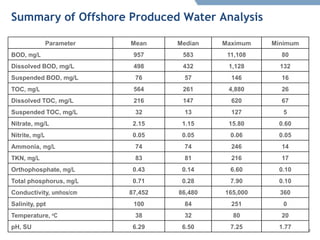

Offshore oil and gas production in the Gulf of Mexico generates large volumes of produced water. Nearly 91% of the 587,353 barrels per day of produced water from offshore wells is treated on platforms and discharged into the ocean, as regulated by NPDES permits. A variety of physical, chemical, and biological treatment technologies are used to clean produced water before discharge to meet permit limits for oil and grease.