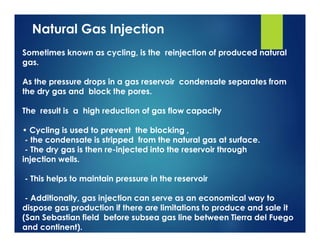

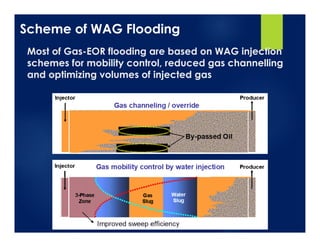

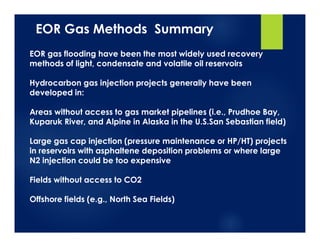

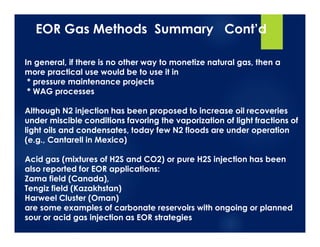

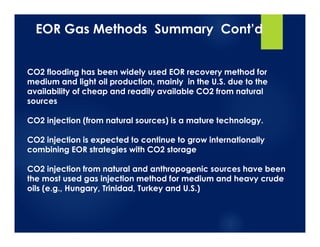

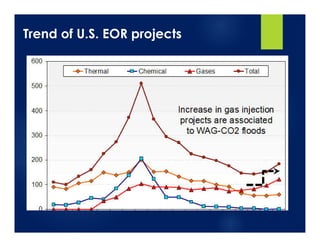

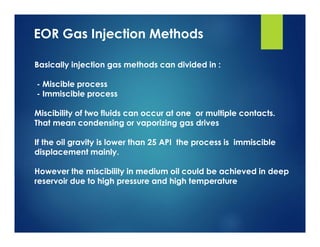

This document provides an overview of enhanced oil recovery (EOR) methods using gas injection. It discusses the main gas injection methods including miscible and immiscible processes. Key injection gases are carbon dioxide (CO2), nitrogen (N2), and natural gas. CO2 flooding has been widely used in the US and offers potential for combining EOR with CO2 storage. Economics of CO2-EOR and carbon capture and storage (CCS) are also reviewed. While gas injection is common, the number of N2 flood projects has declined with most current EOR relying on natural gas or CO2 if it is available. Offshore, EOR potential exists but is currently limited to gas and water-alternating-

![Gas injection has been considered almost exclusively as a

pressure maintenance for light and medium crude oil

(generally > 25 API) reservoirs

Injection Strategies depends on

- geological structure of reservoir(

high dip angle : use up dip injection [gravity stable floods]

low dip angle : analyze completion strategy or use WAG

If Co2 or Nitrogen (N2) injection is possible, then gas could be

used to produce energy or gas market.

EOR Gas Methods](https://image.slidesharecdn.com/4-eor4gasmethods-180113184248/85/4-eor-4-gasmethods-4-320.jpg)