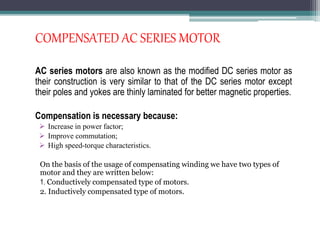

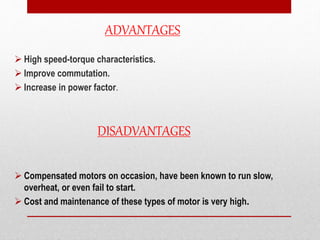

This document presents a report on single phase compensated motors. It begins with an introduction to compensated windings which are used to address problems with commutation in AC machines. It then discusses commutation, compensation, and the different types of compensated AC motors including series, universal, and repulsion motors. The key advantages of compensation are improved power factor, commutation, and speed-torque characteristics. While compensated motors have higher costs, they provide benefits like higher starting torque, efficiency, and longevity that outweigh their additional expenses. In conclusion, compensated motors are recommended for heavy duty applications in industries.

![TECHNOINDIA, SALTLAKE

DEPARTMENT OF ELECTRICAL ENGINEERING

ELECTRICAL MACHINE-II [EE-501]

SUBMITTED BY:

• SPANDAN PAUL (ROLL: 13001616037)

• SOURADEEP MULLICK (ROLL: 13001616038)

• SIDDHARTHA BASU (ROLL: 13001616042)

• SHAKYA ACHARYA (ROLL: 13001616046)

• SAYANTAN KUMAR CHATTOPADHYAY (ROLL: 13001616047)

• SAYAN SARKAR (ROLL:13001616049)](https://image.slidesharecdn.com/singlephasecompensatedmotor-190508074916/85/Single-phase-compensated-motor-1-320.jpg)