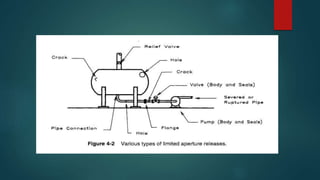

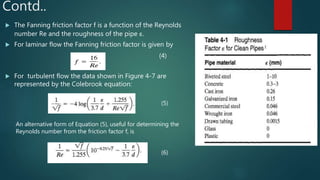

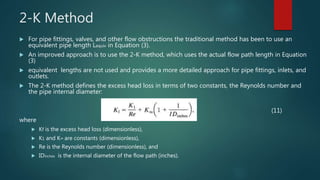

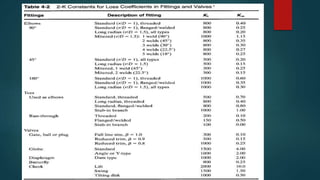

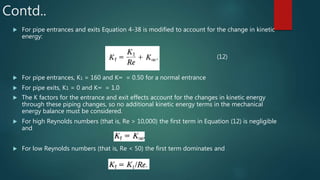

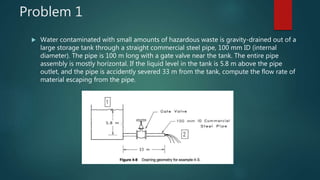

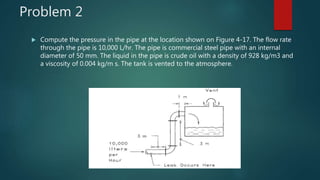

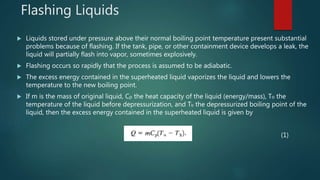

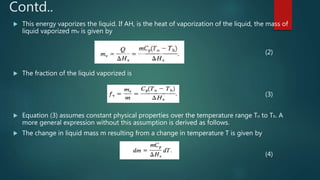

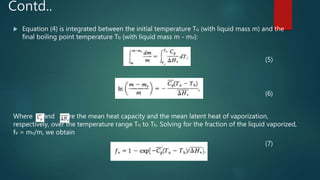

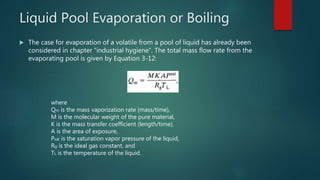

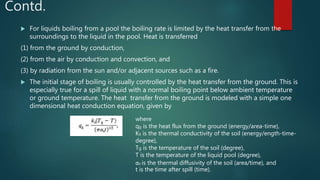

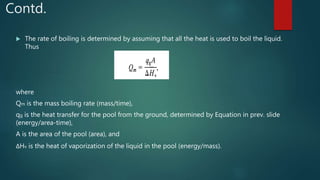

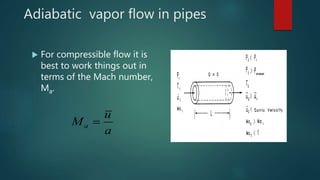

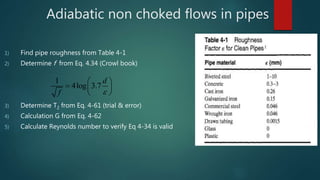

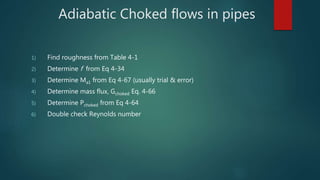

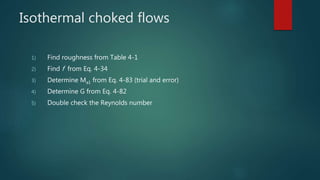

This document provides information on source models used to describe the discharge of materials from industrial process accidents. It discusses several basic source models including the flow of liquids through pipes. The key equations for modeling pipe flow are presented, including the mechanical energy balance equation and equations for determining friction factors and head losses. Solution procedures for calculating the mass flow rate discharged from a piping system are outlined. Additional source models covered include flashing liquids, liquid pool evaporation, and vapor flow through pipes under both adiabatic and isothermal conditions.