This document discusses different types of sewing threads, their properties, and uses. It covers the following key points:

1. Sewing threads are classified as cotton threads or synthetic threads, with cotton having good strength but low extensibility, and synthetics having high strength and adjustable extensibility.

2. Important properties of sewing threads include sewability, tensile strength, abrasion resistance, resistance to high temperatures, and colorfastness.

3. Thread ticket numbers indicate the thread thickness - cotton is based on single yarn count while metric is based on single yarn count and number of plies.

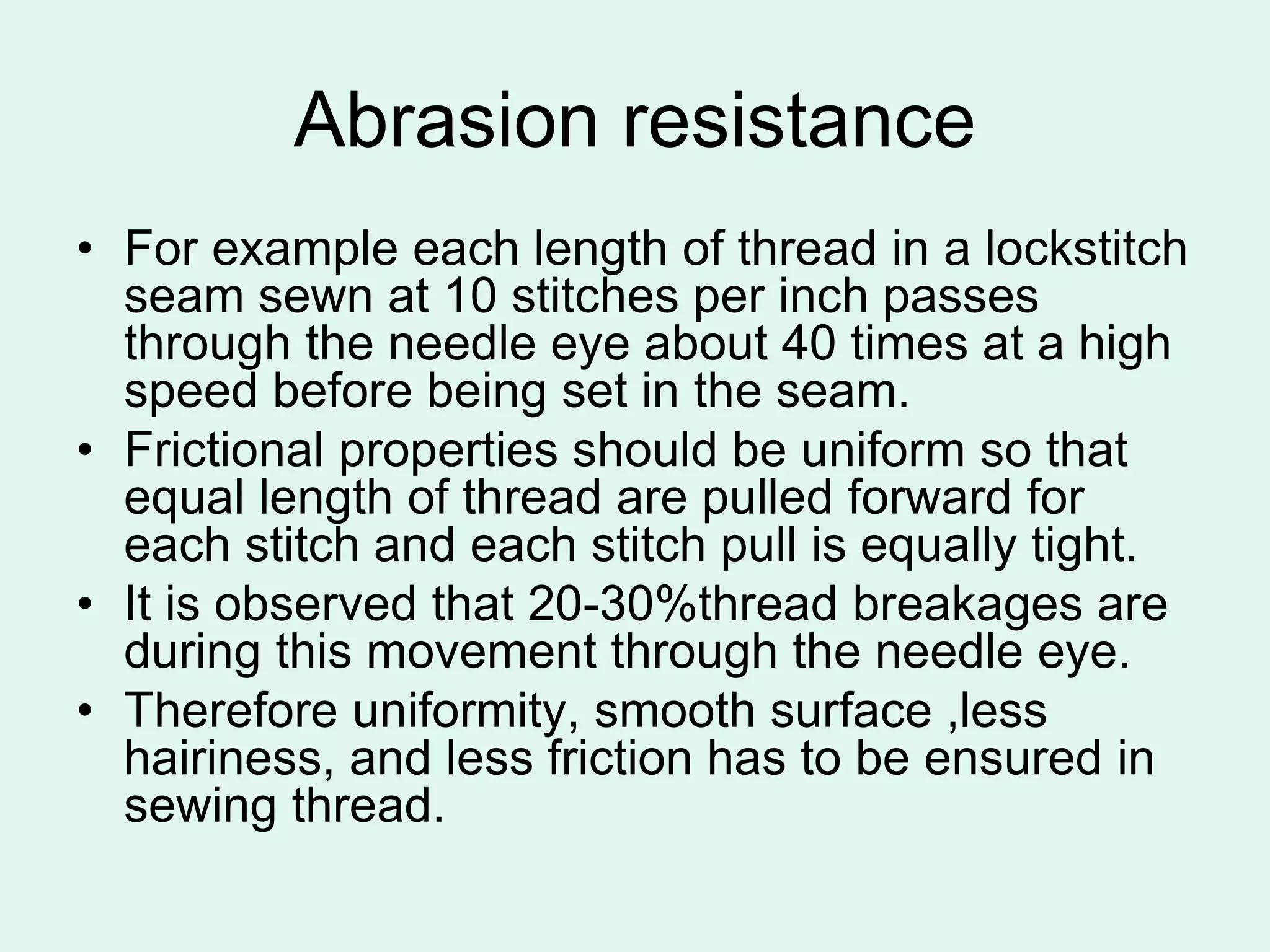

4. Different types of sewing threads are used for various end uses like ready-made

![Sewing threads and its

properties

By

k. chandran, Ts[p], IHTTKerala.](https://image.slidesharecdn.com/sewingthreadsanditsproperties-201029165606/75/Sewing-threads-and-its-properties-1-2048.jpg)

![Thread performance

• Thread must ensure satisfactory

performance in the seam. It is expressed

by seam efficiency index [SEI].

• seam tensile strength

• SEI= ------------------------------ x 100

• fabric tensile strength](https://image.slidesharecdn.com/sewingthreadsanditsproperties-201029165606/75/Sewing-threads-and-its-properties-7-2048.jpg)

![9. Hosiery threads Cotton soft 40,60.

10

.

Embroidery threads,

crochet ,tatting, etc..

Cotton gm 25 [12/31]

20 [6/24]

40 [6/40].

11

.

Machine embroidery

threads

---- do ----&

Rayon's

50

120 dx2

12 Zippers stitching Continuous

polyester

filament

120,180.](https://image.slidesharecdn.com/sewingthreadsanditsproperties-201029165606/75/Sewing-threads-and-its-properties-19-2048.jpg)