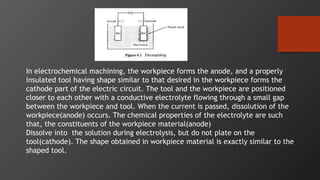

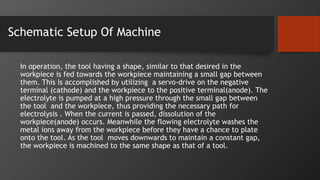

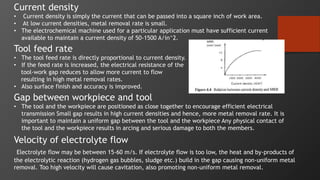

Electrochemical machining is a non-traditional machining process that removes metal by an electrochemical process. It works based on Faraday's laws of electrolysis by passing a current between an electrode tool and a metal workpiece separated by an electrically conductive fluid. The workpiece acts as the anode and dissolves as metal ions are carried away from the gap by the flowing electrolyte. Key process parameters include current density, tool feed rate, electrolyte flow velocity, and gap size, which control the metal removal rate. ECM can machine hard metals and complex shapes with good surface finish and no tool wear. Its applications include die sinking, drilling turbine blades, and micro machining.