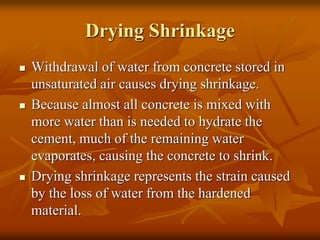

This document contains information about different types of shrinkage and creep that can occur in concrete. It discusses drying shrinkage, which occurs as water evaporates from concrete, causing it to shrink. Plastic shrinkage occurs while the concrete is still fresh and can cause cracking. Factors that influence each type of shrinkage are provided. The document also introduces creep, which is the slow deformation of concrete under stress over a long period of time. Consequences of creep such as loss of pre-stress and excessive deflection are mentioned.