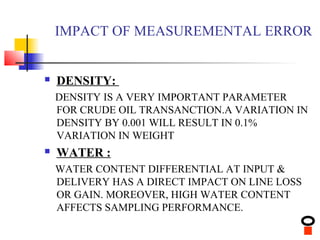

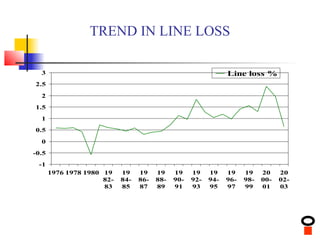

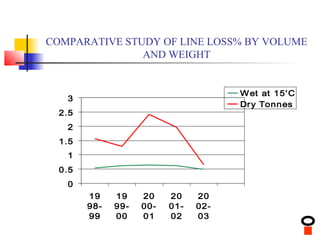

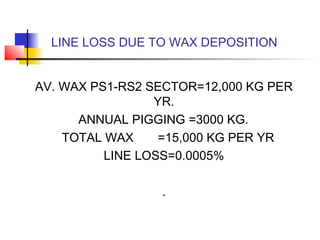

This document discusses pipeline line loss, which is the difference between the quantity of crude oil at the off take and delivery ends of a pipeline. It identifies the key factors that influence line loss, including measurement errors related to tank dip, temperature, density, and water content. Other factors like evaporation, wax deposition, and pilferage are also discussed. The document analyzes line loss data from several pipelines in India and North America over multiple years and the impact of factors like water content, measurement errors, and wax deposition. It outlines steps taken to improve measurement uniformity and control water to reduce line losses.