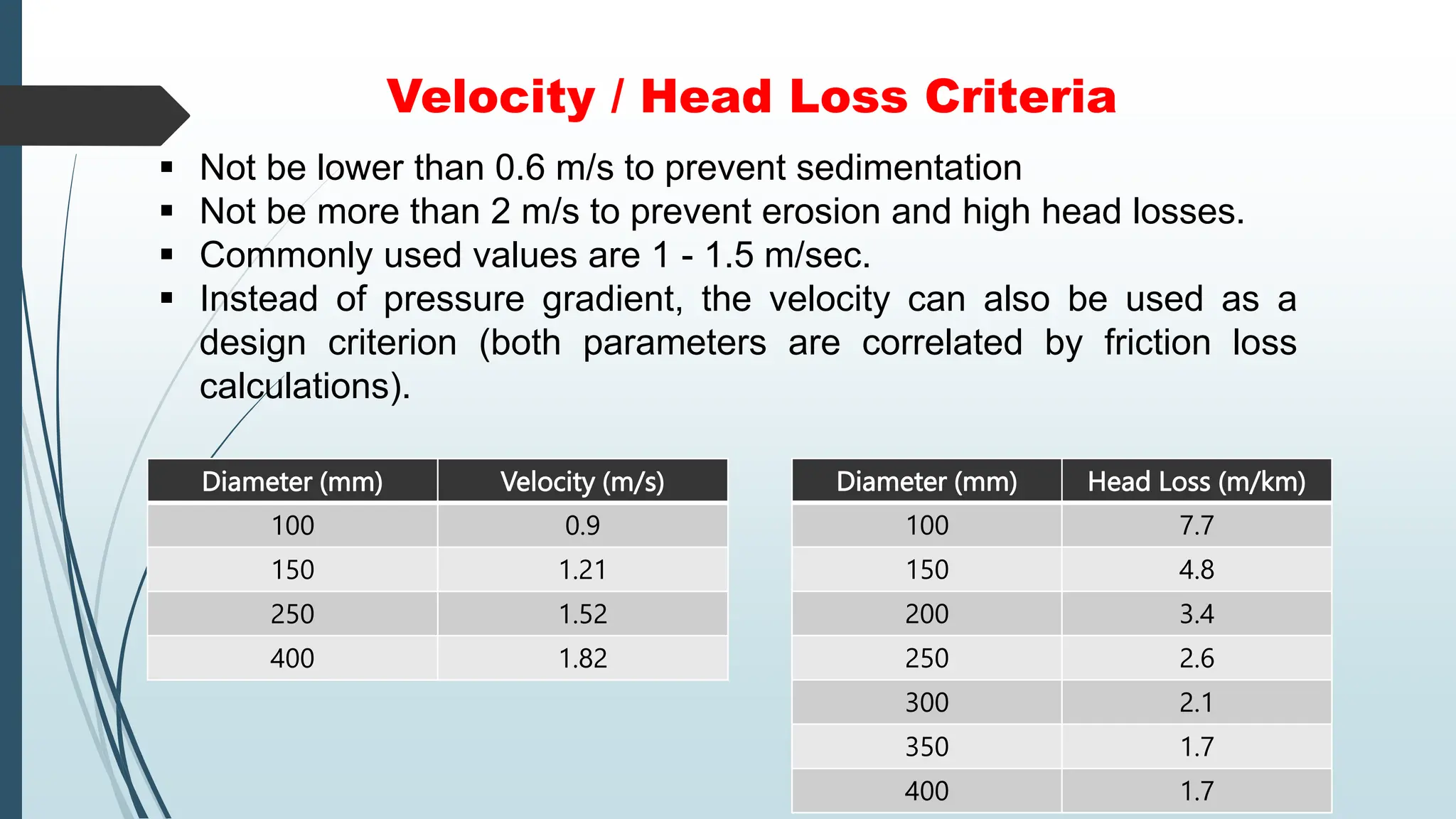

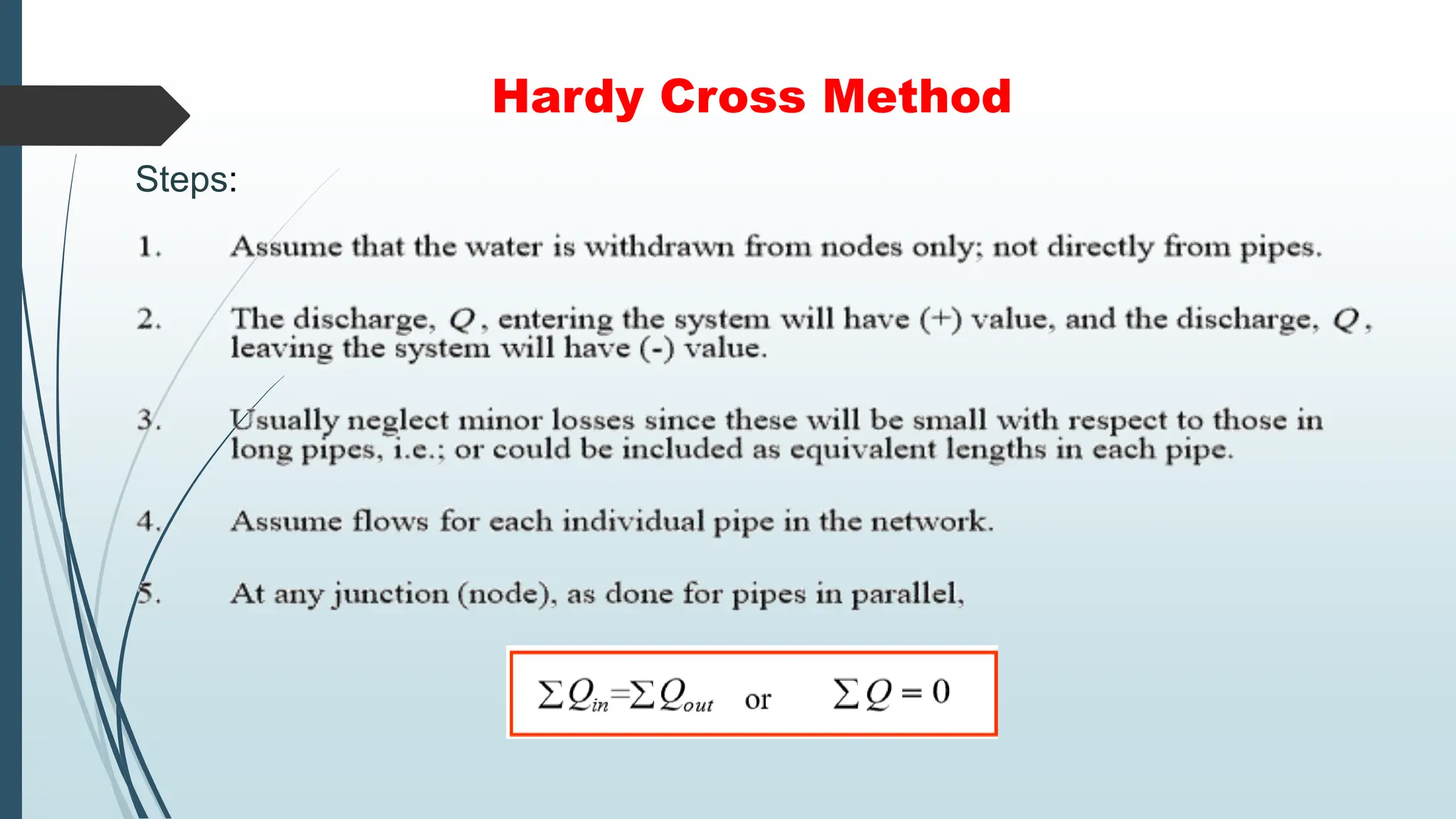

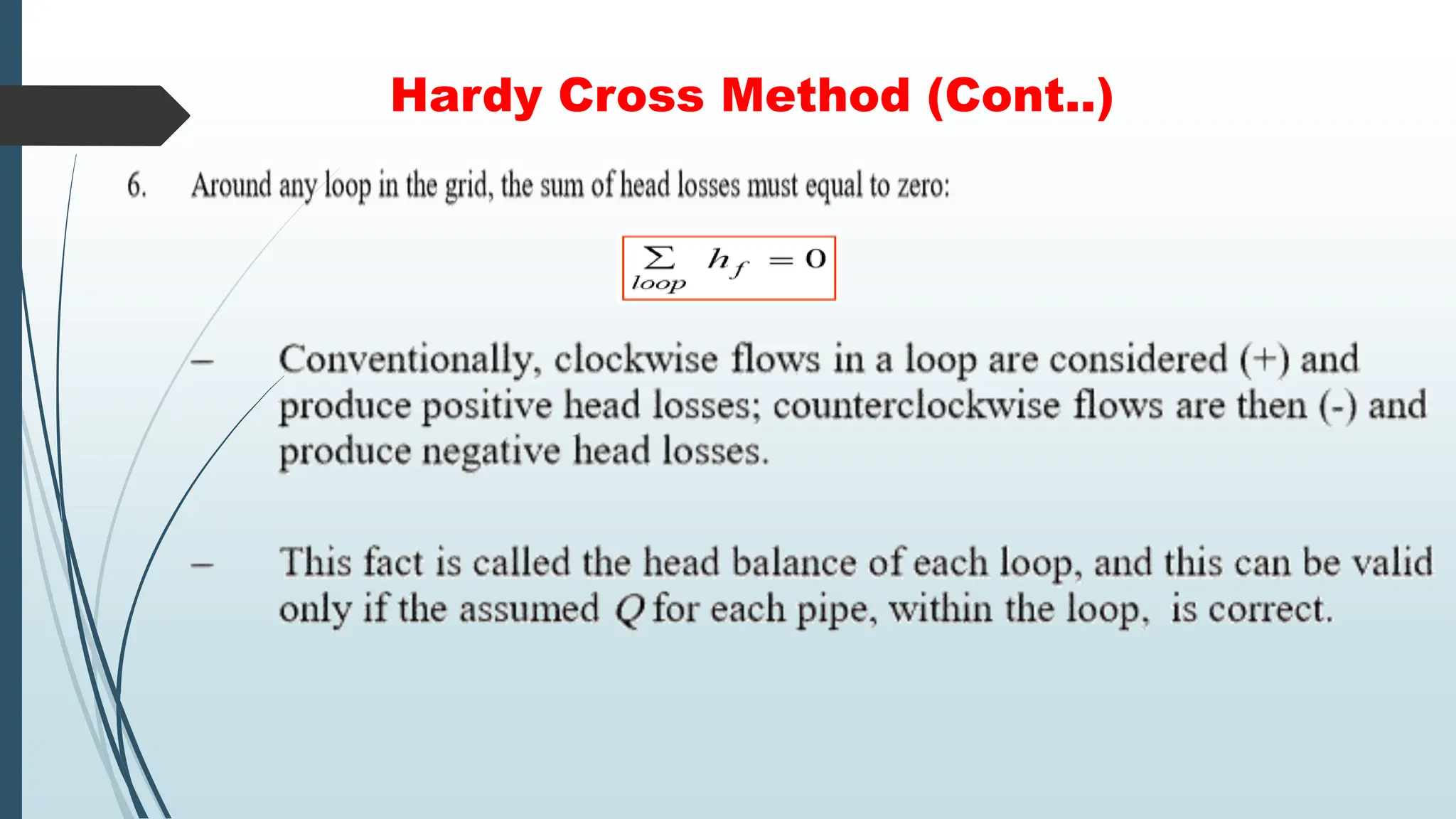

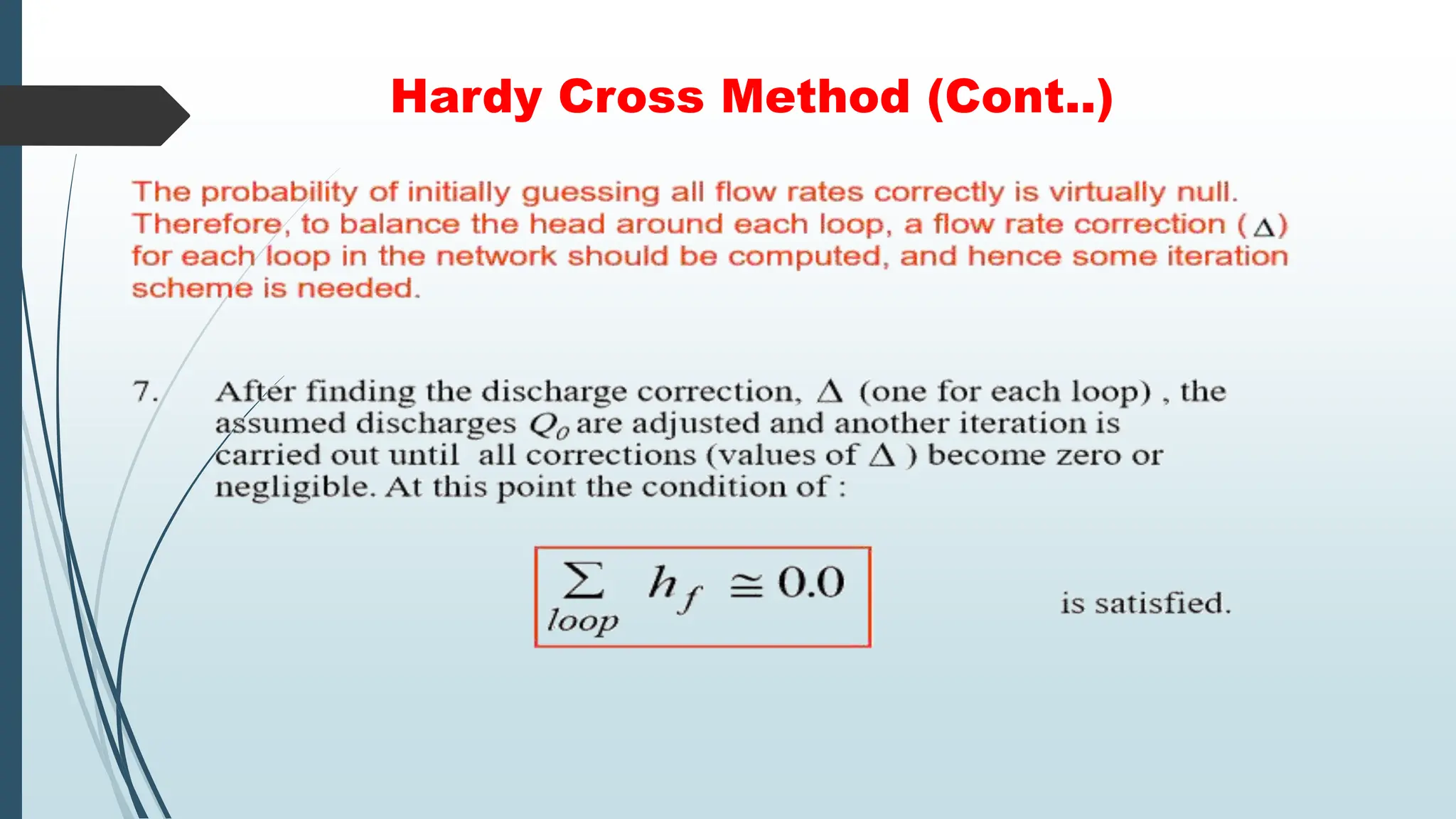

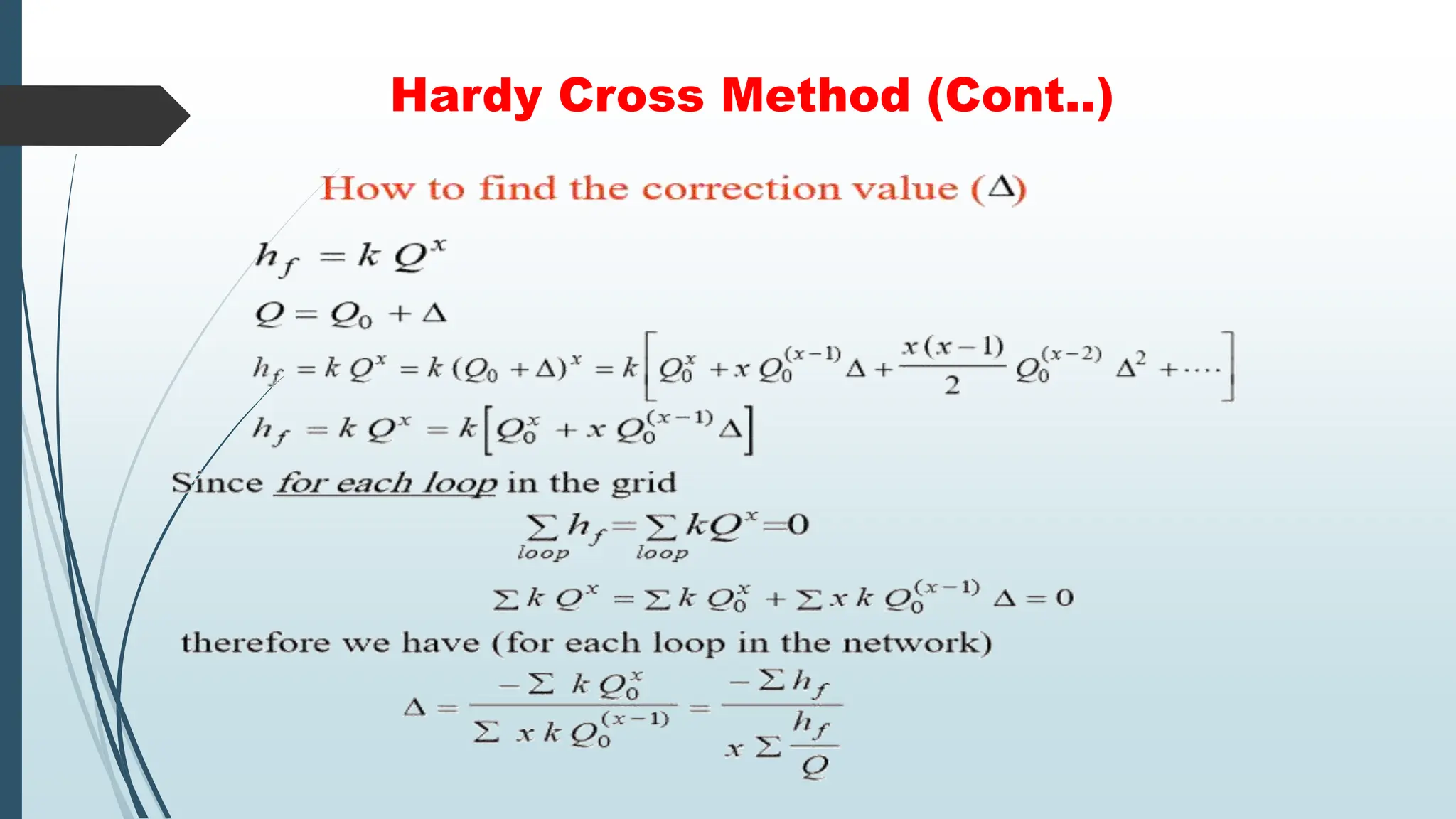

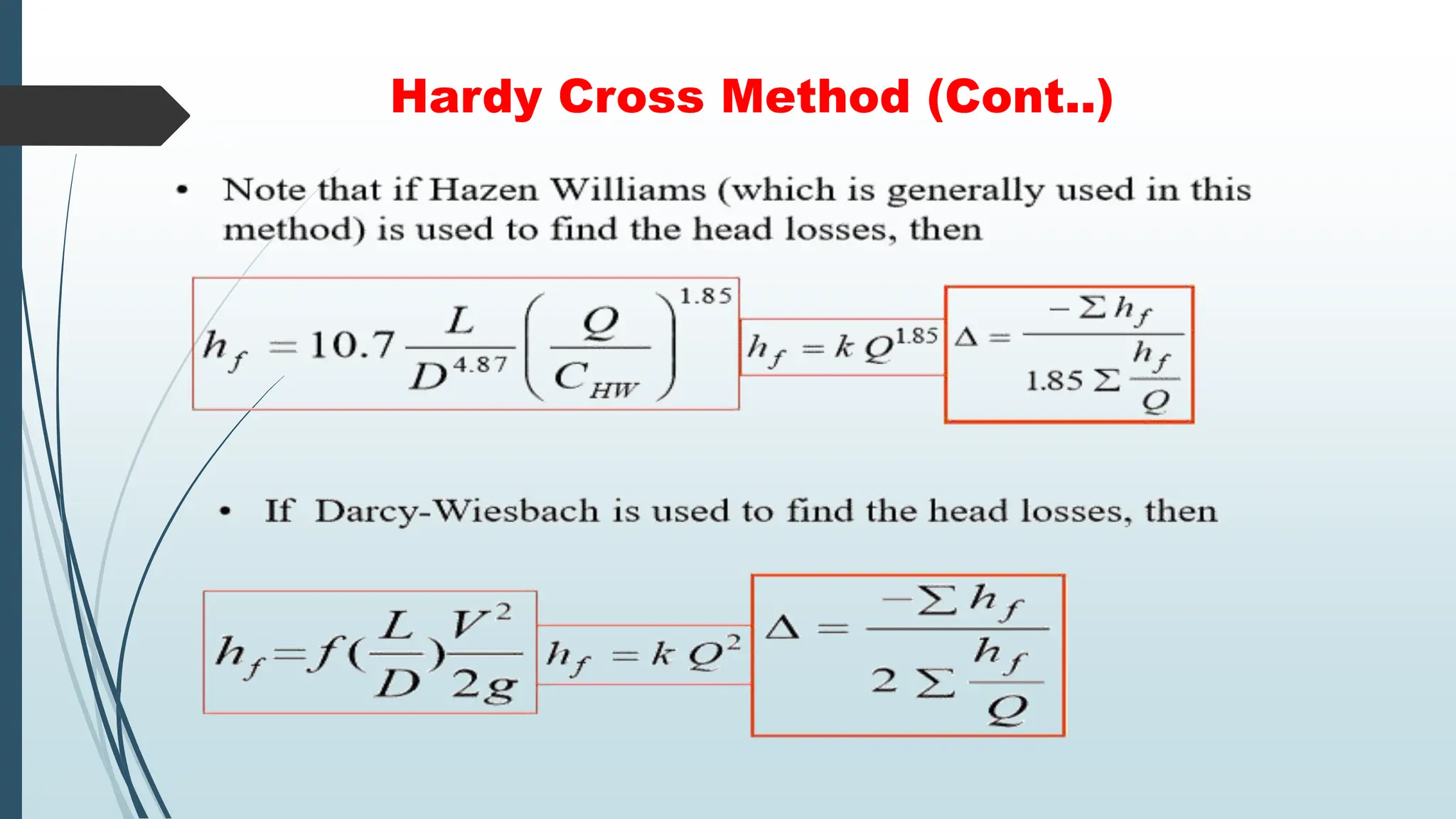

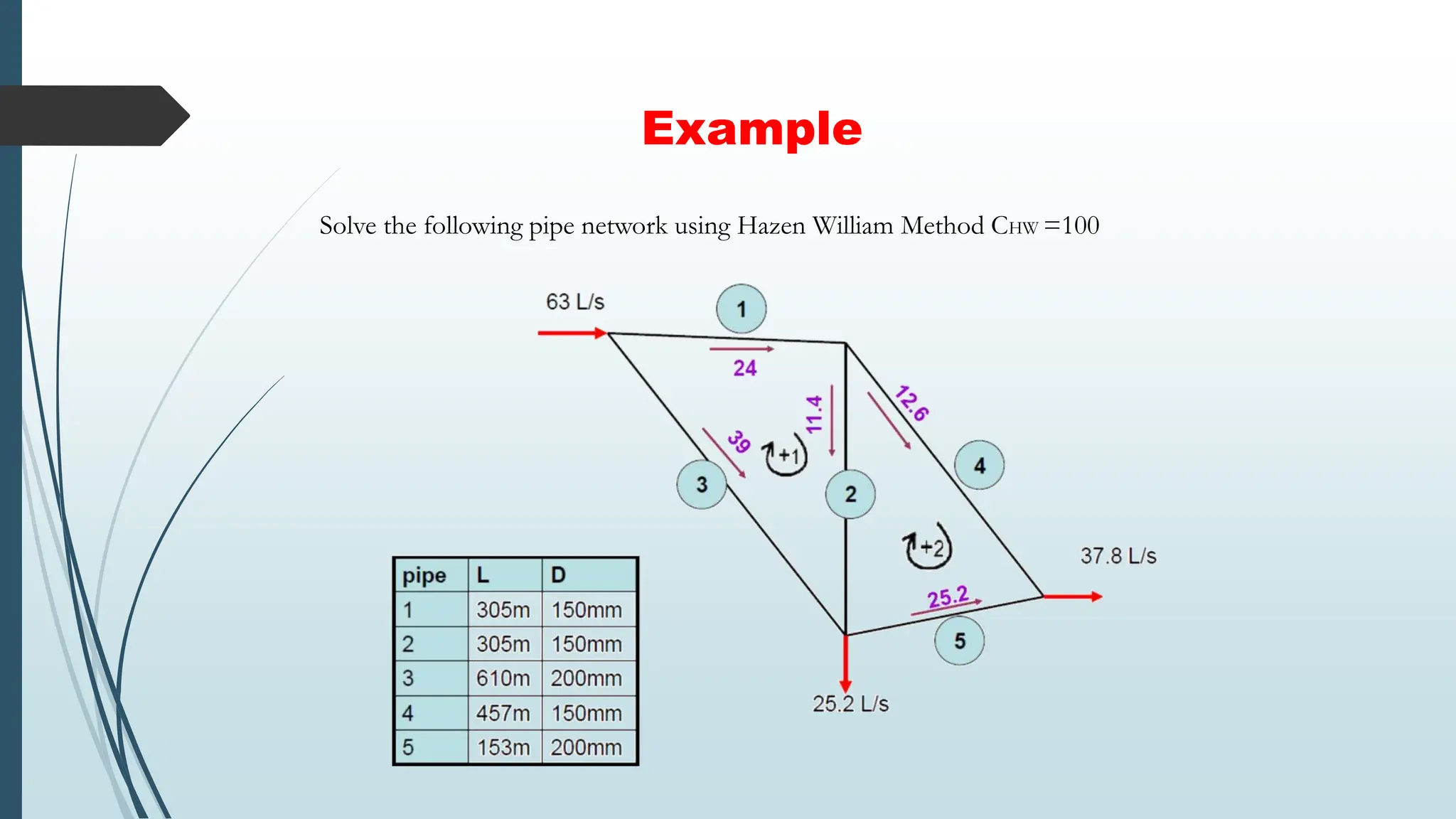

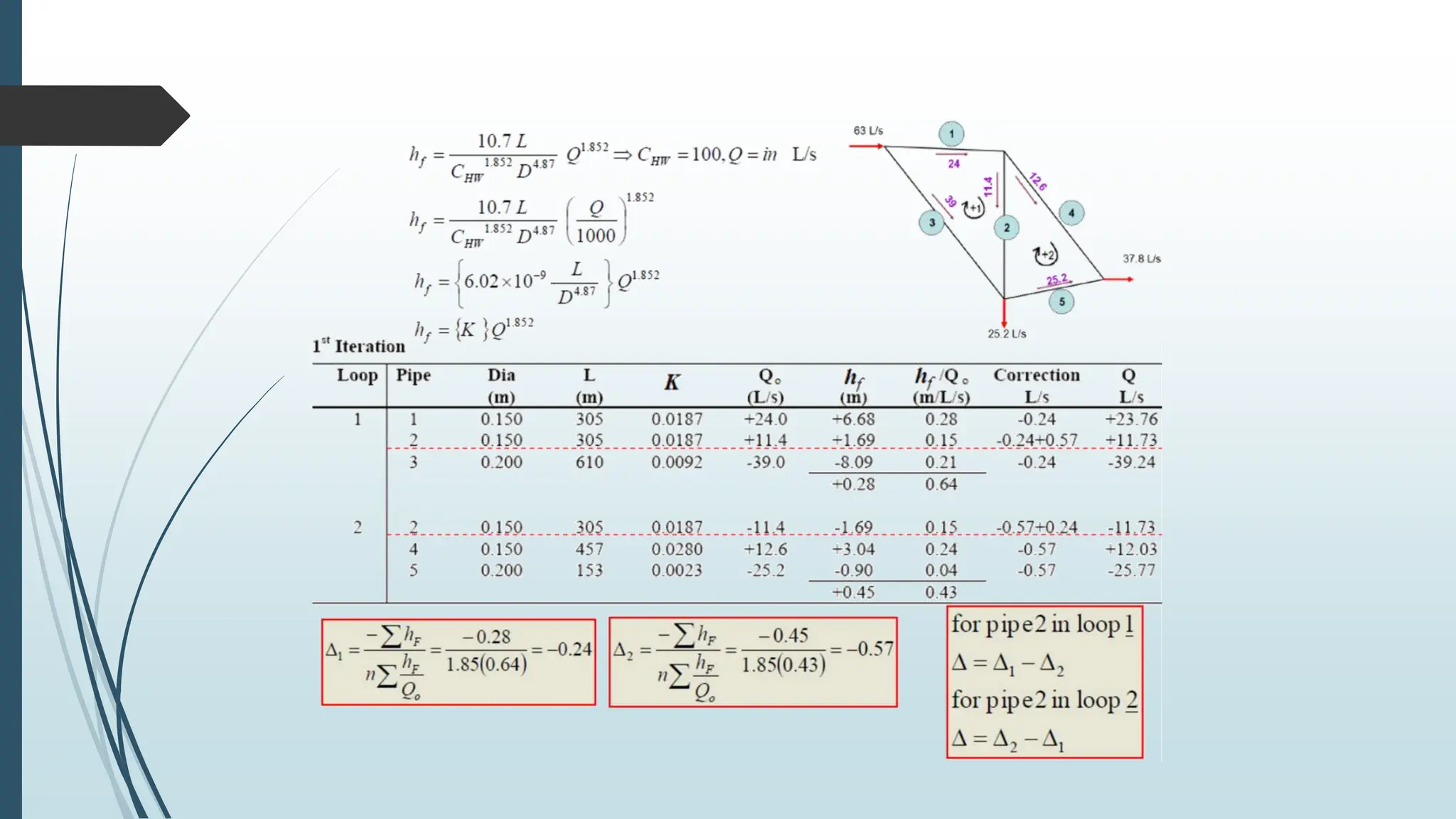

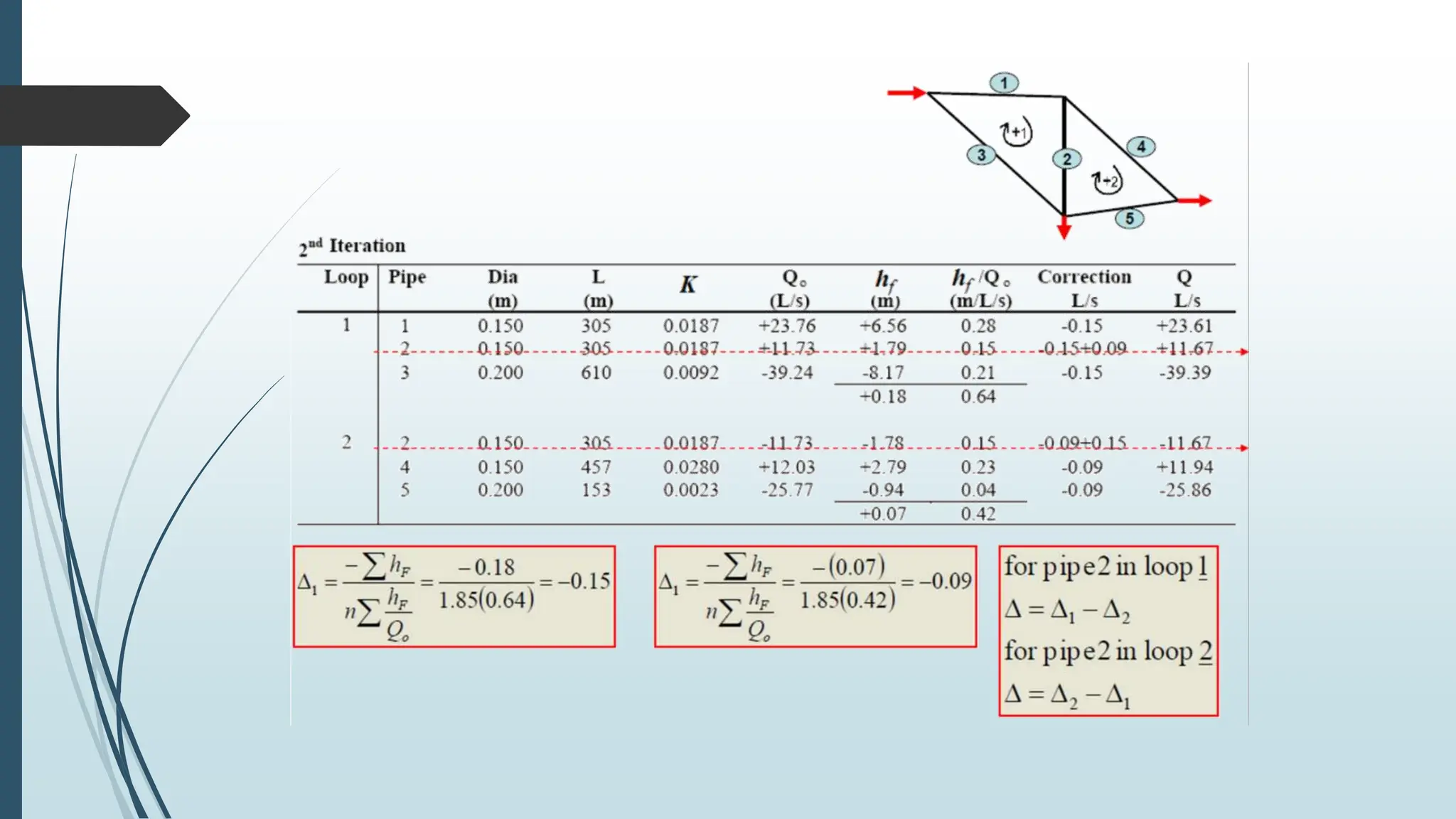

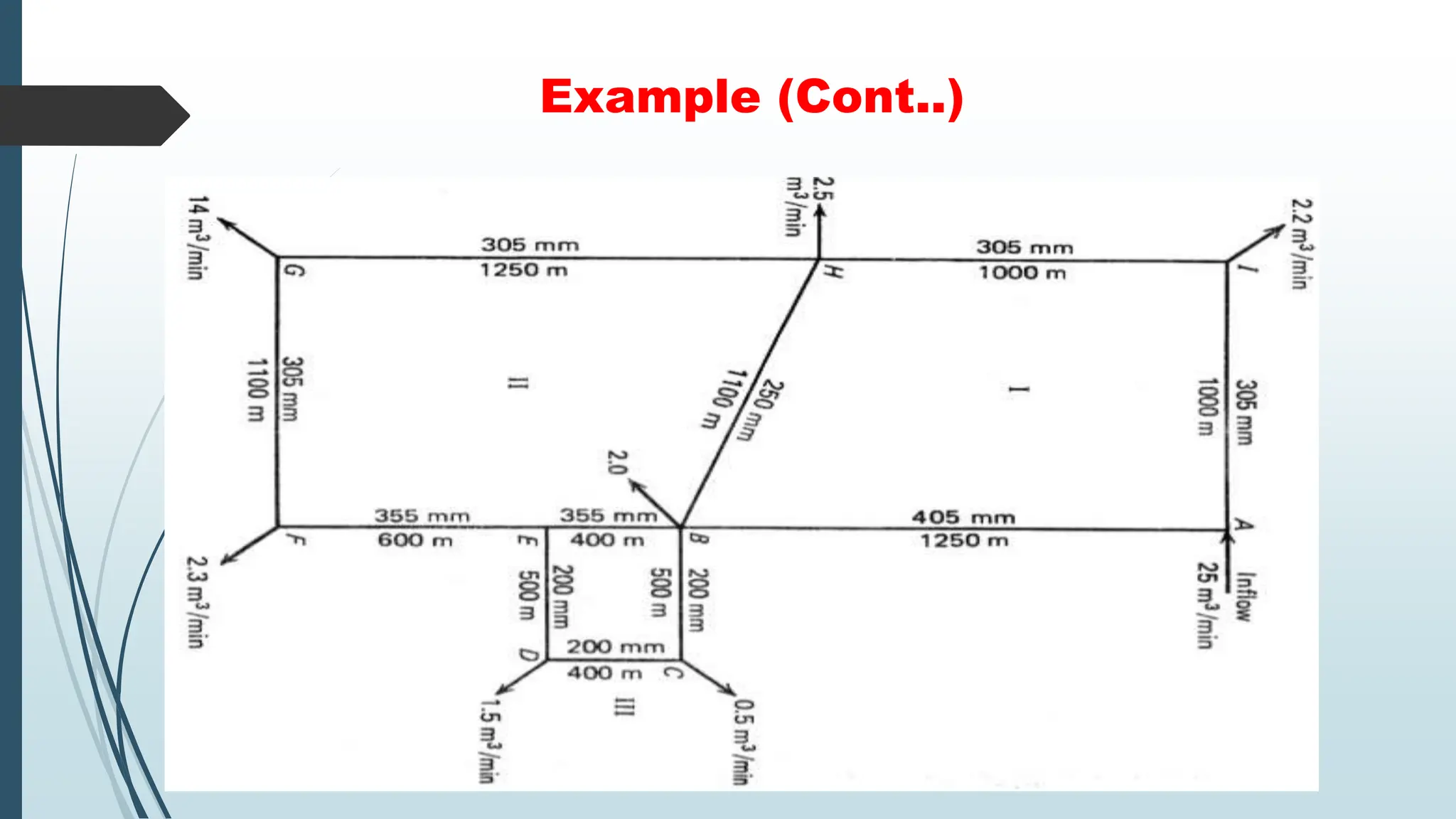

The document outlines hydraulic design principles for pipelines, covering aspects such as flow through pipes in series and parallel, velocity and head loss criteria, and pipeline network analysis methods like the Hardy Cross method. It emphasizes the importance of hydraulic design criteria including flow and pressure, proper material selection, and installation guidelines for effective fluid transport. Key materials used for pipework systems are categorized into metallic and non-metallic, with specific mentions of their applications and considerations for durability and corrosion resistance.