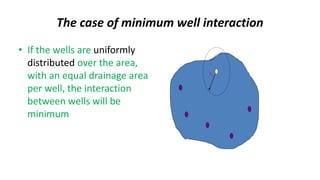

This document discusses key principles of gas field development planning. It explains that gas properties like compressibility require a direct relationship between the reservoir, wells, pipelines, and consumers. Development considers the gas drive mechanism, well spacing patterns to optimize drainage areas, withdrawal rates based on pipeline capacity and demand, and economics involving recovery factors, costs, and productive lifetime. The compressorless and compressor periods of exploitation are also outlined.