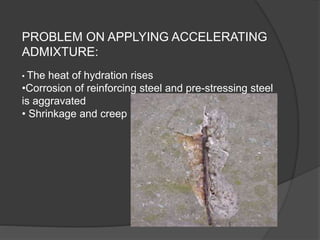

Concrete is a common construction material whose properties can be predetermined through design. Key properties include strength, durability, elasticity, shrinkage, creep, and impermeability. Strength is the most important hardened concrete property and is affected by factors like curing conditions, cement type and composition, water-cement ratio, aggregate type and size, and void content. Shrinkage occurs as water leaves the concrete, causing cracks, while creep is permanent deformation under stress over long periods. Proper use of reinforcement, joints, and cement composition can reduce cracking from these effects.

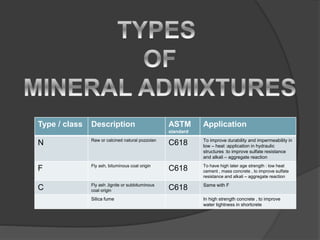

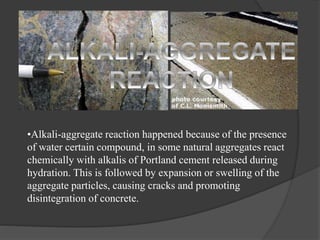

![Mineral admixtures (fly ash, silica fume [SF], and slags)

are usually added to concrete in larger amounts to

enhance the workability of fresh concrete; to improve

resistance of concrete to thermal cracking, alkali-

aggregate expansion, and sulfate attack; and to enable

a reduction in cement content](https://image.slidesharecdn.com/concrete-230225132523-08f12f20/85/Concrete-pptx-59-320.jpg)