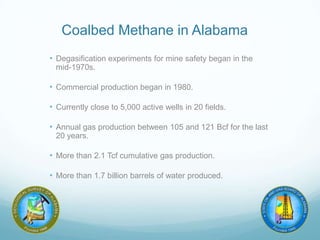

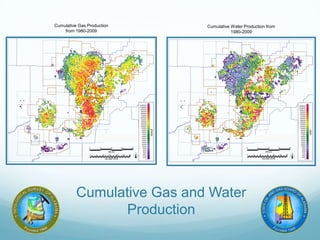

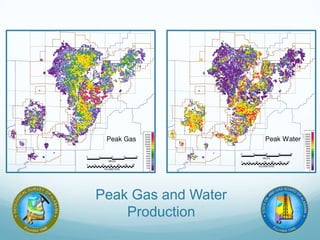

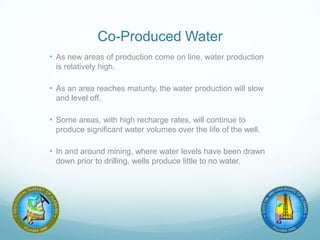

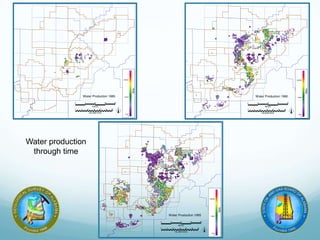

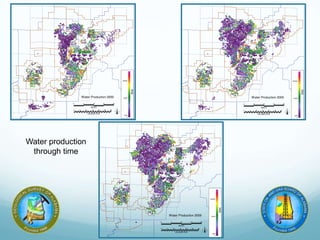

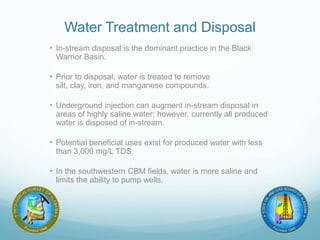

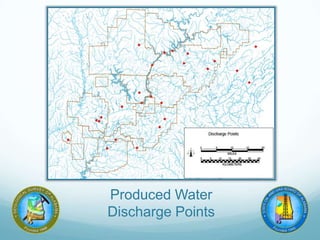

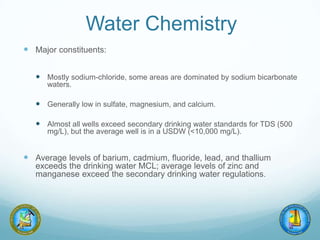

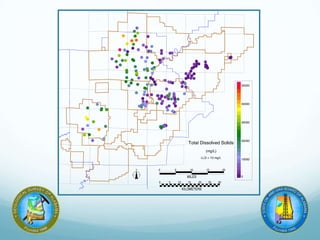

This document summarizes characteristics of coalbed methane produced water in Alabama. It notes that over 1.7 billion barrels of water have been produced from nearly 5,000 active coalbed methane wells in Alabama. The water is typically brackish and high in sodium and chloride. While in-stream disposal is most common, there is potential to beneficially use the water for aquaculture, irrigation, drilling, or municipal supply with additional treatment.