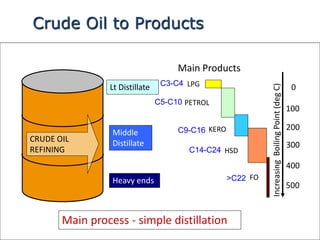

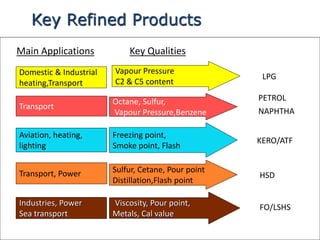

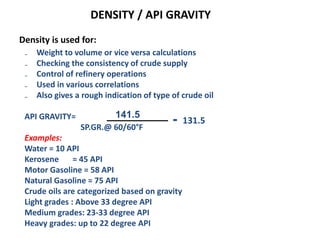

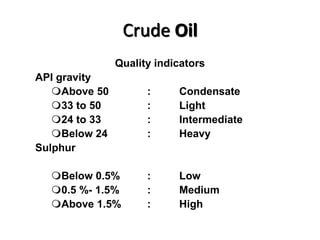

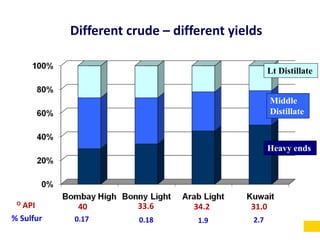

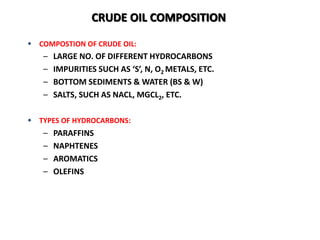

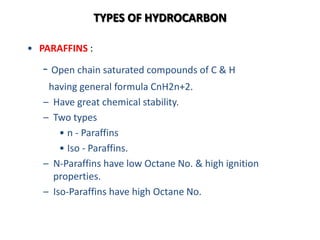

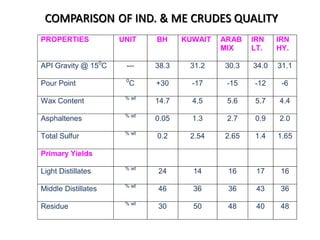

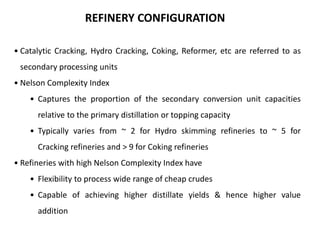

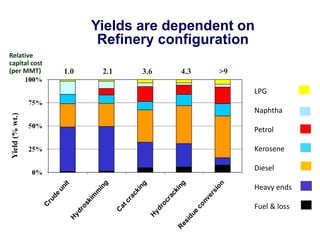

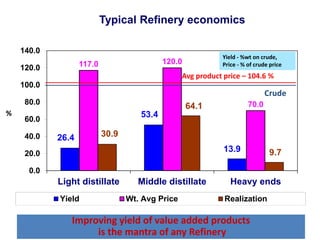

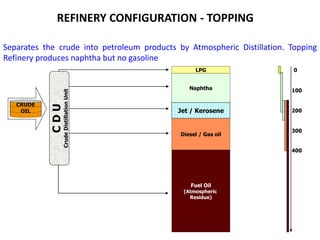

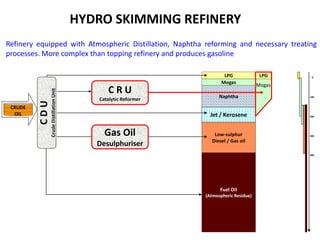

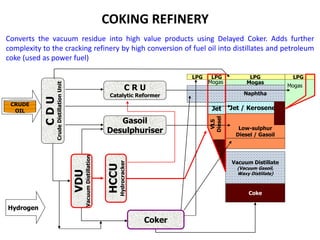

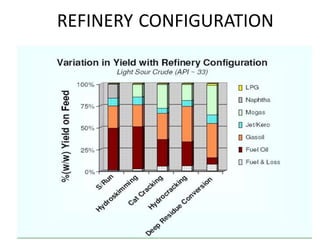

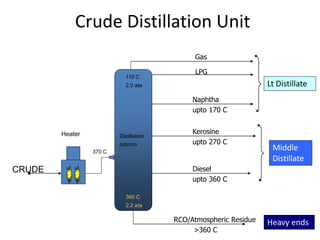

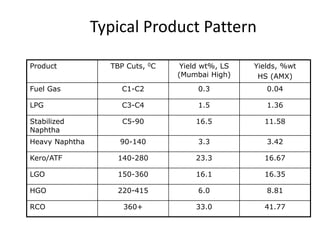

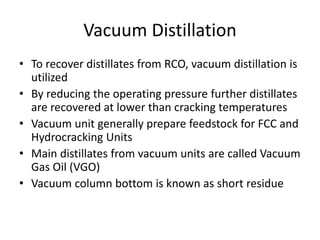

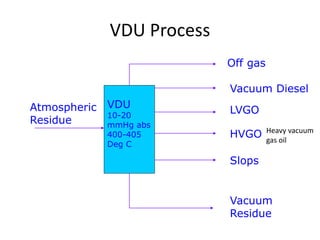

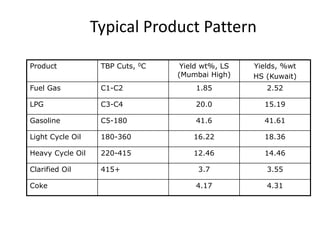

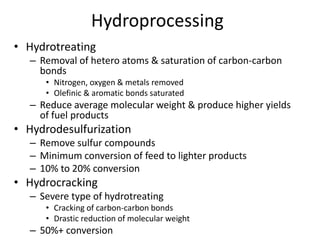

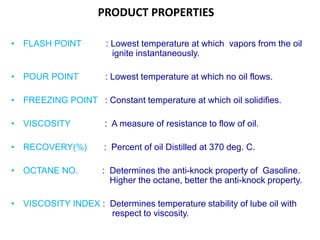

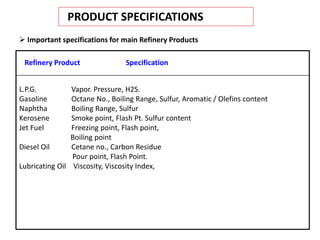

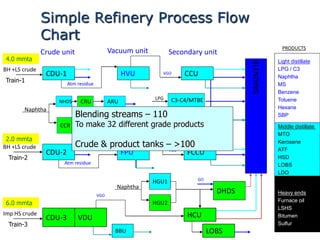

The document provides a comprehensive overview of the history and processes involved in petroleum refining, highlighting the evolution from early kerosene production to modern complex refineries. It details the types of hydrocarbons present in crude oil and their classifications, as well as various refining processes used to convert crude into valuable products. Additionally, it discusses the economic considerations and configurations of refineries that affect product yields, including atmospheric and vacuum distillation.