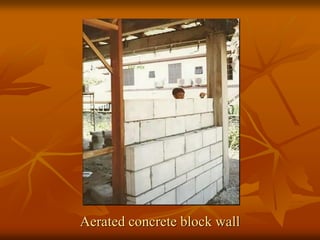

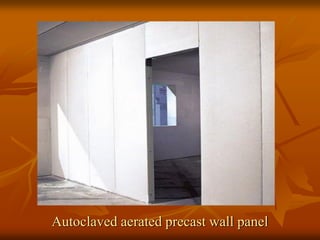

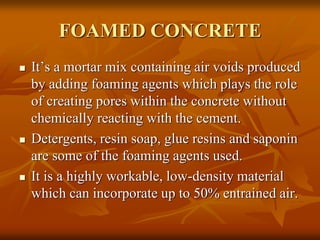

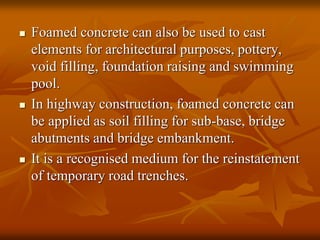

Lightweight concrete has a density not exceeding 1850kg/m3. There are three main types: aerated concrete made through chemical reactions or foaming agents, no fines concrete which omits fine aggregates, and lightweight aggregate concrete using materials like pumice. Aerated concrete is popular in Europe due to its lightness and versatility. It is made through introducing gas into a cement-sand mix using chemicals or foaming agents. Foamed concrete uses foaming agents to create air voids without chemical reactions. Both have advantages like lower density, strength, and cost. They are used in construction for walls, panels, foundations, and other structural and non-structural purposes.