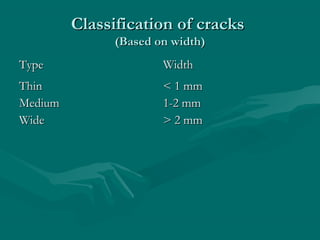

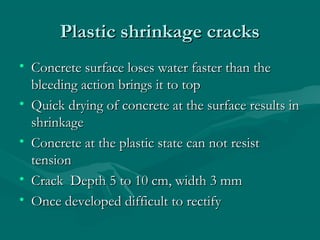

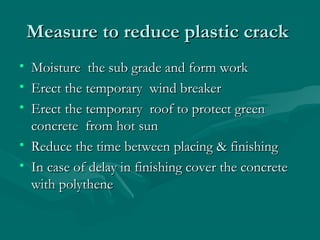

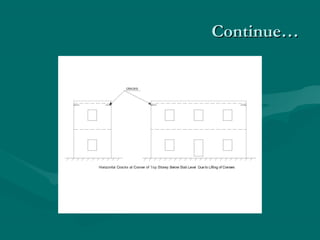

This document discusses cracks in buildings and their causes and remedies. It begins by noting that determining the severity of cracks is difficult. Cracks are classified as structural or non-structural based on their cause. Reasons for cracks include chemical reactions, climate, foundation issues, and material quality. Cracks are also classified by width as thin, medium, or wide. The document outlines various types of cracks in concrete and their causes such as plastic shrinkage, bleeding, drying, and thermal expansion. It provides measures to prevent or repair cracks through drainage, construction practices, and curing concrete properly.