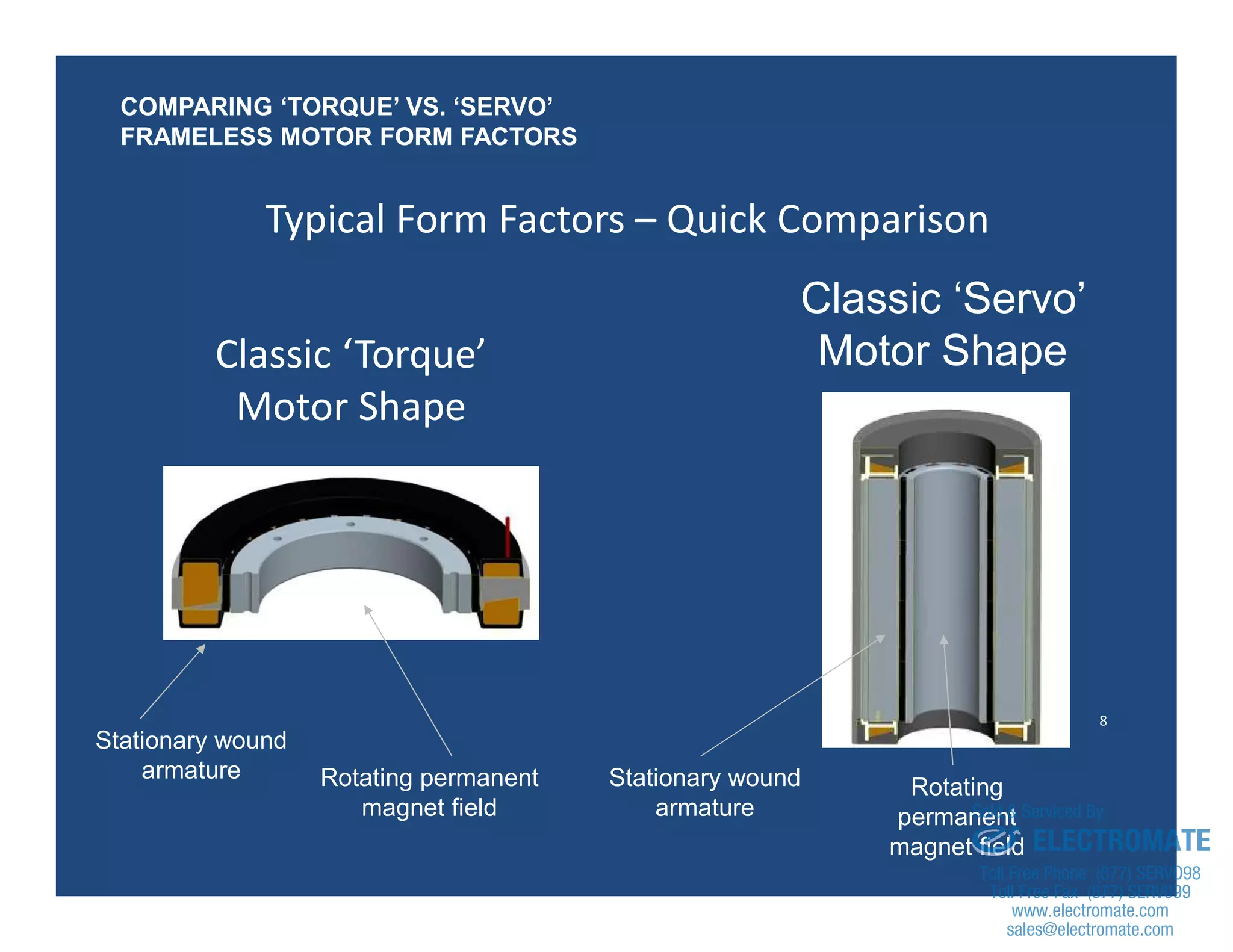

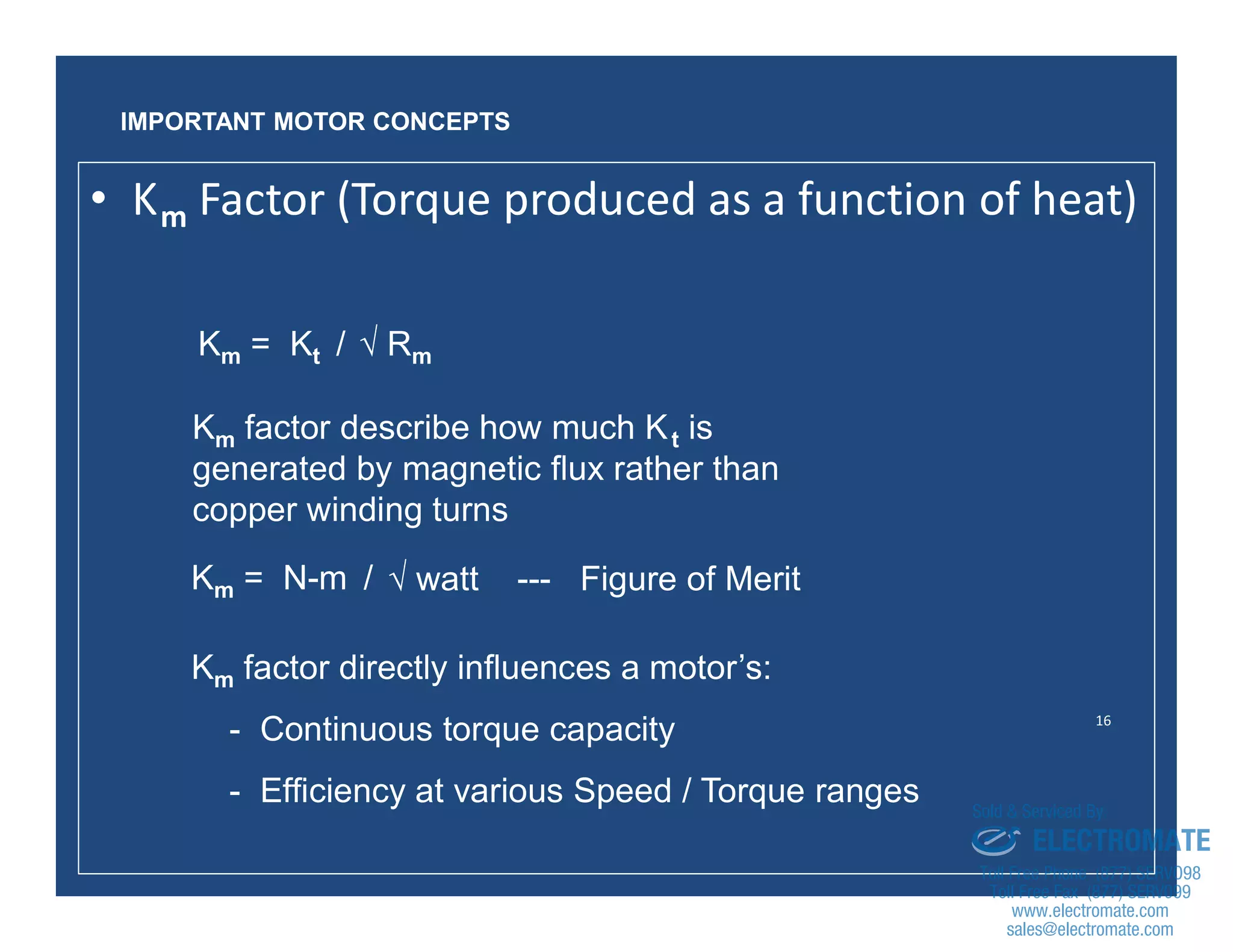

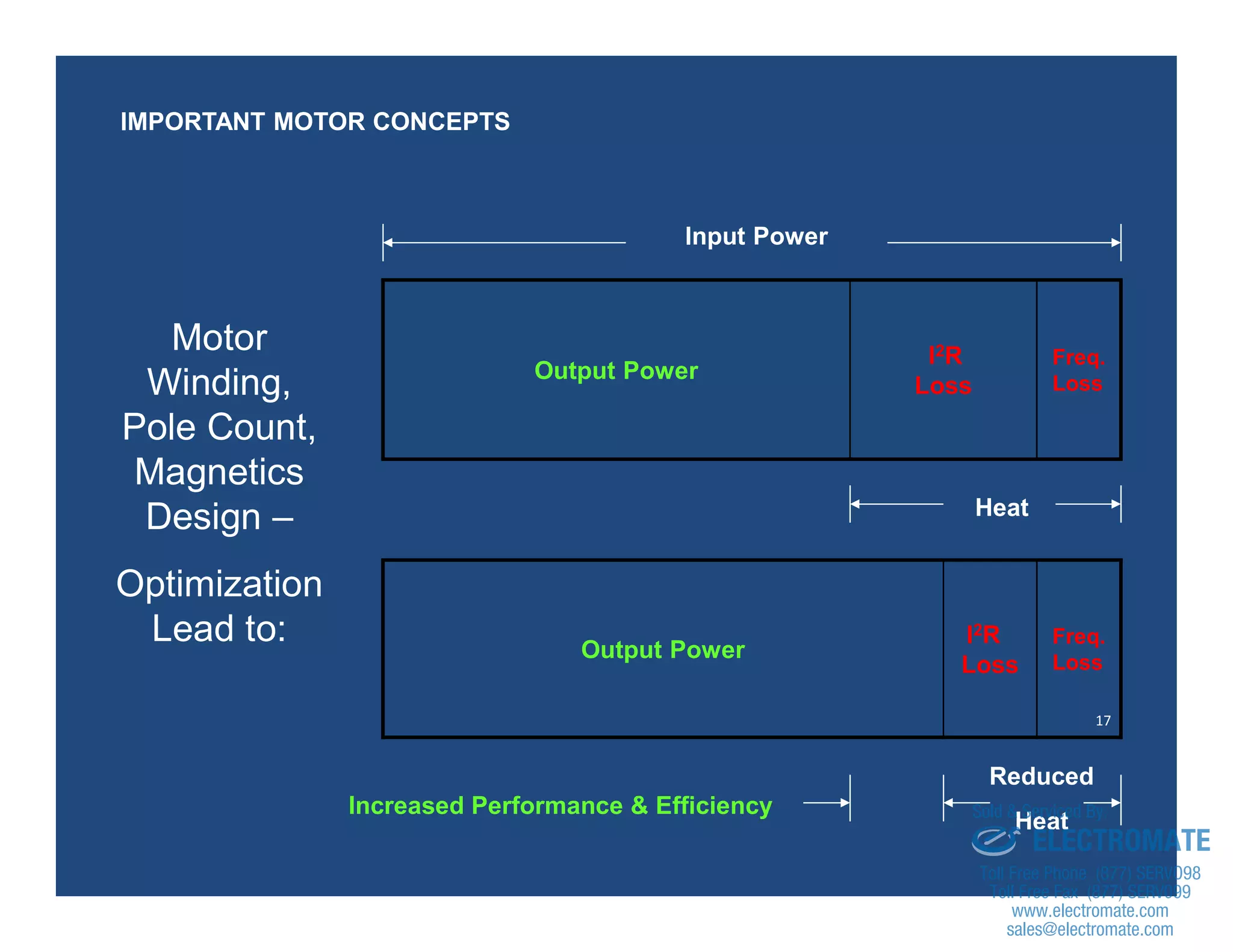

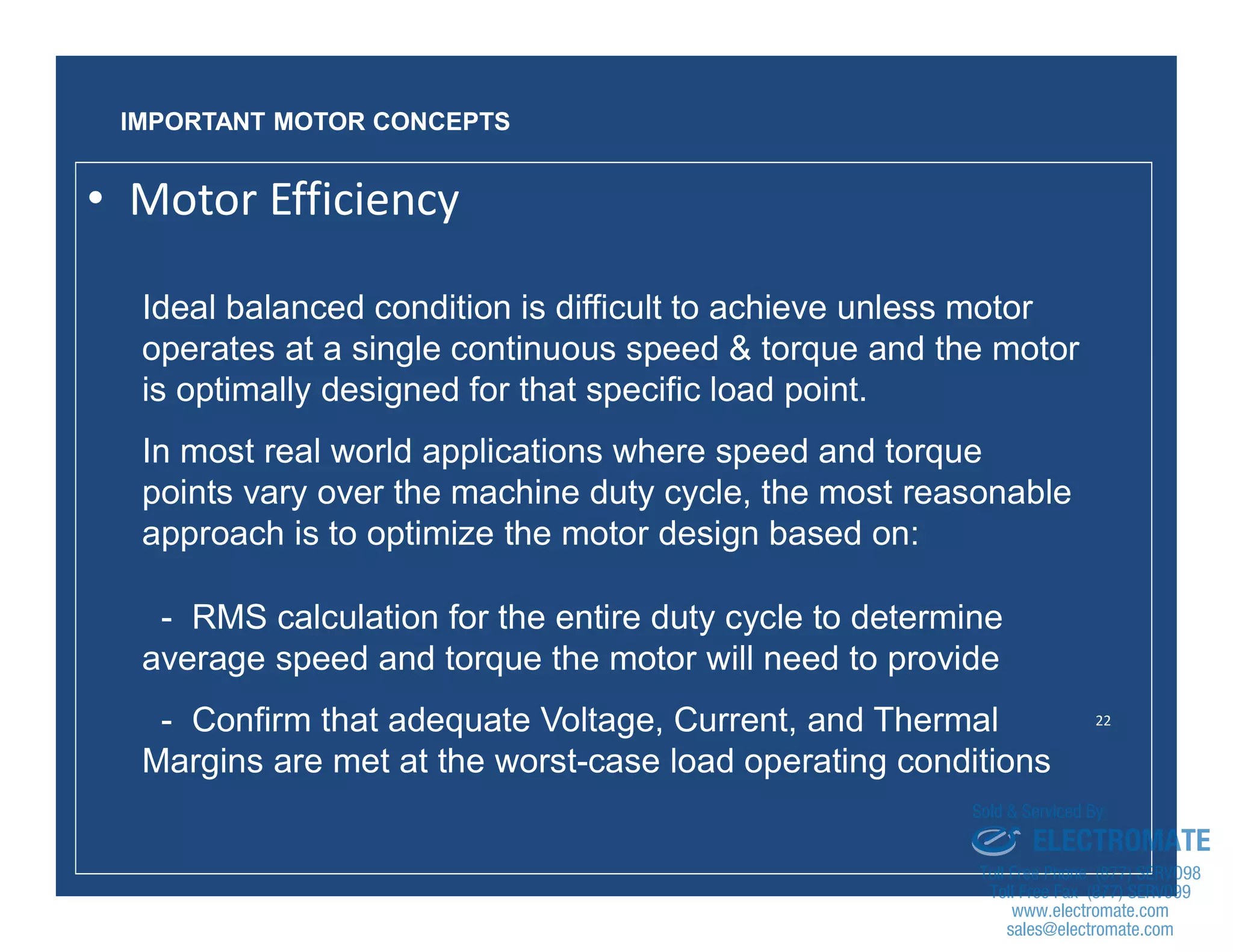

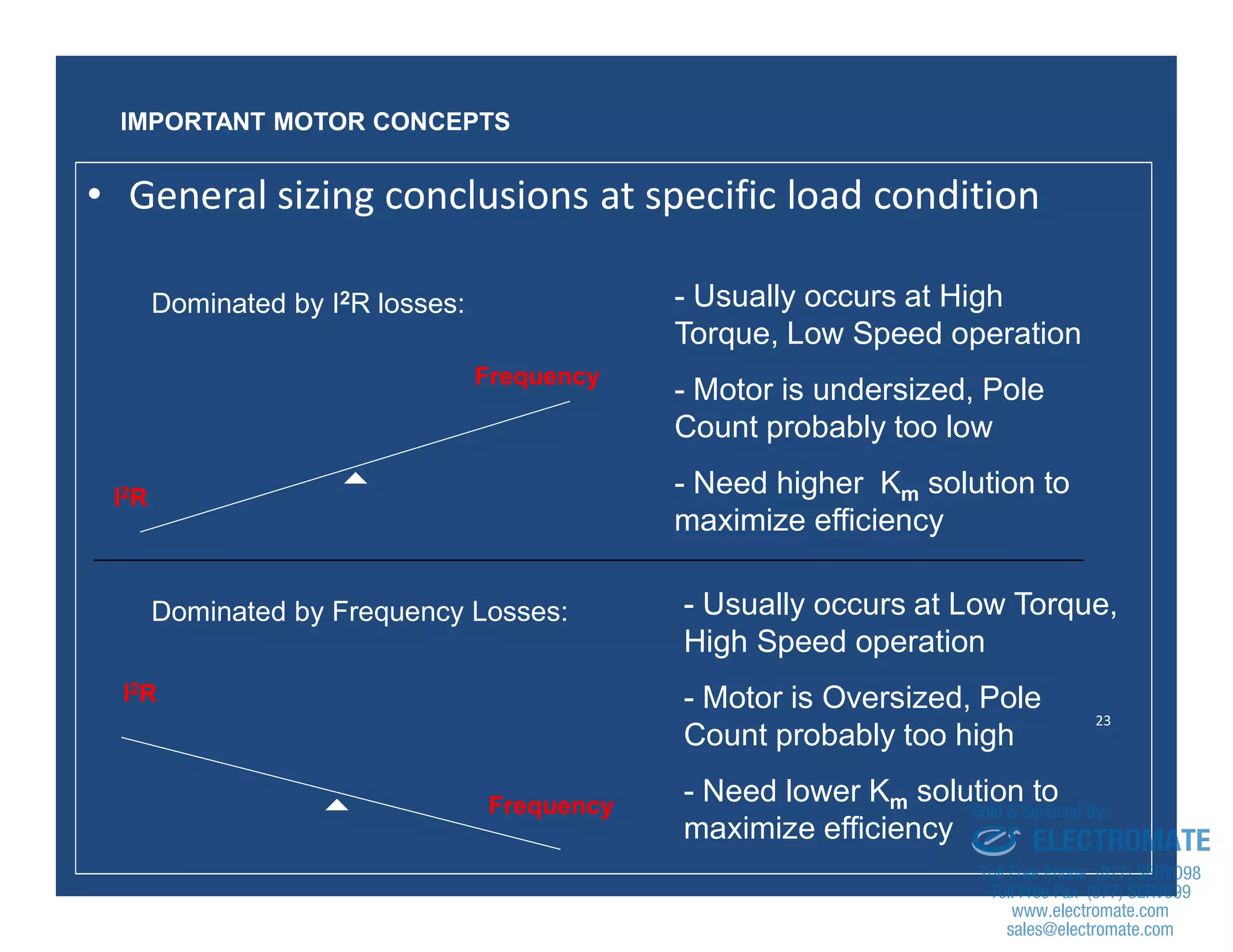

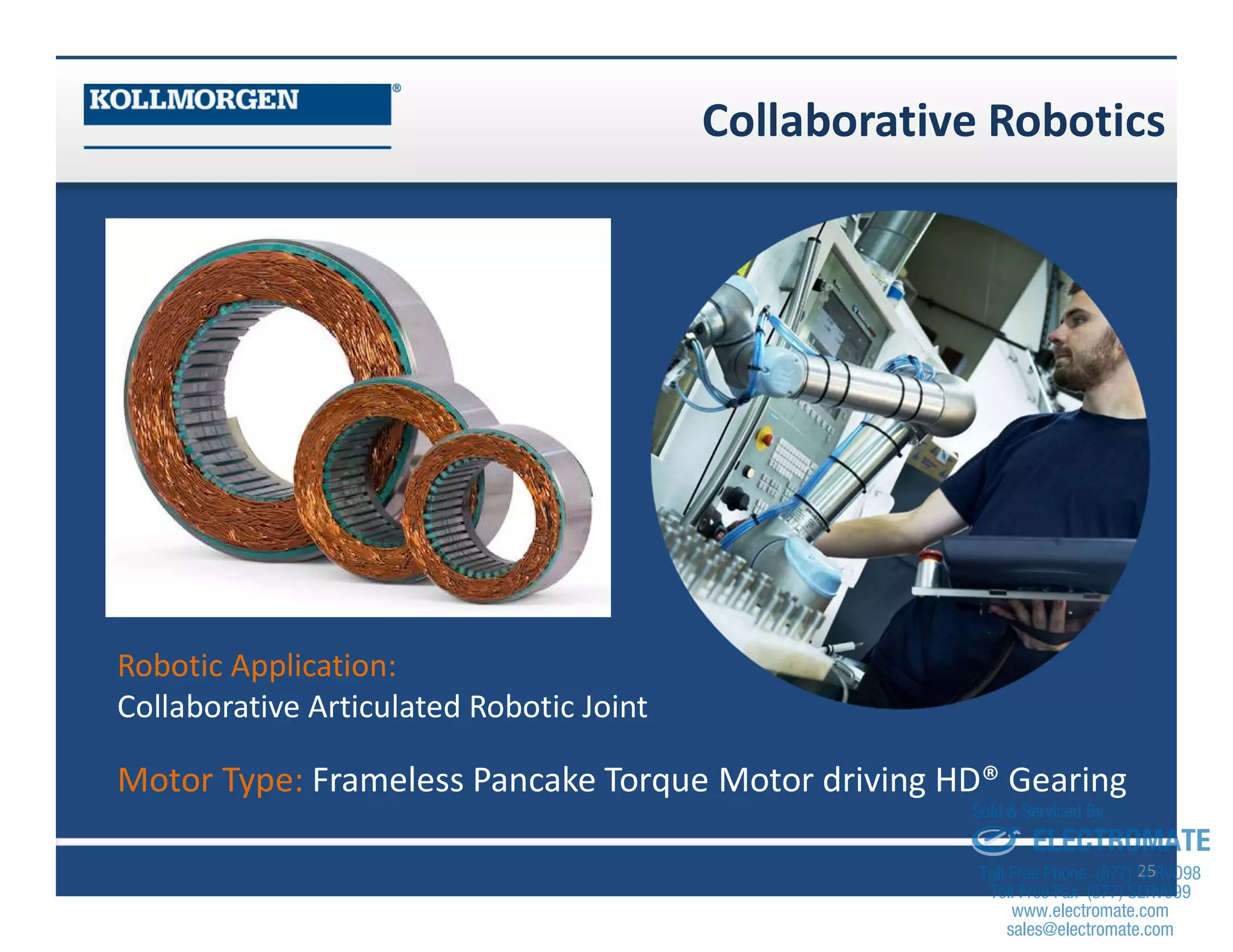

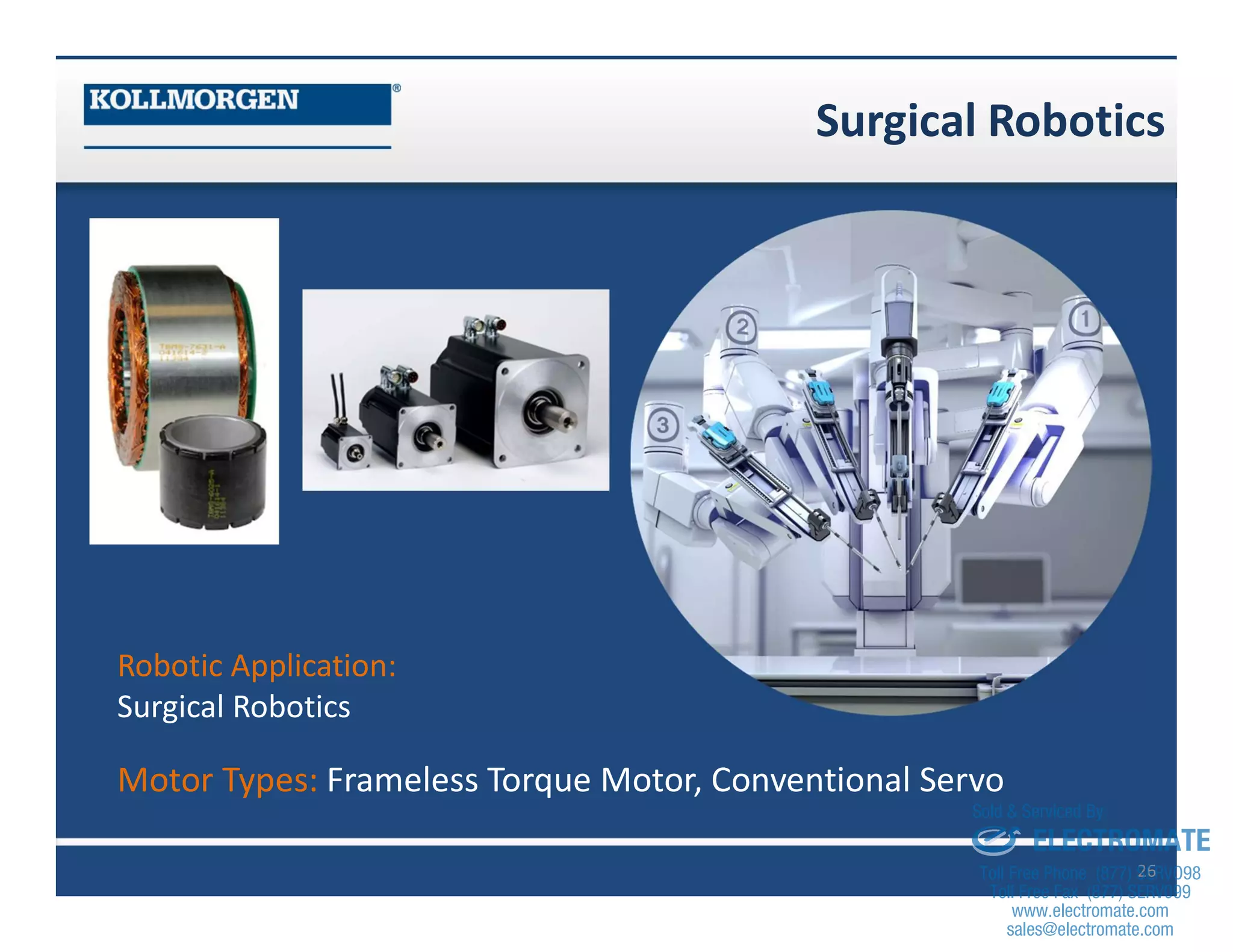

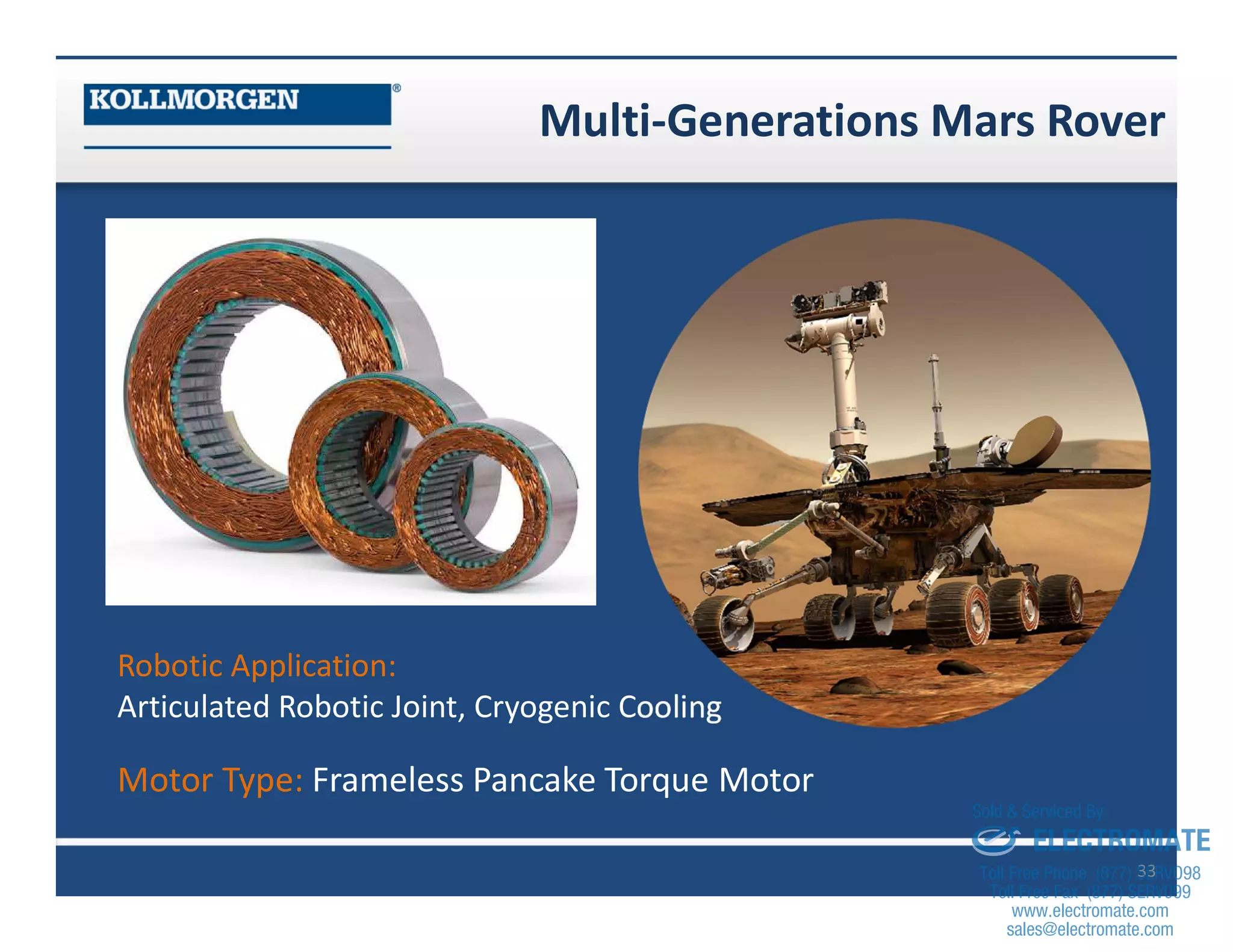

The document discusses how motor design impacts the optimization of robotic systems. It explains that frameless motors can enable smaller, lighter and faster robots through their direct drive capabilities and high torque density. The document also covers various motor topologies and important concepts like torque constant, motor size constant, and how they relate to continuous torque capacity, efficiency and losses. Application examples discussed include collaborative robots, surgical robots, and mobile robots.

![15

How does this relate the Ke (BEMF Constant) ?

They are proportional.

Ke = Volts

_________________________________________________________________________________________________

Unit of Rotational Speed – RPM [or Rad/sec]

Example: V / 1000 RPM

FYI - If working in SI units, these numbers are

identical, Kt in Nm/A = Ke in V-sec / rad

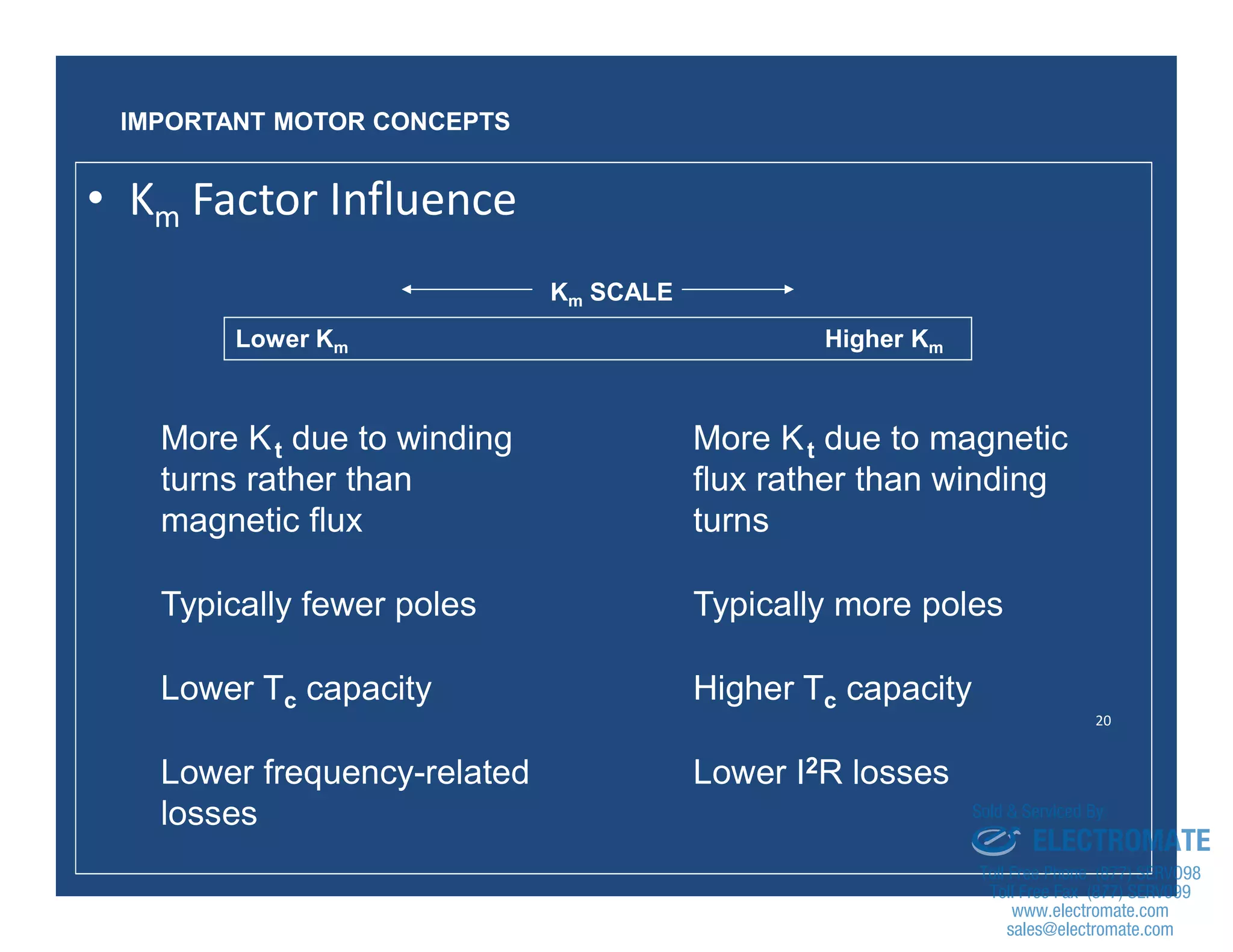

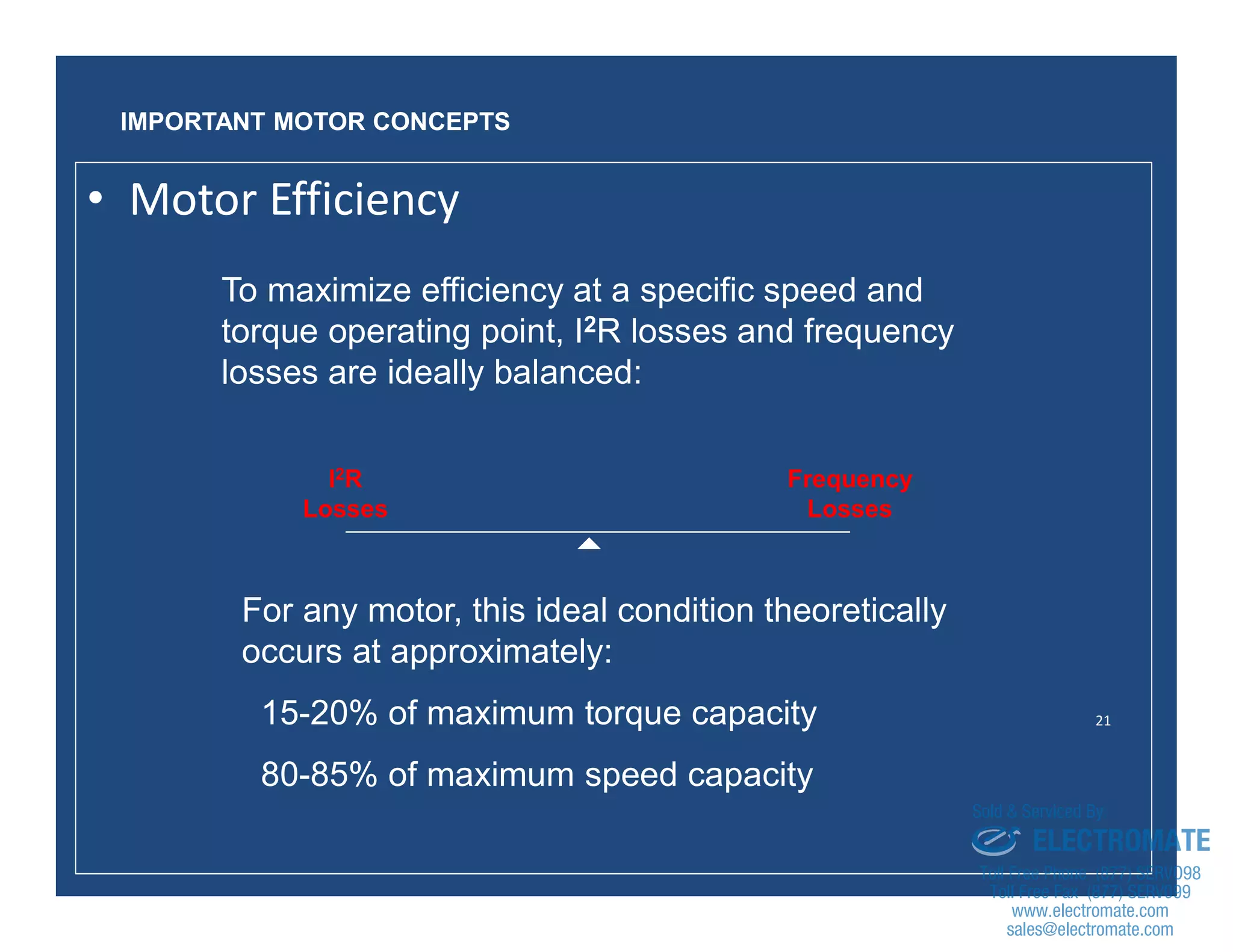

IMPORTANT MOTOR CONCEPTS

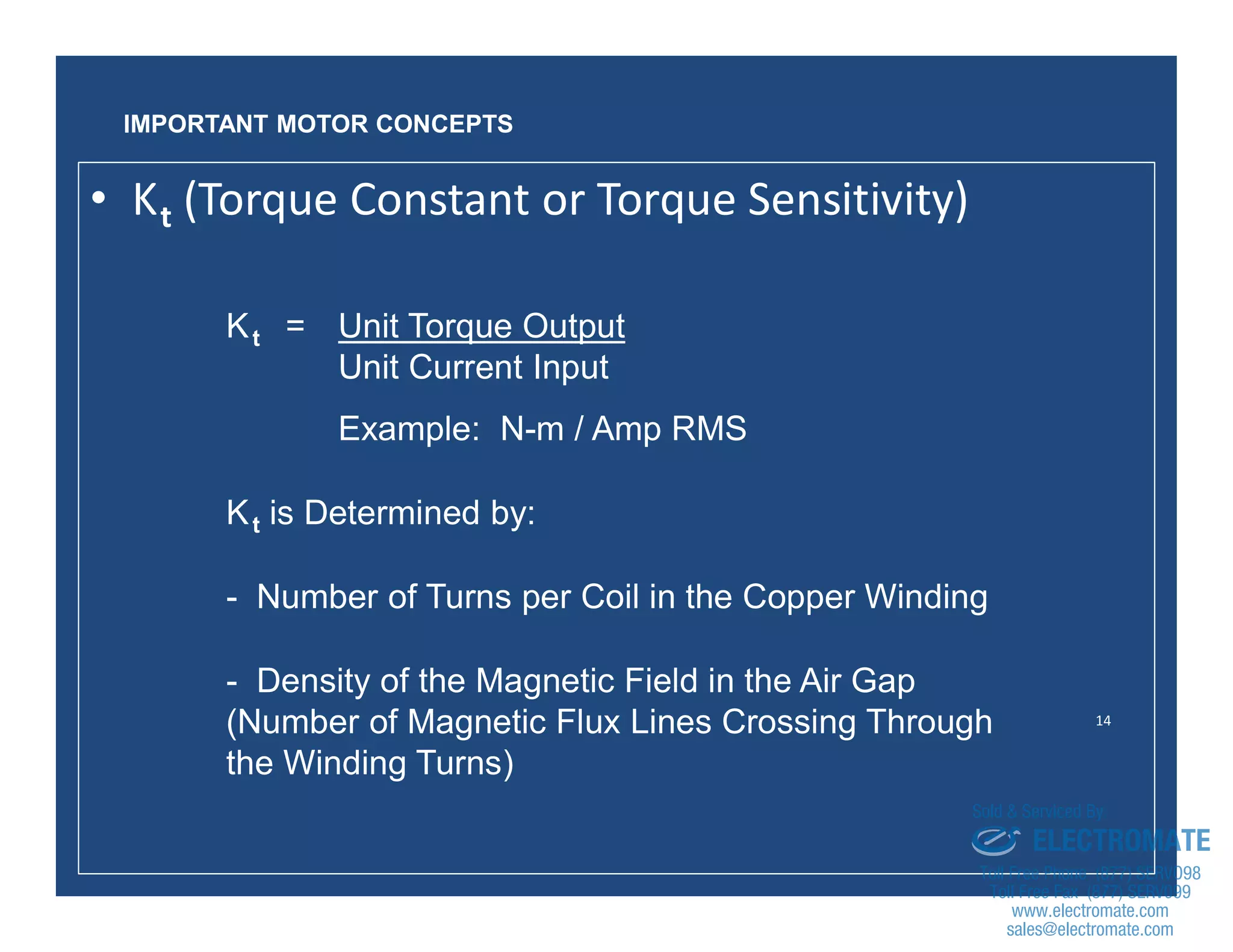

• Kt (Torque Constant or Torque Sensitivity)

sales@electromate.com

www.electromate.com

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:](https://image.slidesharecdn.com/kollmorgen-roboticsymposiumpresentation-motordesignimpactsontheoptimizationofroboticsystems-180403190144/75/Kollmorgen-robotic-symposium-presentation-motor-design-impacts-on-the-optimization-of-robotic-systems-15-2048.jpg)

![37

• Typical Motor with Class F insulation system

has 155 C max winding temperature

• 155 C equates to nominal 140 C in close

proximity to encoder / gearing design elements

• Solutions:

Increase thermal heat sink mass

Increase distance to encoder / gearing [longer thermal

path = increased weight]

Reduce maximum winding temperatures

DEEP DIVE – Collaborative, Articulated Joint Design

• Joint Design Considerations

sales@electromate.com

www.electromate.com

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:](https://image.slidesharecdn.com/kollmorgen-roboticsymposiumpresentation-motordesignimpactsontheoptimizationofroboticsystems-180403190144/75/Kollmorgen-robotic-symposium-presentation-motor-design-impacts-on-the-optimization-of-robotic-systems-37-2048.jpg)