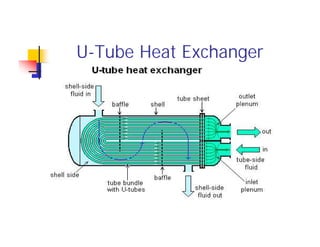

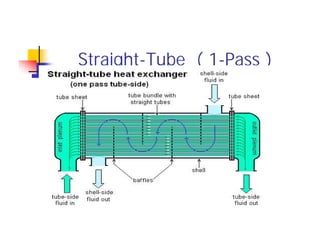

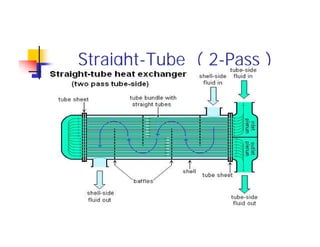

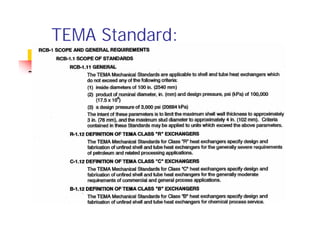

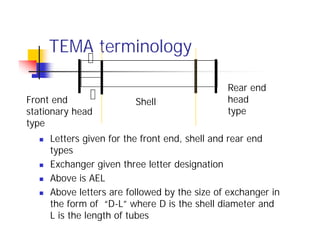

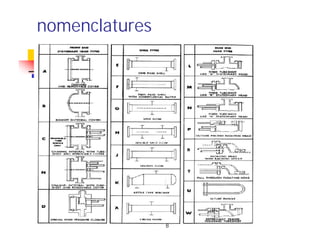

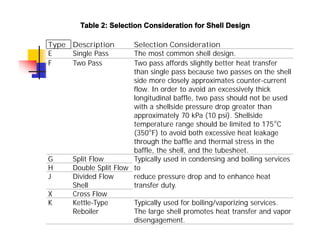

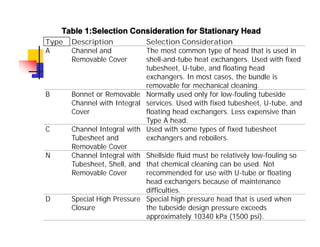

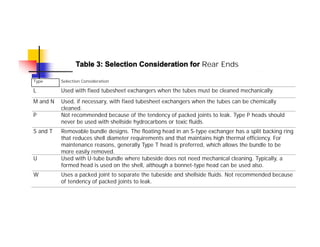

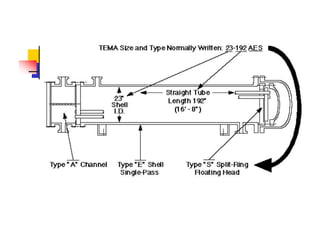

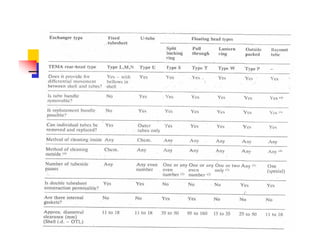

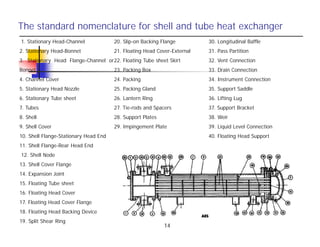

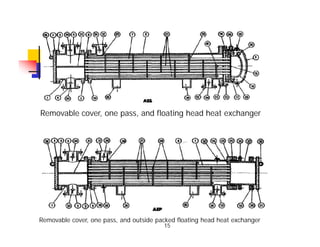

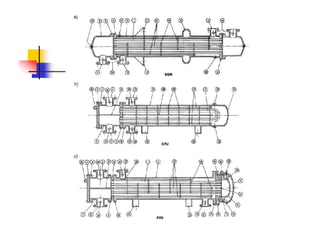

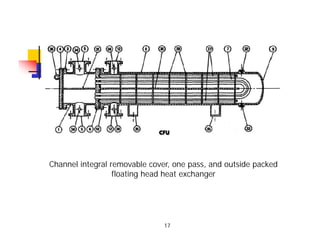

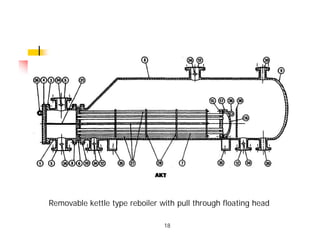

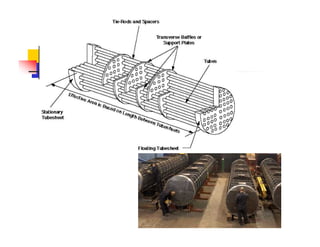

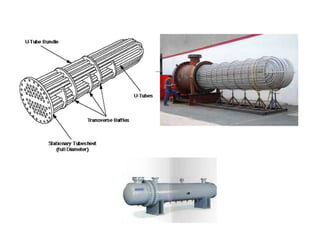

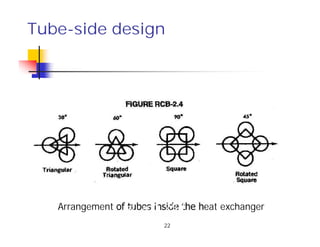

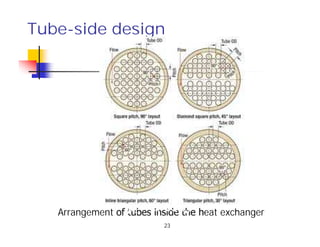

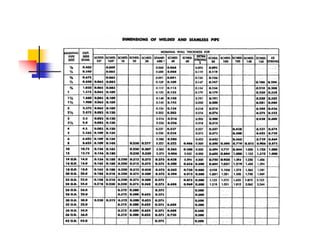

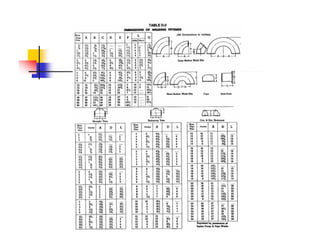

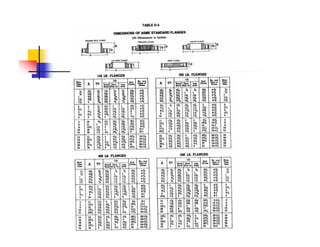

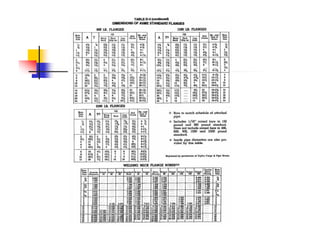

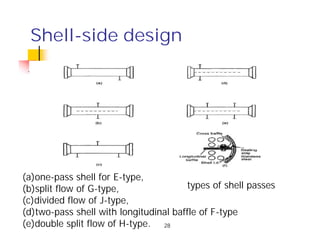

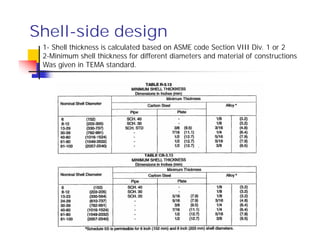

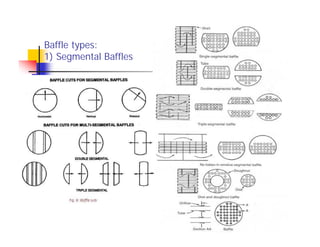

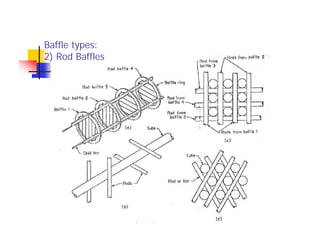

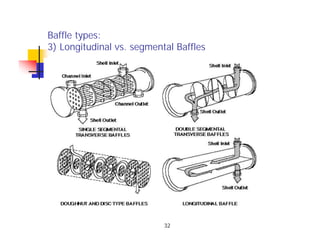

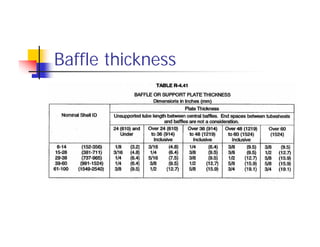

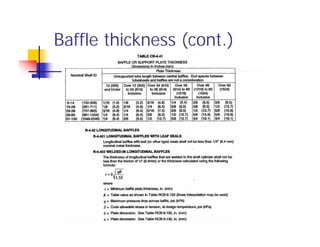

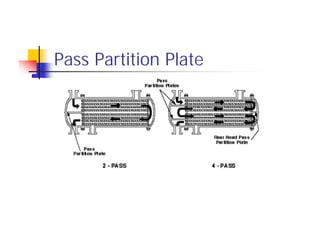

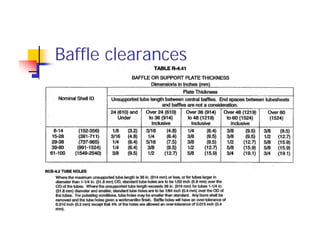

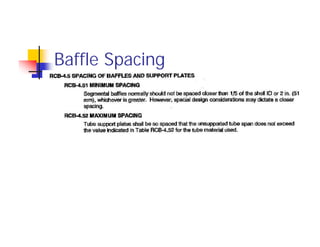

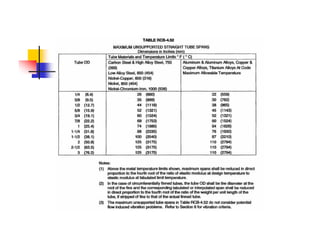

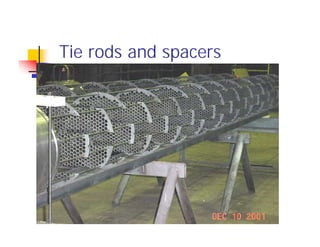

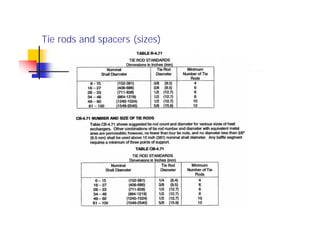

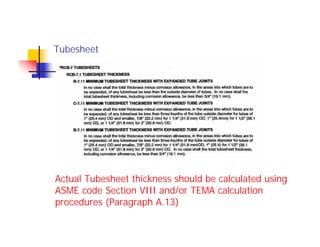

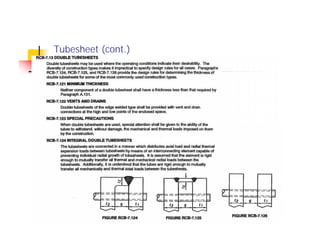

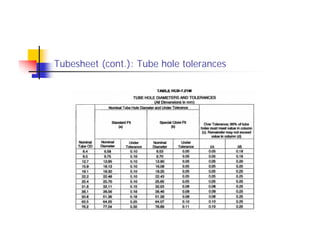

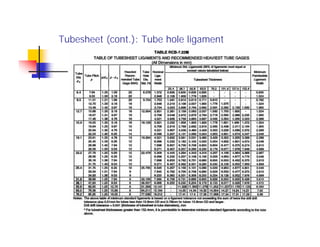

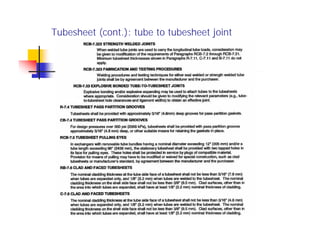

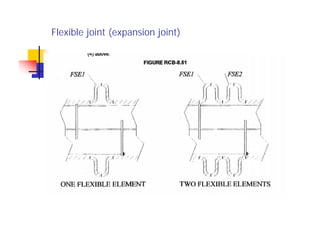

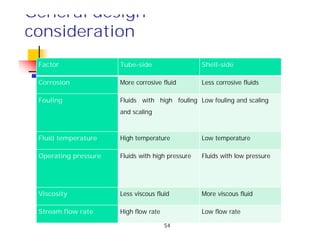

The document discusses shell and tube heat exchangers. It describes the different types of shell and tube designs according to the TEMA standard, including U-tube, straight tube, and kettle-type designs. It also discusses design considerations for different components like stationary heads, rear ends, baffles, tubesheets, and joints. The TEMA standard provides terminology for naming heat exchangers based on these design features and components.