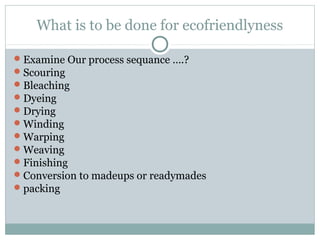

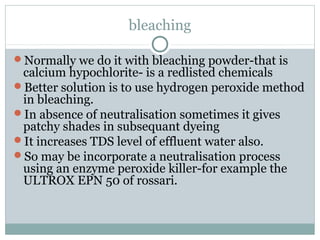

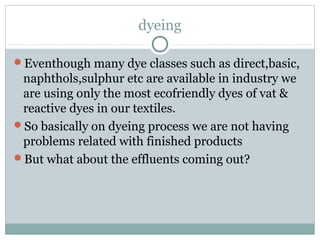

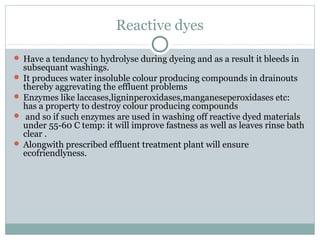

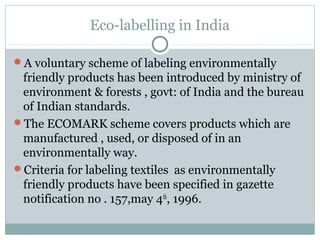

This document discusses eco-friendly dyeing processes and eco-labeling. It defines what makes a product eco-friendly, including limiting harmful chemicals and minimizing pollution. The government of India has banned certain dyes and chemicals containing amines. Requirements for eco-friendly textiles include the absence of banned chemicals and heavy metals, and low levels of formaldehyde. The document then discusses how to make various textile production processes like scouring, bleaching, dyeing and finishing more environmentally friendly, for example by using enzymes. It also covers eco-labeling schemes in India to identify environmentally friendly textile products for consumers.

![BY

K.CHANDRAN, TECH:SUPDT:[P],

IIHTKANNUR.

Eco friendly dyeing process and

eco- labeling](https://image.slidesharecdn.com/ecofriedlydyeingprocessandecolabels-150102231732-conversion-gate01/75/Ecofriedly-dyeing-process-and-ecolabels-1-2048.jpg)

![Requirements for ecofriendlyness

Absence of banned amines or amine releasing

agents in textiles.

Very low levels of [such as below 30ppm] of

formaldehyde in different uses in textiles.

Absence of chlorinated compounds.

Extremely low levels of heavy metals such as

mercury,cadmium,copper,nickel,cobalt,arsenic,lea

d, chromium etc:](https://image.slidesharecdn.com/ecofriedlydyeingprocessandecolabels-150102231732-conversion-gate01/85/Ecofriedly-dyeing-process-and-ecolabels-3-320.jpg)

![List of chemicals

Chlorinated compounds

Formaldehyde

Sodium sulphide

Penta chlorophenol[pcp]

Dibutyl phthalate

Tributyl phosphate

Nonyphenol ethoxylate

Dichloro toluene

Trichloro benzene

DDT, ALDRIN,DIALDRIN,ENDRIN ETC:](https://image.slidesharecdn.com/ecofriedlydyeingprocessandecolabels-150102231732-conversion-gate01/85/Ecofriedly-dyeing-process-and-ecolabels-5-320.jpg)

![scouring

This is the process of removing chemical

impurities from the raw material-the yarn

Conventionally we do it with boiling yarn using

caustic soda+soda ash+soap oil[or any detergent]

in vomitting kiers.

This increases BOD,COD levels of effluent water

If enzyme scouring is used this problem can be

avoided.protease,pectinase,lipase etc: are

examples.

Scourenz SBWB is such a product from rossari](https://image.slidesharecdn.com/ecofriedlydyeingprocessandecolabels-150102231732-conversion-gate01/85/Ecofriedly-dyeing-process-and-ecolabels-7-320.jpg)

![Major criteria for eco-labeling

Levels of pH.

Low permissible levels of formaldehyde.

Restriction on use of certain pesticides.

Extremely low levels of some heavy metals.

Prohibition on pentachlorophenol [PCP].

Absence of chlorinated , aliphatic/aromatic

compounds.

Absence of azo dyes which can liberate any one of

the 21 banned arylamines listed by German govt:](https://image.slidesharecdn.com/ecofriedlydyeingprocessandecolabels-150102231732-conversion-gate01/85/Ecofriedly-dyeing-process-and-ecolabels-17-320.jpg)

![Types of eco labels

There are two types of ecolabeling demands from

consumers point of view.

1. ecological and biological textiles [that is fully

natural textiles].

2. ecologically optimized textile products [green

products].](https://image.slidesharecdn.com/ecofriedlydyeingprocessandecolabels-150102231732-conversion-gate01/85/Ecofriedly-dyeing-process-and-ecolabels-18-320.jpg)