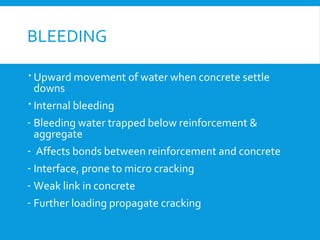

This document discusses various types and causes of cracks in buildings. It classifies cracks as either structural or non-structural and further categorizes them based on their width. Common causes of cracks include moisture movement, thermal variation, excessive loading, and foundation settlement. Plastic shrinkage, bleeding, delayed curing, and use of poor quality materials can lead to cracks in concrete before it hardens. Thermal expansion and contraction from temperature changes is another major cause of cracks. Various remedial measures are proposed to prevent or reduce cracking in structures.