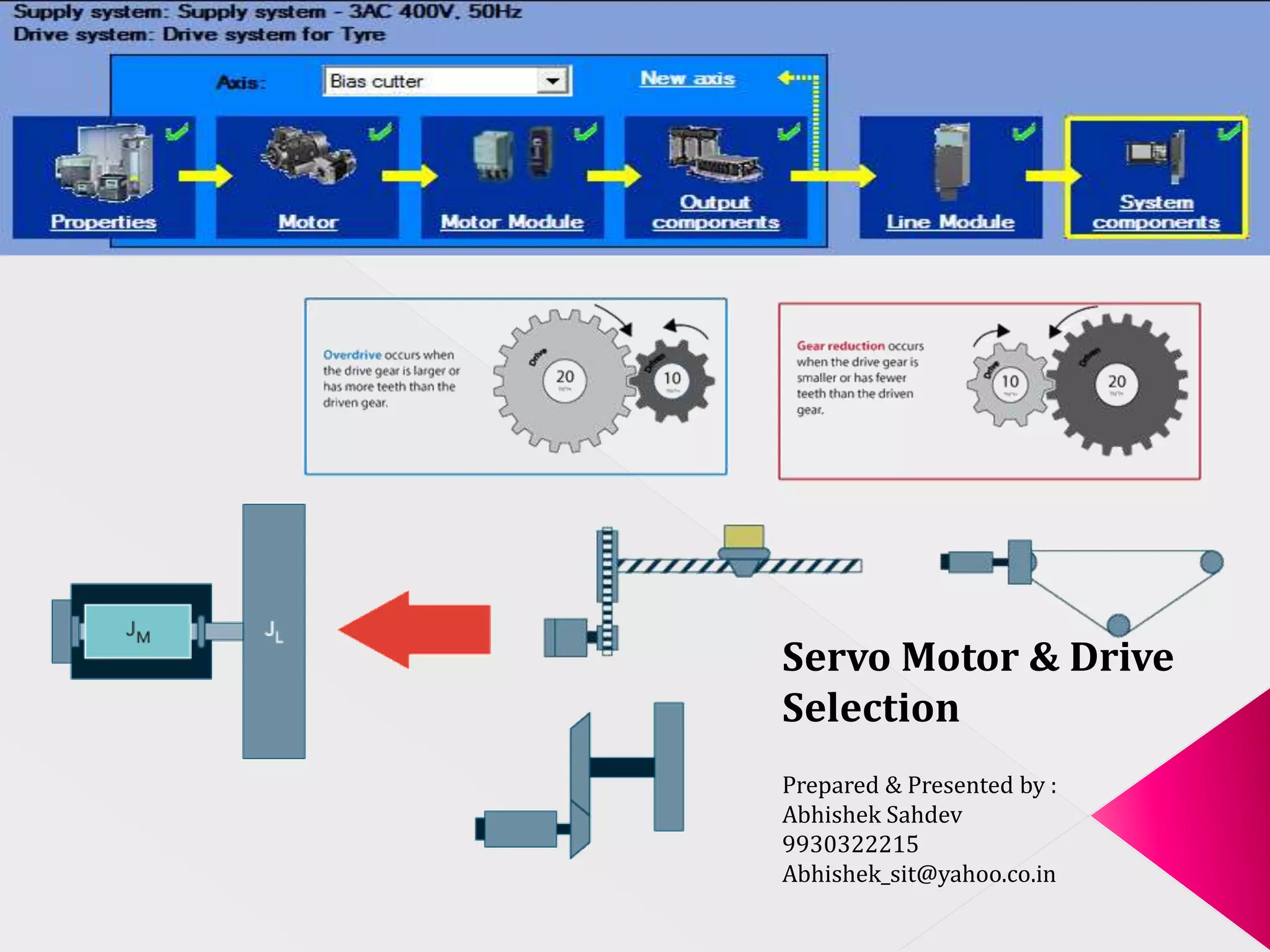

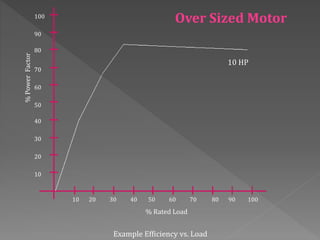

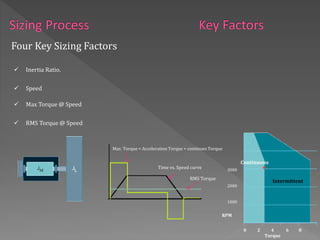

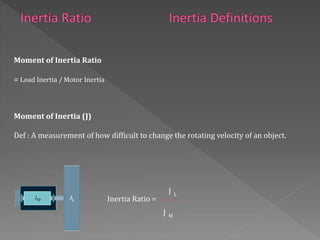

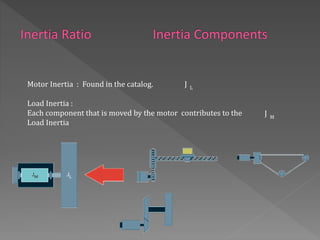

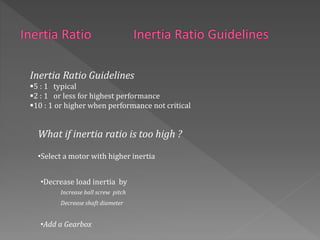

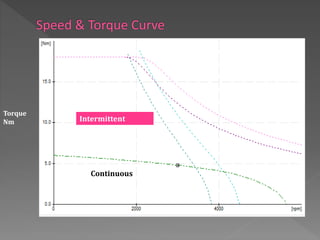

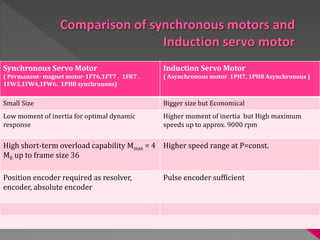

This document discusses factors to consider when selecting a servo motor and drive for an application. It outlines key sizing factors like inertia ratio, speed, maximum torque at speed, and RMS torque at speed. An inertia ratio between 2:1 and 5:1 is typical, with higher ratios requiring a motor with more inertia or changes to reduce load inertia. It also provides information on synchronous vs induction servo motors and their relative advantages. In general, a modest motor oversizing of up to 20% is acceptable.